Remote distribution underground mining emulsion matrix, emulsion explosive and preparation method thereof

A latex matrix and emulsified explosive technology, which is applied in explosive processing equipment, explosives, offensive equipment, etc., can solve the problems of high investment cost, difficult drug delivery, high viscosity, etc., reduce risk factors, reduce blasting costs, and be practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

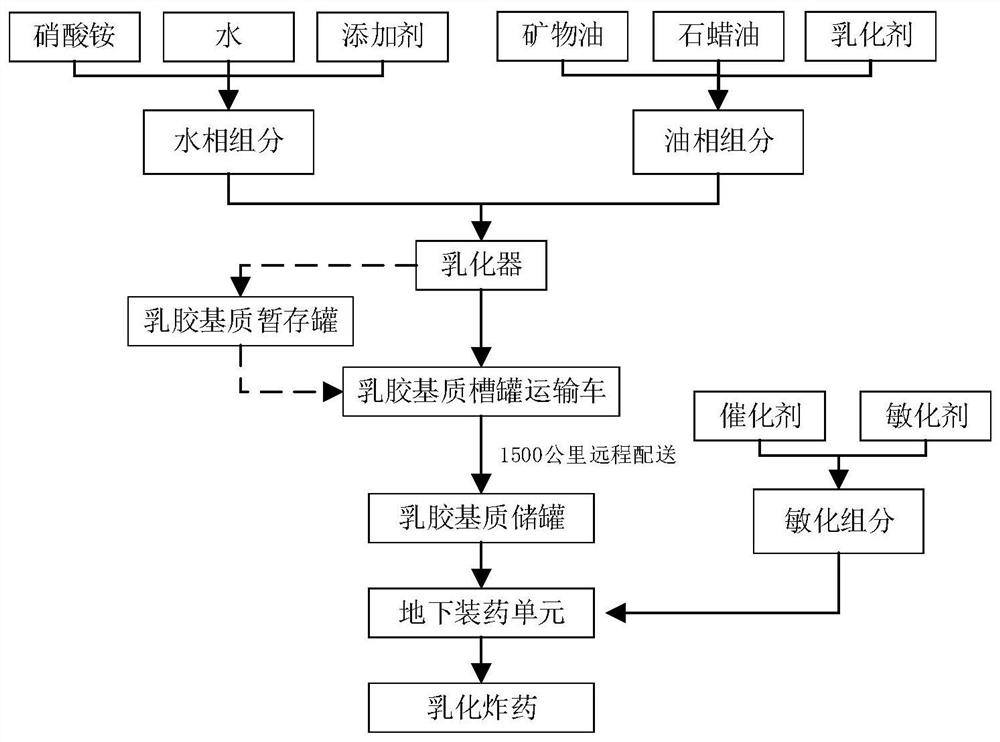

[0035] Such as figure 1 As shown, the present invention also provides a method for preparing a latex matrix for remote distribution underground mines, which includes the following steps:

[0036] 1) Water phase preparation: Keep the water temperature at 85-90°C, add ammonium nitrate and water phase additives in sequence, stir and dissolve to form the water phase, keep it warm for later use;

[0037] 2) Oil phase preparation: add mineral oil and paraffin oil to the oil phase preparation tank, heat to 30~50℃ and stir, add high molecular emulsifier and low molecular emulsifier according to the proportion, and stir evenly to form an oil phase, and control the temperature Keep warm at 30~50℃;

[0038] 3) Adjust the flow rate of the pump according to the ratio of the water phase and the oil phase, adjust the speed of the emulsifier according to the viscosity of the target latex matrix, pump the water and oil phases to the emulsifier, and form a latex matrix after emulsification. Among them...

Embodiment 1

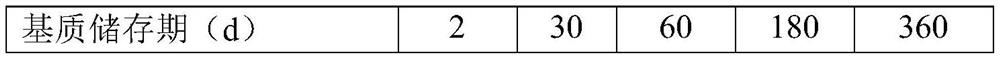

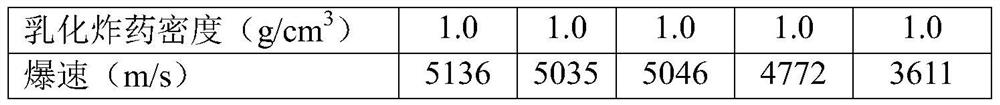

[0052] Add 2700kg of water into the water phase preparation tank, heat it to 85°C, then add 15300kg of ammonium nitrate and stir to dissolve, then add 20kg of aqueous phase additive sodium thiocyanate aqueous solution to mix evenly, keep warm for later use; sequentially add 652kg of mineral oil, 39.3kg of paraffin oil, Add 260.9kg of LUBRIZOL 27001M emulsifier into the oil phase preparation tank, heat it to 55°C, stir well and mix well and keep warm for later use. Adjust the flow ratio of the water phase and oil phase pumping system to 93:7, in which the flow rate of the water phase pumping system is 46.75kg / min and the flow rate of the oil phase pumping system is 3.52kg / min. The rotation speed of the emulsifier is set to 950r / min, and the emulsified latex matrix is cooled to 45°C by a water-cooling exchanger, and then pumped to the latex matrix temporary storage tank or the latex matrix tank transport vehicle. Use a special tanker to transport the latex matrix to the mine wi...

Embodiment 2

[0054] Put 4500kg of water into the water phase preparation tank, heat it to 90℃, then add 13500kg of ammonium nitrate and stir to dissolve, then add 40.5kg of water phase additives to mix well, keep warm for later use; sequentially add 480kg of mineral oil, 480kg of paraffin oil, and 60kg of SMO emulsifier , 180kg of EX9126 emulsifier is added to the oil phase preparation tank, heated to 50°C, fully stirred and mixed uniformly, and kept warm for later use. Adjust the flow ratio of the water phase and oil phase pumping system to 94:6, where the water phase pumping system flow rate is 240kg / min, and the oil phase pumping system flow rate is 15.32kg / min. The rotation speed of the emulsifier is set to 1350r / min, and the emulsified latex matrix is cooled to 45°C through a water-cooled exchanger, and then pumped to the latex matrix temporary storage tank or the latex matrix tank transport truck. Use a special tanker to transport the latex matrix to the mine within 1500 kilometers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com