Spray type steam generator

A steam generator and spray type technology, applied in the field of spray type steam generators, can solve the problems of long start-up time, large water capacity, low thermal efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

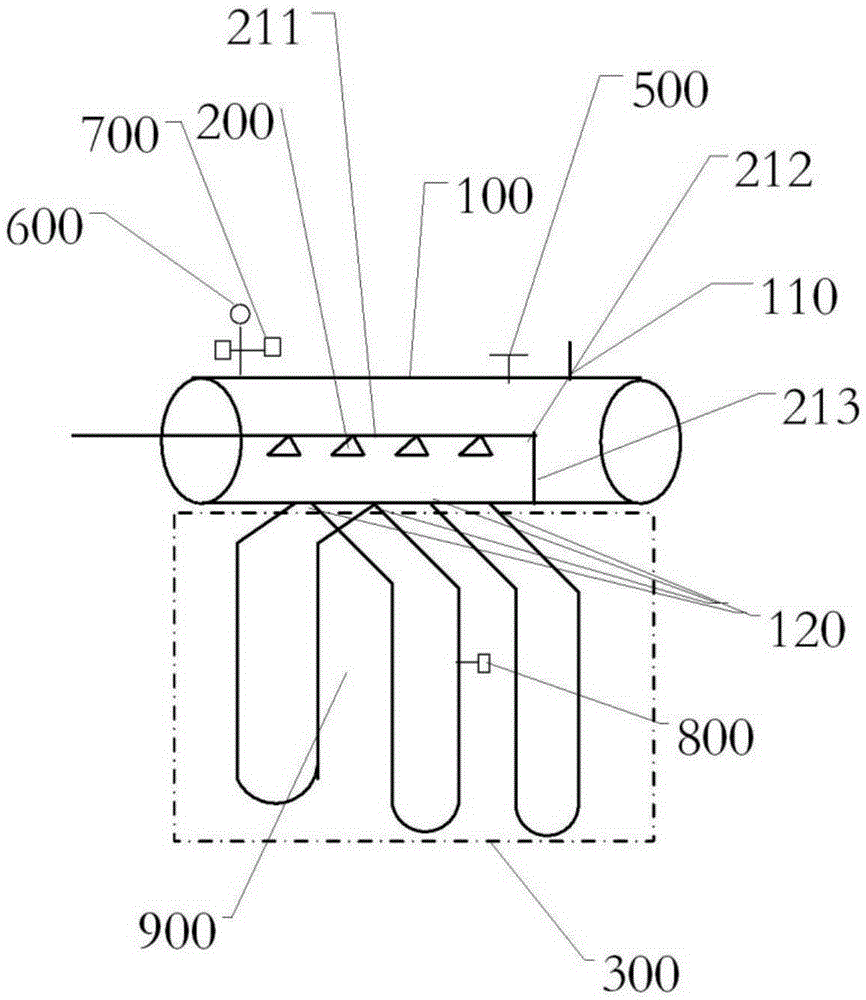

[0035] The invention provides a spray steam generator, such as figure 1 As shown, it includes: an upper header 100, a water supply pipeline 211, four nozzles 200 and a pipe row 300, wherein the water supply pipeline 211 and the four nozzles 200 form a spraying device, and the water supply pipeline 211 is located in the middle of the upper header , one end of which is welded to the side wall of the upper header 100 through a flange, and the other end 212 is fixed to the lower wall of the upper header through a base 213 . Those skilled in the art will understand that the water supply pipeline can also be fixedly arranged in the upper header by other fixing methods in the field, thereby ensuring the safety of the entire device; the water supply pipeline 211 can be connected to a water pump for supplying water, and the other end 212 can be a closed end or can be connected to a nozzle; the pipe row 300 is arranged under the upper header 100, and communicates with the upper header 1...

Embodiment 2

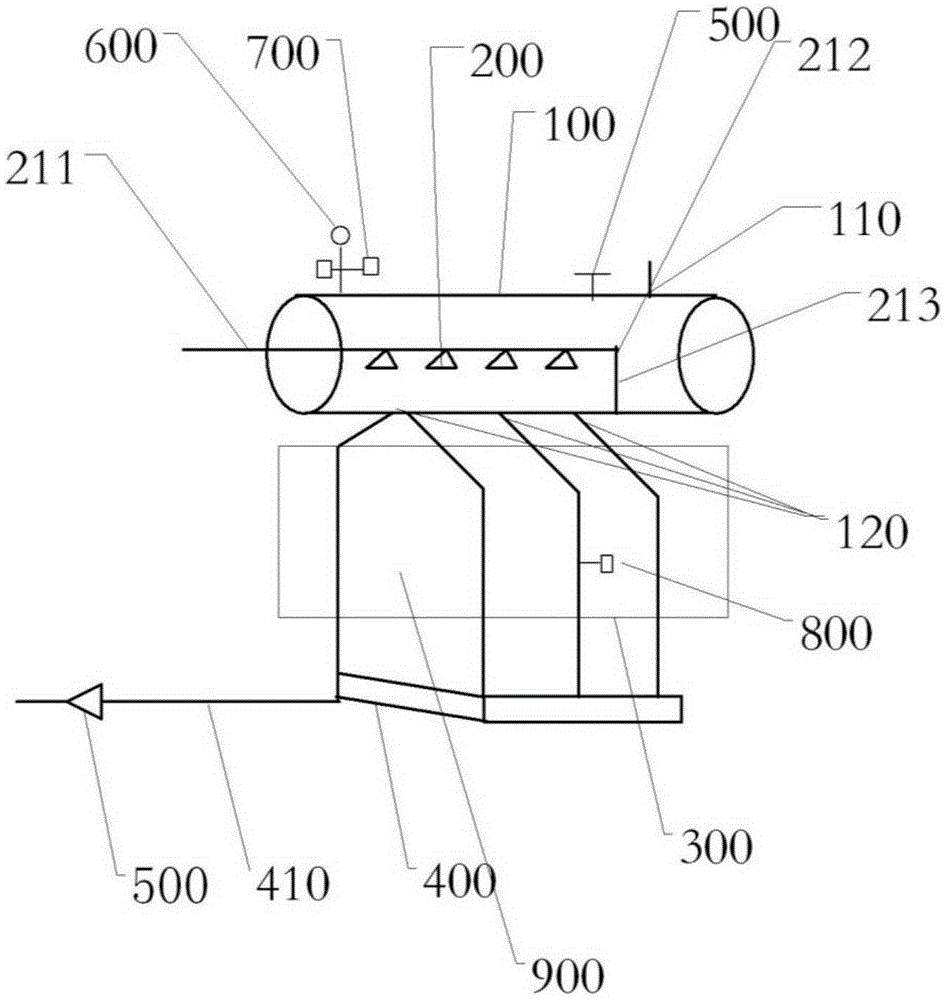

[0038] The invention provides a spray steam generator, such as figure 2 As shown, on the basis of Embodiment 1, this embodiment further includes a lower header 400. The lower header 400 communicates with the pipe row 300 through a plurality of interfaces, and is used to receive the unvaporized liquid in the steam generator. The lower header 400 is provided with an outlet pipe 410 to discharge the liquid water in the lower header, and a drain valve 500 is provided on the outlet pipe 410 to ensure the lower header while discharging the liquid water in the lower header. The steam present in the tank is not vented, thus ensuring maximum utilization of the steam throughout the device without leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com