Spot welding sealing foaming rubber pad for vehicle

A foamed rubber and spot welding technology, applied in the field of vehicle spot welding, can solve the problems of inconvenient construction, affecting the accuracy of spot welding in the working environment, noise and vibration, etc., and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

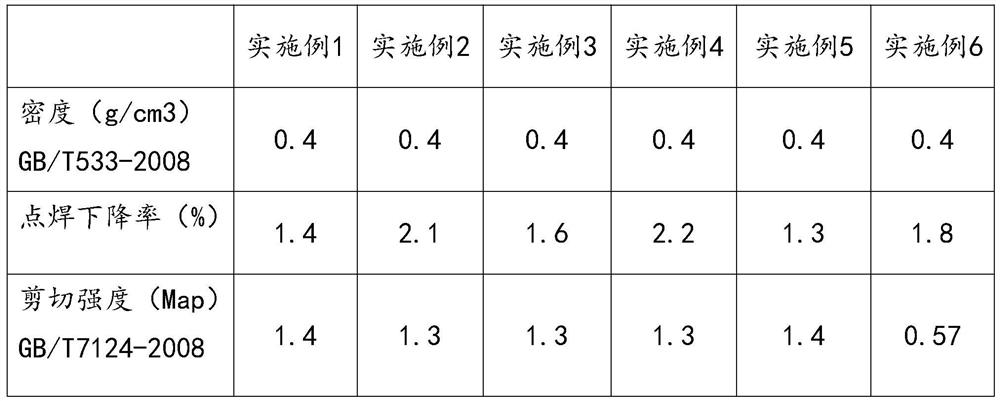

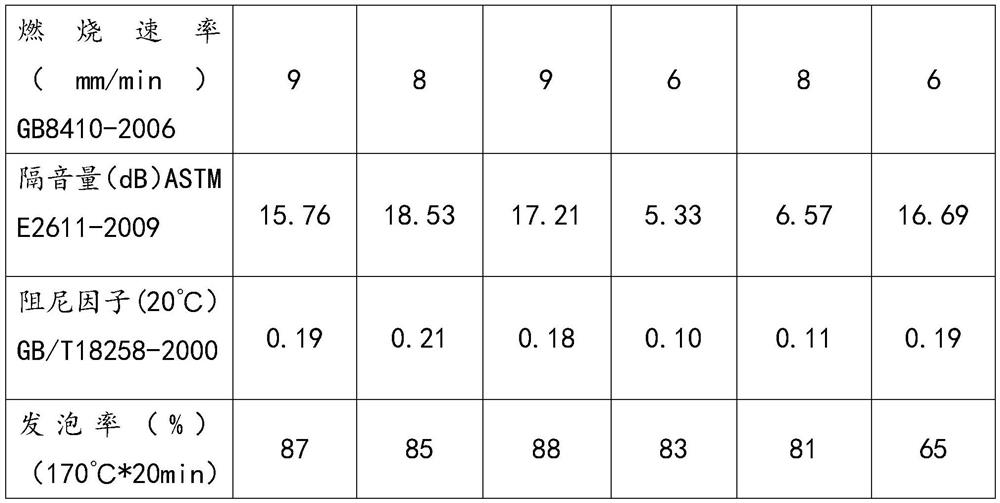

Embodiment 1

[0013] A spot welding sealing foam rubber pad for vehicles, made of the following raw materials in weight ratio: butyl rubber JSR268 23%, paraffin oil 12%, hydrogenated C5 petroleum resin 2.5%, conductive carbon black 8%, aluminum hydroxide 15%, mica powder 20%, vermiculite powder 12%, zinc oxide 1%, stearic acid 0.5%, sulfur 0.8%, accelerator TMTD0.5%, accelerator DM1%, foaming agent AC2.5%, antioxidant RD1.2%. Mix according to the formula amount, carry out compaction in the internal mixer, and then extrude into sheets through a screw extruder, and cut into prescribed shapes.

Embodiment 2

[0015] A spot welding sealing foam rubber pad for vehicles, made of the following raw materials in weight ratio: butyl rubber JSR268 23%, paraffin oil 12%, hydrogenated C5 petroleum resin 2.5%, conductive carbon black 5%, aluminum hydroxide 15%, mica powder 20%, vermiculite powder 15%, zinc oxide 1%, stearic acid 0.5%, sulfur 0.8%, accelerator TMTD0.5%, accelerator DM1%, foaming agent AC2.5%, antioxidant RD1.2%. Mix according to the formula amount, carry out compaction in the internal mixer, and then extrude into sheets through a screw extruder, and cut into prescribed shapes.

Embodiment 3

[0017] A spot welding sealing foam rubber pad for vehicles, made of the following raw materials in weight ratio: butyl rubber JSR268 23%, paraffin oil 12%, hydrogenated C5 petroleum resin 2.5%, conductive carbon black 8%, aluminum hydroxide 15%, mica powder 15%, vermiculite powder 17%, zinc oxide 1%, stearic acid 0.5%, sulfur 0.8%, accelerator TMTD0.5%, accelerator DM1%, foaming agent AC2.5%, antioxidant RD1.2%. Mix according to the formula amount, carry out compaction in the internal mixer, and then extrude into sheets through a screw extruder, and cut into prescribed shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com