A honeycomb briquette brick

A technology of honeycomb briquette brick and briquette, which is applied in the petroleum industry, solid fuel, fuel, etc., and can solve the problems of black heart coal, uneven combustion intensity, waste of resources, etc.

Inactive Publication Date: 2014-10-29

张启凤

View PDF9 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] (1). Honeycomb coal is more coal-efficient than bituminous coal and briquettes, but its firepower is not strong:

[0004] 1. They all have such disadvantages: that is, when the new coal is added to the fire, the burning flame is suppressed, and it becomes gas and is discharged from the furnace

[0005] 2. The shape of briquette is only suitable for traditional combustion methods

[0006] 3. The shape of honeycomb coal is only suitable for the use of traditional stoves, and can only produce one burner. This burner burns on the top of the coal and does work directly. This burner is very close to the chimney mouth, and about 30% of the heat energy is discharged into the atmosphere , which is not only a waste of resources, but also pollutes the environment. Therefore, the thermal efficiency of this external combustion method is extremely low

[0007] 4. The structure of briquette makes the combustion intensity too concentrated in the center of the coal, and its combustion intensity is uneven. When the fire is very hot, it causes strong convection of the air, and this strong convection is due to its uneven combustion intensity , resulting in the existence of black heart coal at the bottom of the outer periphery of honeycomb coal.

[0008] 5. The bituminous coal used for burning boilers needs to be added with water, which consumes energy, and the cleanliness of coal combustion is also extremely poor, that is, there is a lot of coal slag

[0009] 6. After the briquette is burned, the cinder is waste, which pollutes the environment.

The disadvantage of the lateral combustion chamber without the furnace cylinder tile is that the flame combustion intensity is low, and it is a red flame or a blue flame.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

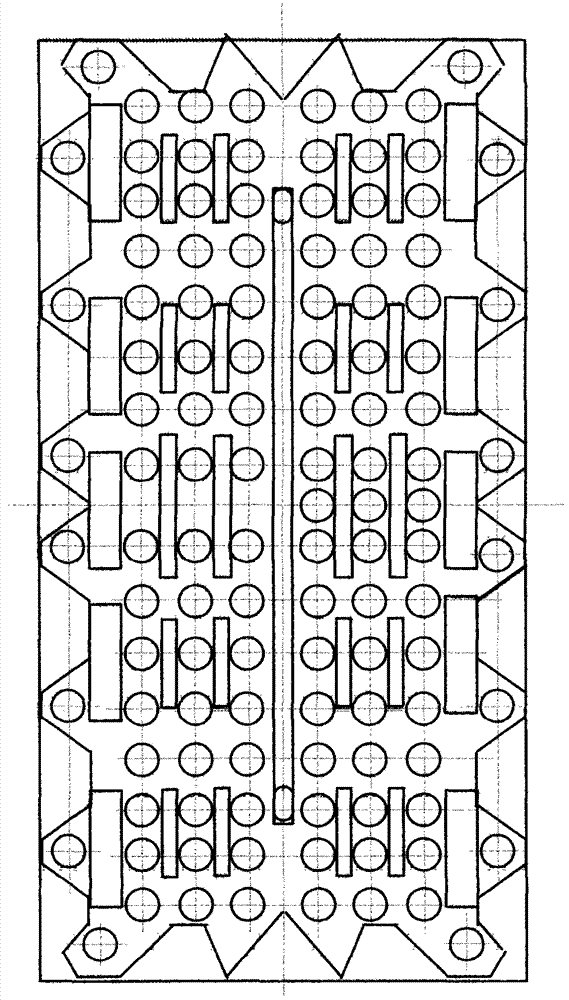

[0099] Mix about 70% of coal powder, about 20% of yellow clay, and about 3% of sand evenly, and then add appropriate amount of water to activate. Then put it into the mold and press it into round briquette bricks, square briquette bricks or rectangular briquette bricks.

[0100] Because of the high burning intensity of honeycomb briquettes, the loess can be scorched, and the sand acts as a reinforcing agent at this time.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

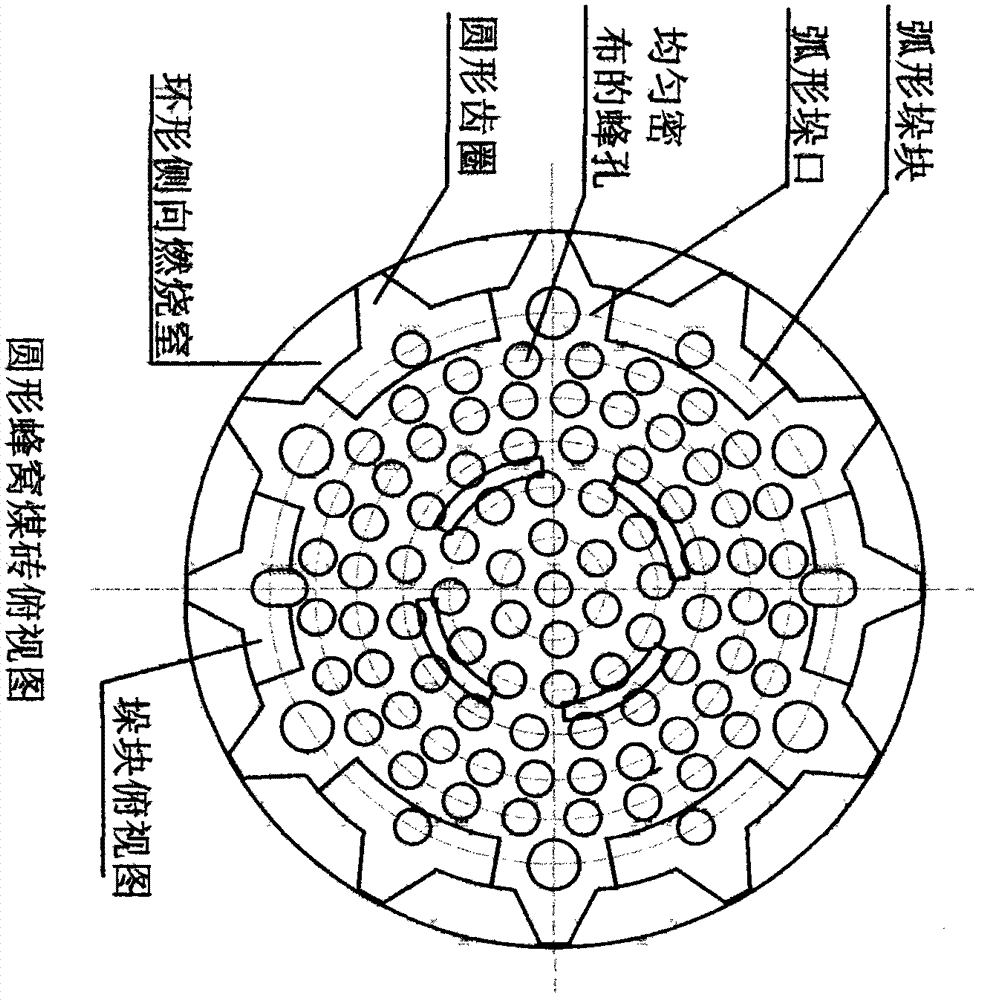

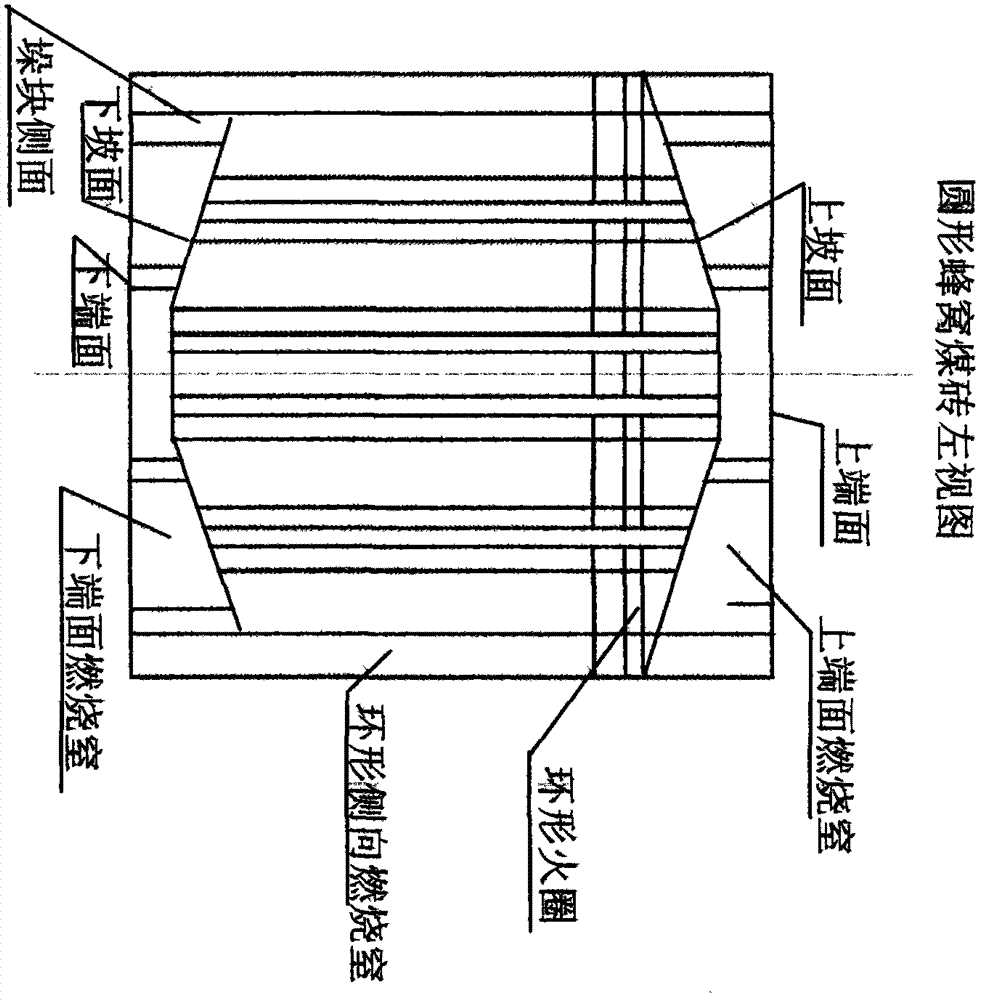

The invention relates to a honeycomb briquette brick and belongs to solid fuel. Compared with honeycomb briquette, the honeycomb briquette brick has innovative combustion chambers so as to generate an epoch-making combustion method that is an internal combustion method. By the internal combustion method, the heat efficiency generated by the honeycomb briquette brick is extremely high, the combustion strength is high, and fault coal even coal gangue can be adopted as a combustion material. The honeycomb briquette brick can be combusted continuously, no black smoke generates when a new honeycomb briquette brick is added, and the flame combustion is not influenced. Coal gas is combusted when the honeycomb briquette brick is combusted, thus achieving zero emission. A brick which is a building material is discharged after the honeycomb briquette brick is combusted. The honeycomb briquette brick is free of dust discharge and coal cinder discharge. The honeycomb briquette brick fundamentally improves the environment. The honeycomb briquette brick allows a tube furnace to be compact in structure and simplified and to have characteristics of small size, light weight, small floor space, easy manufacturing and low total cost. The upper and lower parts of the honeycomb briquette brick are provided with end-surface combustion chambers. The external side surface of the honeycomb briquette brick is an annular side combustion chamber. The honeycomb briquette brick is covered by the combustion chambers, namely, the honeycomb briquette brick is combusted while being covered by flame. The honeycomb briquette brick is widely used for various coal furnace appliances.

Description

[0001] Technical field involved [0002] The present invention relates to briquette, bituminous coal and briquettes, in particular to the shape and structure of a novel briquette brick. Background technique [0003] (1). Honeycomb coal is more coal-efficient than bituminous coal and briquettes, but its firepower is not strong: [0004] 1. They all have such shortcoming: namely, when adding new coal to the continuation of the fire, the burning flame is suppressed and turned into coal gas and discharged from the furnace. In fact, this soot is simply gas. Under the traditional concept, this phenomenon is justified and inevitable. People don't think this is a waste of resources. This kind of smoking is very serious to air pollution. After more than ten minutes of smoking, the flames reappeared. And these ten minutes of gas waste are not counted in the coal resources. Because people always think that they are burning coal, not gas. Therefore, when calculating the cleanliness...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10L5/36

Inventor 张启凤

Owner 张启凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com