Axial split-phase hybrid excitation type magnetic suspension motor control system

A technology of mixed excitation and axial phase separation, which is applied in the control system, AC motor control, general control strategy, etc., can solve the problems of large vibration, large torque pulse of switched reluctance motor, etc., and achieves fast response and saves Effects that control lag, improve development speed, and run performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

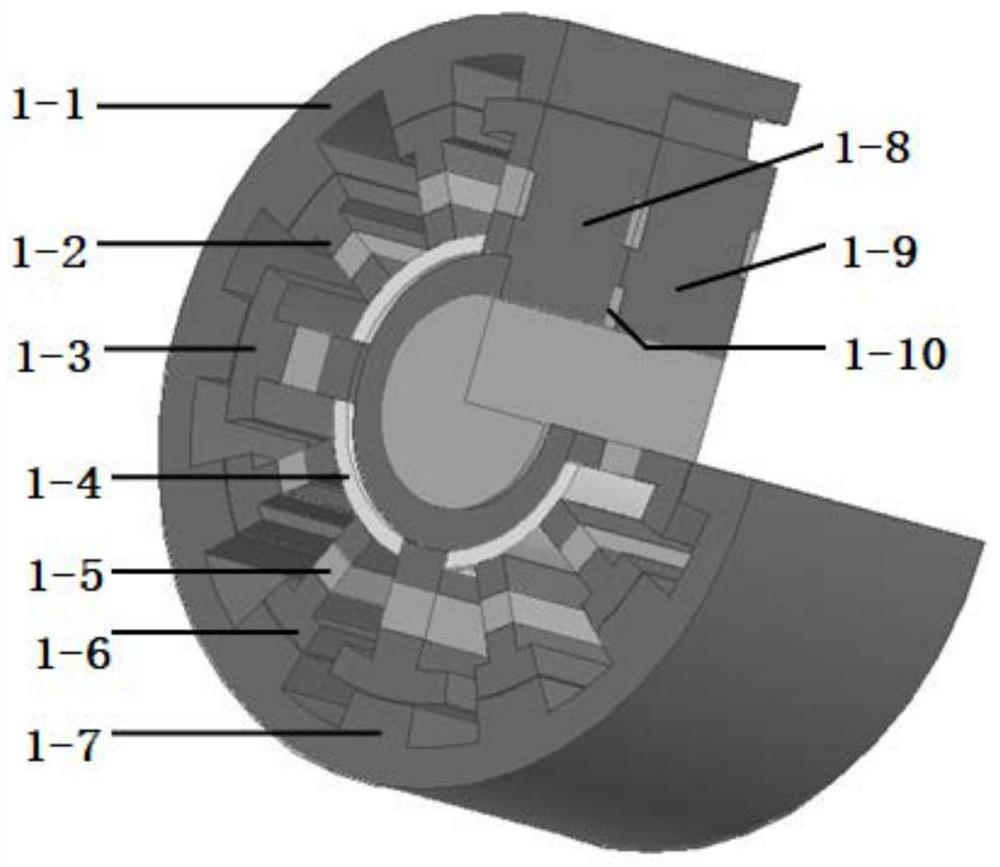

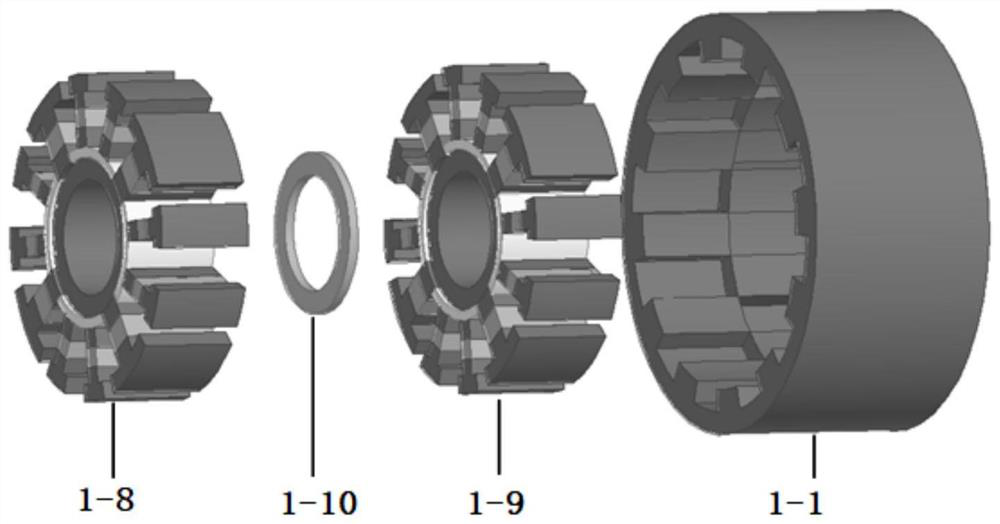

[0042] The following technical solutions of the present invention in conjunction with the accompanying drawings will be further described.

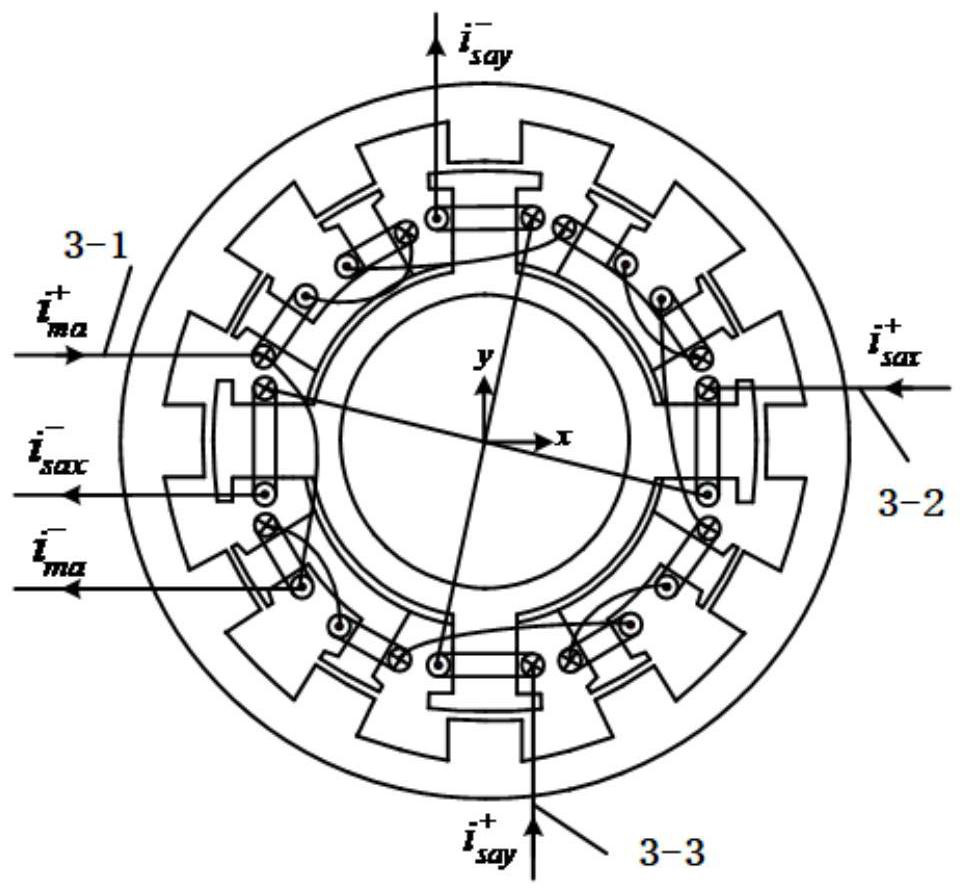

[0043] Axial split-phase hybrid excitation type magnetic levitation motor control system described in the present invention, comprising the following modules: position sensor, displacement sensor, torque and levitation force estimation module, second-order sliding mode controller, hysteresis comparator, pulse generation module and power converter;

[0044] The position sensor acquires the real-time position angle θ of the rotor of the axial split-phase hybrid excitation type magnetic levitation motor, and obtains the speed ω of the motor by differential rotor position angle θ;

[0045] The displacement sensor consists of eight eddy-current displacement sensors whose role is to measure the rotor radial four-degree-of-freedom eccentric displacement (xA ,y A ,x B ,y B Eight eddy-current displacement sensors are installed radially at both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com