Device and method for detecting hydrogen embrittlement resistance of metal material under dynamic bending condition

A dynamic bending, metal material technology, used in measuring devices, using repetitive force/pulse force to test the strength of materials, analyzing materials, etc. , The effect of shortening the test period and short test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

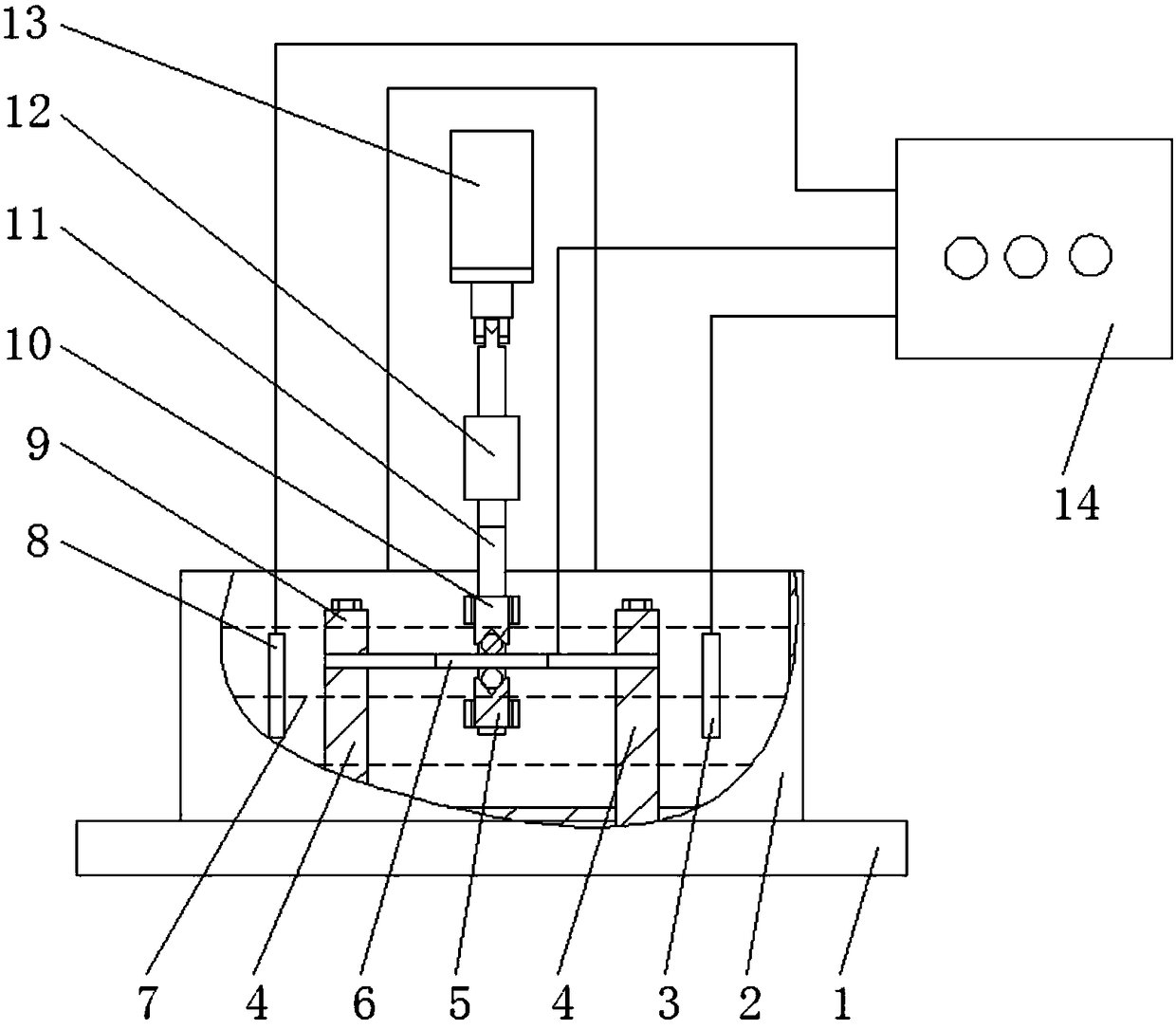

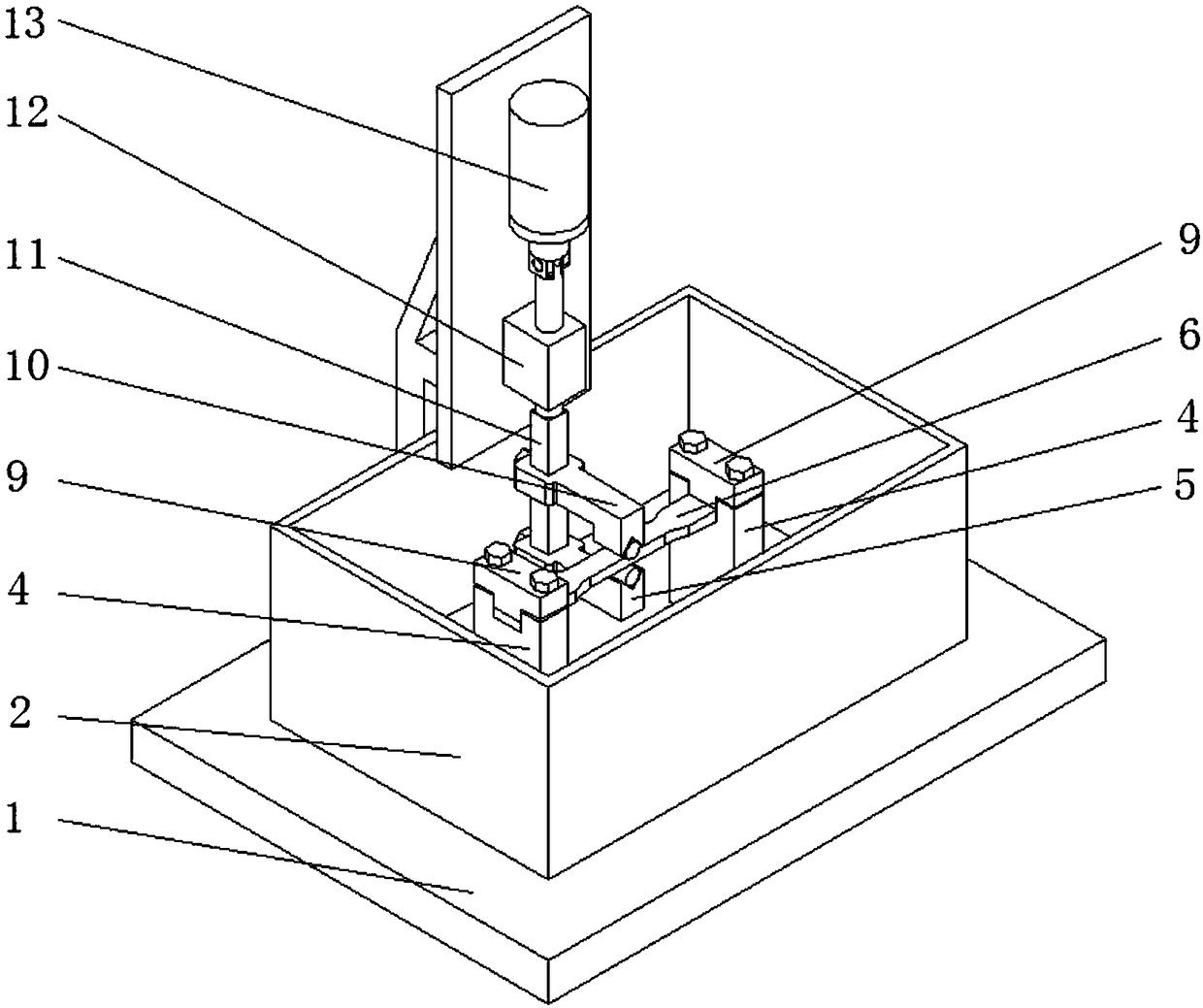

[0056] The device for detecting the hydrogen embrittlement resistance of metal materials under dynamic bending conditions of the present application is composed of a loading device and an electrochemical group, such as figure 2 , 3 shown.

[0057] The electrochemical group consists of a dielectric container 2, a reference electrode 3, a dielectric solution 7, an auxiliary electrode 8, and a potentiostat 14. The dielectric solution can be 0.5mol / L NaOH aqueous solution, and the dielectric container is made of insulating and corrosion-resistant materials. During the test, the sample is immersed in the medium solution, and a constant hydrogen charging current density is used to fill the sample with a constant hydrogen content.

[0058] The loading device is mainly composed of base plate 1, lower support 4, lower chuck 5, upper pressing block 9, upper chuck 10, connecting rod 11, guide block 12, oil cylinder 13 and other components. The lower support 4 and the upper pressing bl...

Embodiment 2

[0065] A method for testing the hydrogen embrittlement resistance of metal materials under dynamic bending conditions, including:

[0066] Step 1. Sample making

[0067] To make a plate-shaped sample, the length of the parallel working part in the middle is required to be greater than twice the thickness, the radius of the transition arc from the parallel working part of the sample to the clamping end is greater than twice the thickness, and the width of the clamping end is slightly different from the width of the 4 slots of the lower support. Small, the length of the sample shall not be less than the distance between the outer facades of the two lower supports 4. The parallelism, coaxiality and perpendicularity of the sample should be less than 5‰ of the thickness of the working section of the sample. The average surface roughness is required to be less than 0.2 μm, and there should be no obvious scratches under 20 times low magnification.

[0068] Step 2. Sample clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com