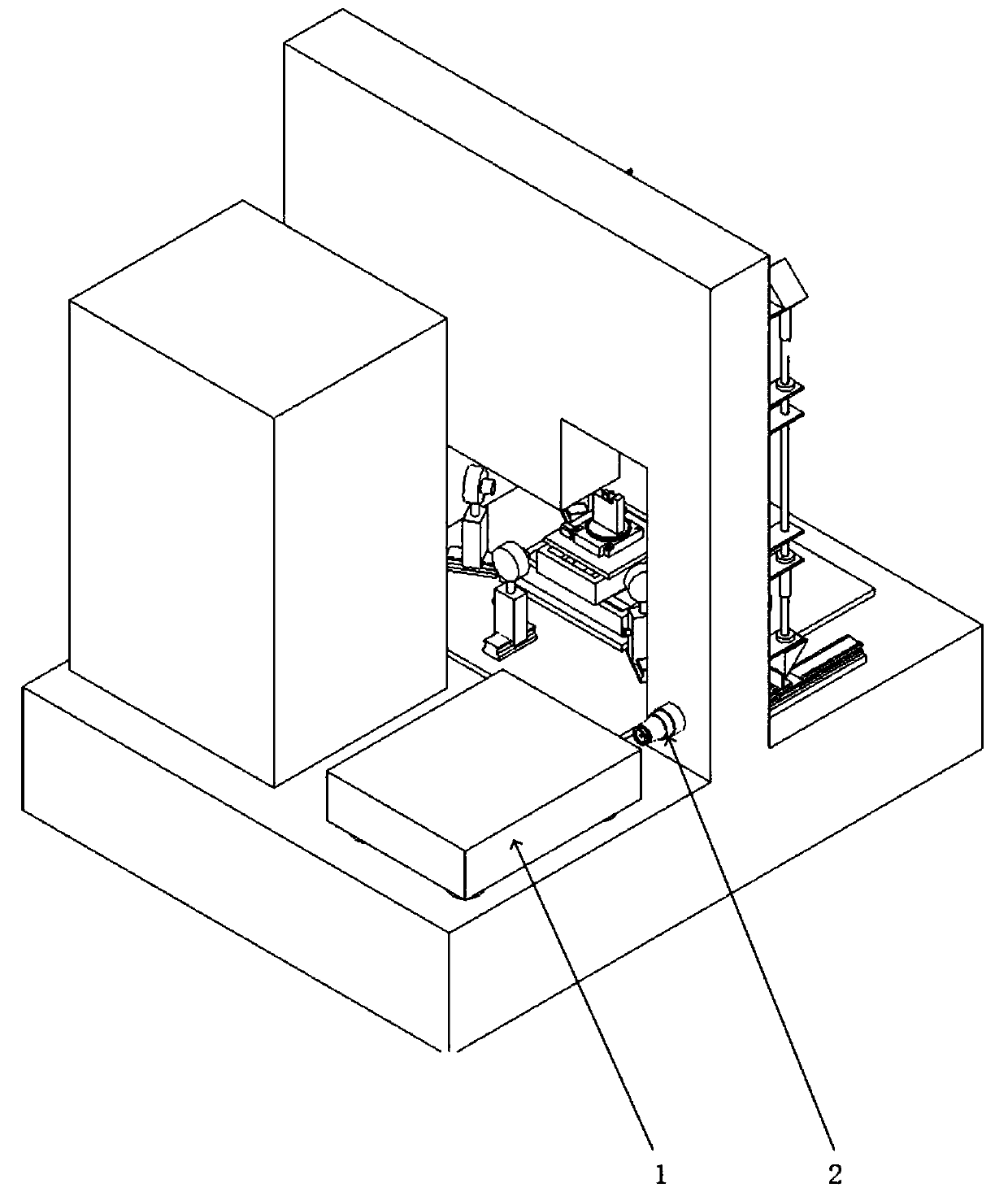

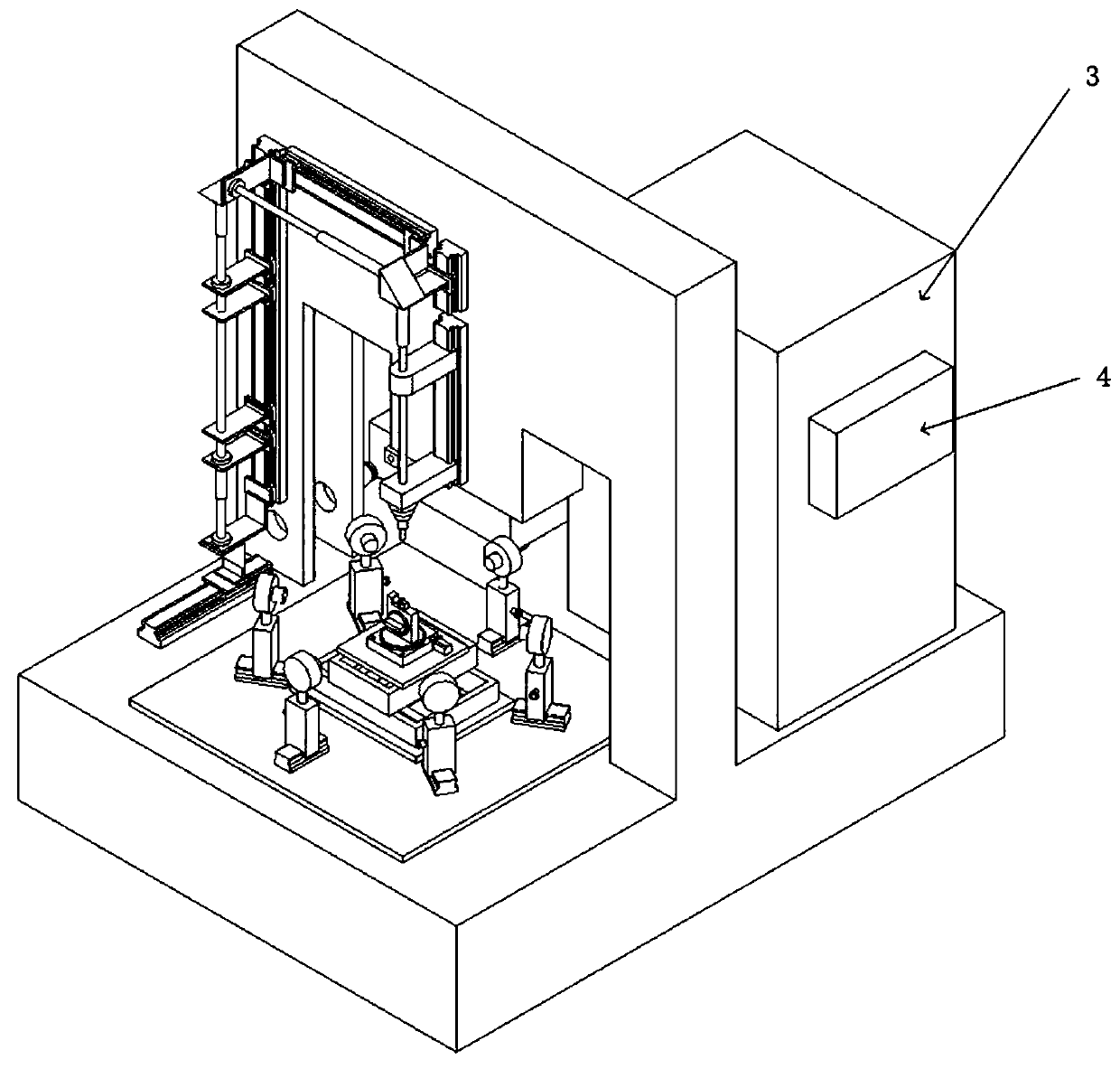

Laser induced plasma assisted electric spark compound processing device and laser induced plasma assisted electric spark compound processing method under action of magnetic field

A plasma and laser-induced technology, applied in the direction of electric processing equipment, accessory devices, metal processing equipment, etc., can solve the problems of difficult to achieve cross-scale processing, insufficient quality of processed surface, difficult to process low conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

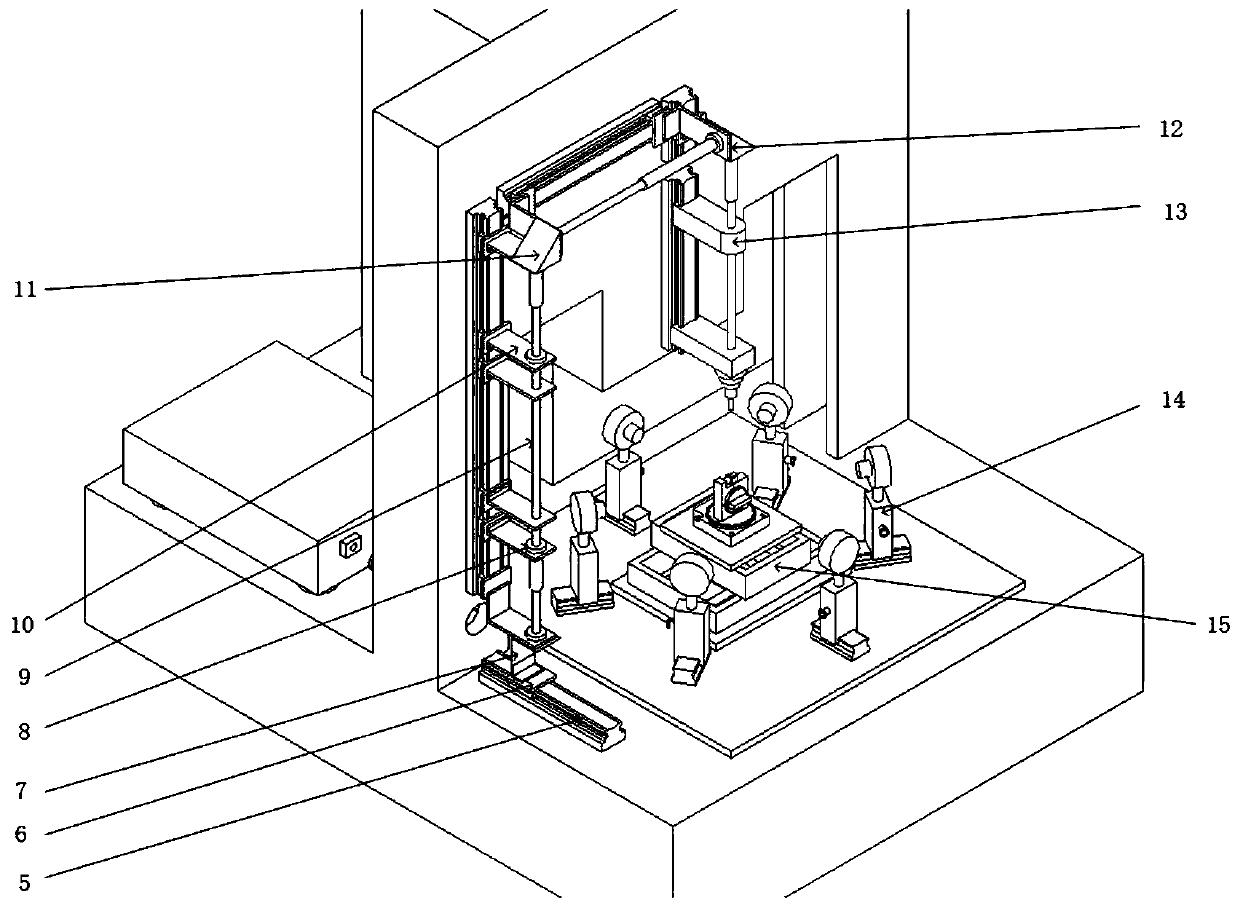

[0066] Processing environment: The EDM machine tool is AgieCharmilles’ FORM E350 high-performance EDM machine tool. The metal workpiece to be processed is titanium alloy Ti6Al4V, a difficult-to-machine material with a thickness of 10 mm; a cylindrical hole with a diameter of 20 μm and a depth of 10 μm is processed .

[0067] The pulse current pulse width provided by the EDM machine tool is 30μs, the pulse interval is 20μs, and the current is 6A. The current accuracy of the DC excitation power supply (connected to the electromagnet) is 10mA, and it can provide a current of 0-8A and a voltage of 0-10V. The direct current, the output power is 300W. It also includes ultrashort pulse lasers, optical path conversion components, five-degree-of-freedom precision platforms, and multiple pairs of electromagnets. The wavelength of the laser beam is 532nm, the frequency is 10KHz, the pulse width is 10ps, and the pulse energy is 3μJ. It is cooled by water cooling. The center of the chuck...

Embodiment 2

[0070] Processing environment: The EDM machine tool is AgieCharmilles' FORM E350 high-performance EDM machine tool. The metal workpiece to be processed is a difficult-to-machine material with a thickness of 5mm, which is 65% aluminum-based silicon carbide (low conductivity material). A cylindrical hole with a diameter of 0.5mm.

[0071] The pulse current pulse width provided by the machine tool is 40μs, the pulse interval is 30μs, and the current is 8A. The current accuracy of the DC excitation power supply of the auxiliary device used is 10mA, which can provide a current of 0-8A and a voltage of 0-10V. It is 300W; it also includes ultra-short pulse laser, electromagnet group, optical path conversion component, five-degree-of-freedom precision platform, electromagnet wire package spacing 80mm, electromagnet pole head diameter 12mm, two pole spacing adjustable within 80mm, the maximum can generate 1T magnetic field; the magnetic induction intensity of the generated magnetic fie...

Embodiment 3

[0074] Processing environment: The EDM machine tool is AgieCharmilles' FORM E350 high-performance EDM machine tool. The metal workpiece to be processed is nickel alloy, a difficult-to-machine material with a thickness of 10mm; a cylindrical hole with a diameter of 2mm is processed.

[0075] The pulse current pulse width provided by the machine tool is 50μs, the pulse interval is 40μs, and the current is 10A. The current accuracy of the DC excitation power supply of the auxiliary device used is 10mA, which can provide a current of 0-8A and a voltage of 0-10V. It is 300W; it also includes an ultra-short pulse laser, an optical path conversion component, an electromagnet group, and a five-degree-of-freedom precision platform. The wavelength of the laser beam is 532nm, the frequency is 10KHz, the pulse width is 10ps, and the pulse energy is 6μJ. Cooling, the optical path conversion component guides the laser beam from the ultrashort pulse laser into the machine tool, the laser beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com