Weaving material and preparation method thereof

A technology of weaving materials and raw materials, which is applied in the manufacture of rayon, textiles and paper, and conjugated synthetic polymer rayon. It can solve the problems of limited application range, low appearance and texture, and environmental pollution, and achieve improved dispersion. , fog effect is obvious, the effect of excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

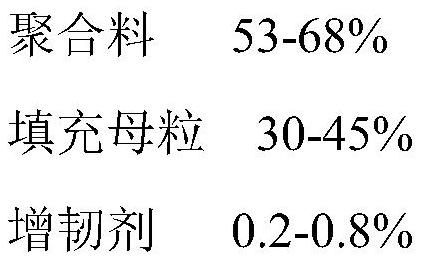

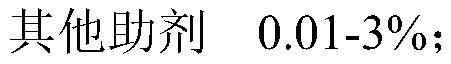

Method used

Image

Examples

Embodiment 1

[0054] A kind of braided material is prepared by the following steps:

[0055] Step (1): 45.00kg of polypropylene, 9kg of polyethylene, 45g of calcium carbonate, 0.5kg of acrylonitrile-butadiene-styrene copolymer and 0.5kg of colorant are dried respectively, then mixed and added to The feeding section of the extruder, the feeding section controls the temperature at 155°C, then enters the melting section, and controls the temperature at 190°C, then enters the homogenization section, controls the temperature at 220°C, and finally extrudes through a die with a temperature of 220°C , from feeding, melting, homogenizing to die extrusion, the duration of the whole process is controlled at 5 minutes; after extrusion, the film is produced, and the film is obtained;

[0056] Step (2): Cut and stretch the diaphragm obtained in step (1), control the stretching ratio to 1:2.2, and obtain a braided material with a thickness of 0.03mm and a linear density of 60tex, and finally the braided m...

Embodiment 2-3

[0058] The difference between Embodiments 2-3 and Embodiment 1 above is that the material of the weaving material in this embodiment is different from that in Embodiment 1. For details, refer to the parameters in Table 2.

Embodiment 4-5

[0060] The difference between Examples 4-5 and the above-mentioned Example 2 is that: the preparation process conditions of the braided material in this example are different from those in Example 2, see the parameters in Table 2 for details.

[0061] The material parameter and process parameter table of table 2 embodiment 1-5

[0062]

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com