Control method for steam production process and pipeline directly-heated type steam generator

A technology of steam generation device and production process, applied in steam generation, steam boilers, control systems, etc., can solve the problems of inability to convert electric energy into heat energy, environmental pollution, heat transfer area and water storage constraints, etc., to achieve convenient and rapid control, Avoid explosion hazard, control effect with small delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

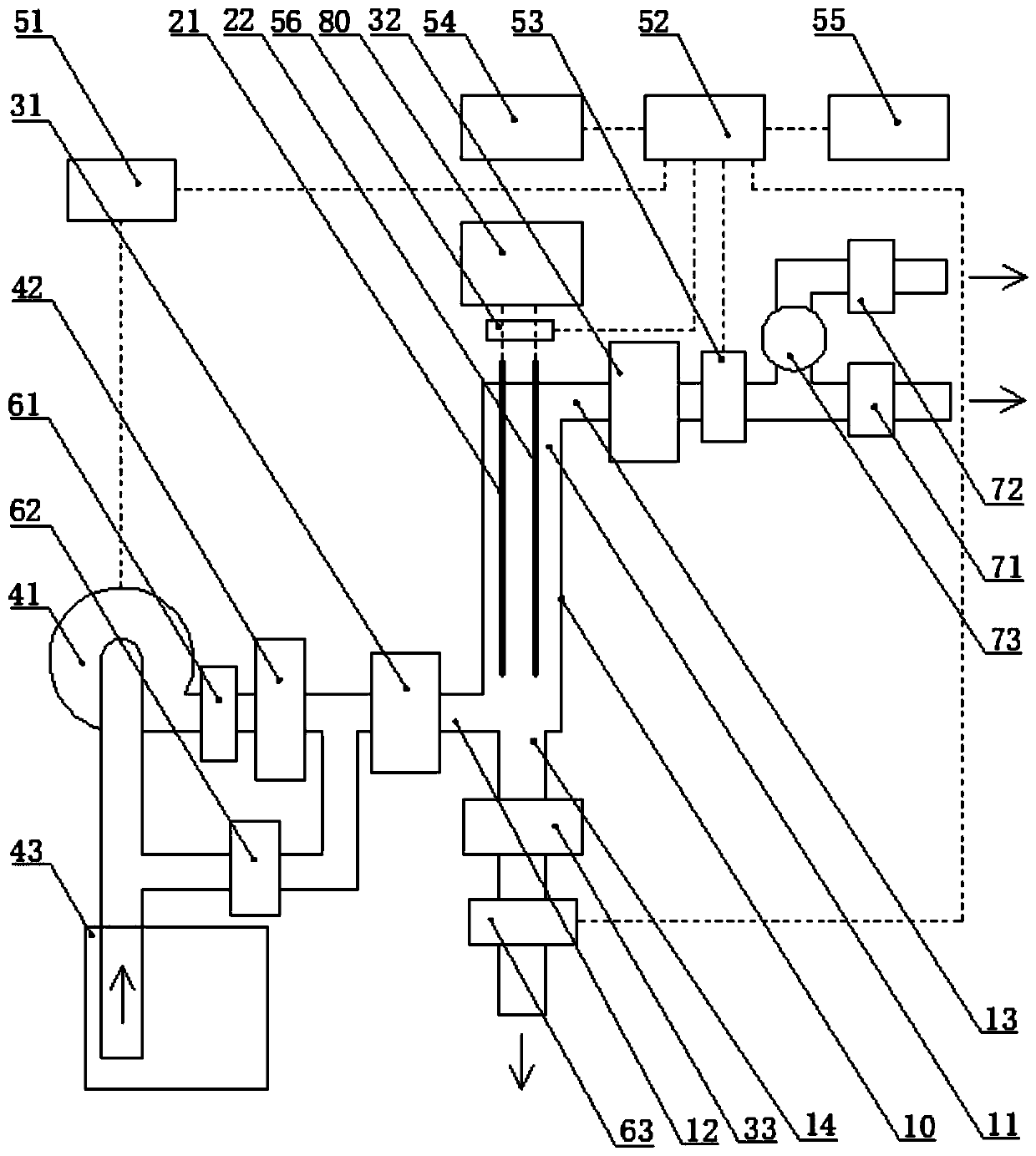

[0119] (8) As a specific embodiment of the pipeline-type direct-heating steam generating device provided by the present invention, the pipeline-type direct-heating steam generating device includes:

[0120] The evaporator 10 is provided with an evaporation cavity 11 inside, and is provided with a water inlet 12, a steam outlet 13, and a drain 14 respectively communicated with the evaporation cavity 11;

[0121] Several electrodes are arranged inside the evaporation chamber 11;

[0122] The drainage component 63 is an electronically controlled component, which is arranged on the drain port 14 and is used to discharge the water in the evaporator 10;

[0123] The current detection module 56 and the voltage detection module are arranged inside or outside the evaporation chamber 11, and are used to detect the current and voltage in the evaporation chamber 11;

[0124] Water pump 41, the output end is connected with water inlet 12;

[0125] The speed governor 51 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com