Matte TPU (Thermoplastic Polyurethane) material and preparation method thereof

A matte agent and raw material technology, which is applied in the field of matte TPU materials and its preparation, can solve the problems of uneven dispersion, loss of material toughness, and high requirements for TPU materials, and achieve high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

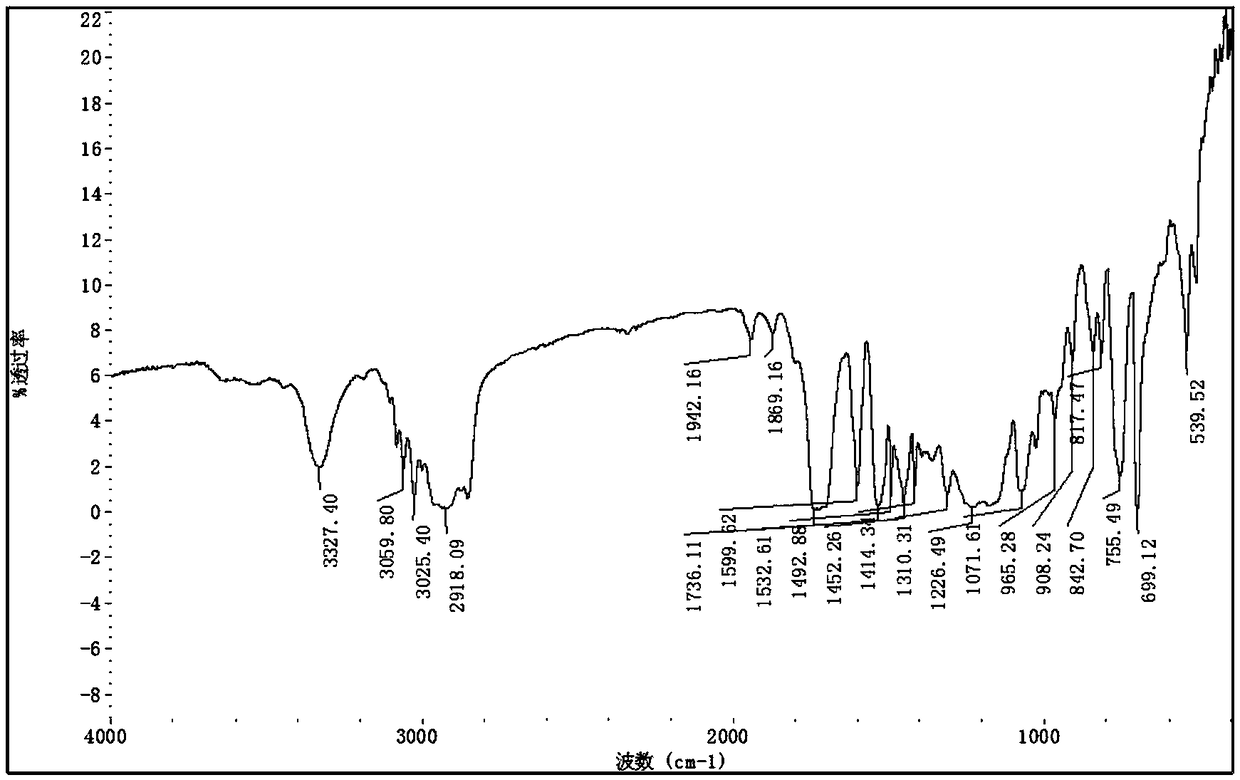

Image

Examples

preparation example Construction

[0039] In a preferred embodiment, the polyurethane fogging agent masterbatch also includes 5 to 8 parts by weight of an auxiliary agent; preferably, the auxiliary agent is silicon dioxide; more preferably, the silicon dioxide The particle size is 70-120nm; more preferably, the silica is modified silica; more preferably, the modified silica is hyperbranched polyurethane modified silica, and its preparation method includes the following step:

[0040] (1) Add 80 parts by weight of N,N-dimethylformamide and 3 parts by weight of silicon dioxide into a three-necked flask, stir and ultrasonically disperse for 15 minutes, and add 1 part by weight of silane coupling agent dropwise under stirring and 10ml of deionized aqueous solution containing 10wt% triethylamine, then the system was heated to 150°C, refluxed for 4 hours, filtered, washed with ethanol, and dried to obtain modified silica;

[0041] (2) Take 1.8 parts by weight of the above-mentioned modified silica and add it to 100 ...

Embodiment 1

[0058] Embodiment 1 provides a kind of polyurethane fogging agent masterbatch, the preparation raw material of described polyurethane fogging agent masterbatch, comprises polyurethane 40, styrene-ethylene-butadiene-styrene copolymer 38, Acrylate Copolymer12.

[0059] The styrene-ethylene-butadiene-styrene copolymer is the SEBS product of Taiwan Taiwan Rubber brand No. 3152H, wherein the styrene content is 29wt%, and the viscosity in 25wt% toluene solution is 1.20Pa.s; Polyurethane is the product of Duterun Trading (Shenzhen) Co., Ltd.'s brand name 8585; the acrylate copolymer is made of methyl methacrylate, butyl acrylate and butyl methacrylate in a weight ratio of 6:1.5:0.2. The comonomer is prepared by the conventional preparation method described in the present invention.

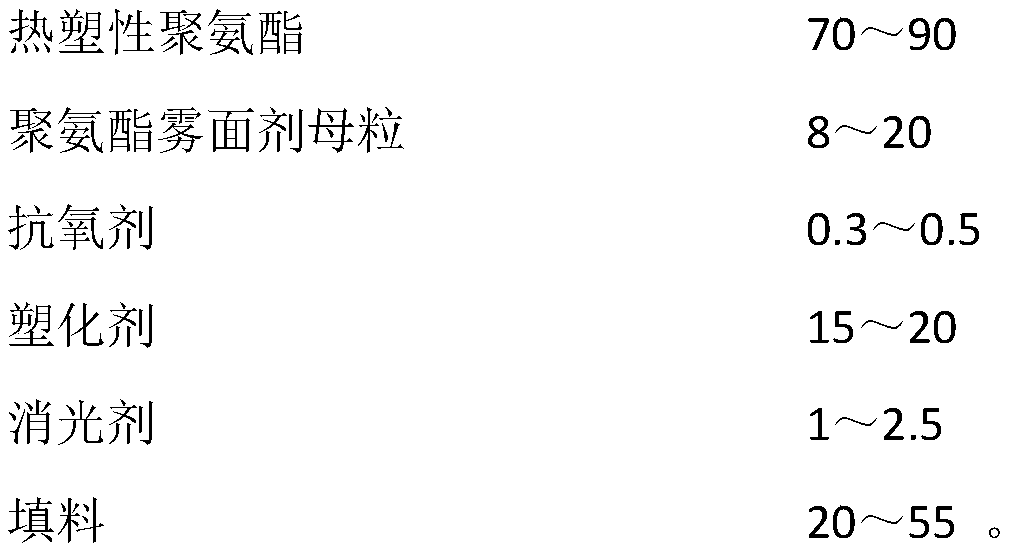

[0060] This example also provides a kind of matte polyurethane composition, the raw material of described matte polyurethane composition, by weight, comprises

[0061]

[0062] The thermoplastic polyu...

Embodiment 2

[0064] Embodiment 2 provides a kind of polyurethane fogging agent masterbatch, the preparation raw material of described polyurethane fogging agent masterbatch, comprises polyurethane 50, styrene-ethylene-butadiene-styrene copolymer 45, Acrylate Copolymer 18.

[0065] The styrene-ethylene-butadiene-styrene copolymer is the SEBS product of Li Changrong chemical industry brand 9551, wherein the styrene content is 33wt%; the polyurethane is the 8585 brand of Duterun Trading (Shenzhen) Co., Ltd. The product; The acrylate copolymer is composed of methyl methacrylate, butyl acrylate and butyl methacrylate in a weight ratio of 6:2.5:0.8 as comonomers, through the conventional preparation method described in the present invention prepared.

[0066] This example also provides a kind of matte polyurethane composition, the raw material of described matte polyurethane composition, by weight, comprises

[0067]

[0068] The thermoplastic polyurethane is Taiwan Hongyi brand PU68DJ prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com