High flame retardant super low temperature resistant environmental flexible cable

A technology with low temperature resistance and high flame retardancy, applied in the application field of new materials, can solve problems such as human and environmental hazards, non-environmental protection, flame retardancy, halogen pollution, etc., and achieve the effects of strong torsion resistance, non-aging, and non-cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A highly flame-retardant, ultra-low temperature resistant and environment-friendly soft cable, comprising a stranded soft conductor, an insulator and an outer sheath, the insulating layer covers the outside of the stranded soft conductor to form an insulated single wire, the outer sheath covers at least two insulated single wires, and the insulated The layer is made of the same material as the outer sheath, with EPDM as the dispersed phase and polypropylene as the continuous phase.

[0037] Among them, the insulating layer and the outer protective layer are composed of: EPDM 70 parts, polypropylene 30 parts, paraffin oil 30~40 parts, crosslinking agent 2~6 parts, crosslinking auxiliary agent 1~4, activator 1~ 4 parts, cold-resistant plasticizer 10-20 parts, flame retardant 50-70 parts, accelerator 1-4 parts, filler 5-20 parts.

[0038] Among them, the flame retardant is a non-halogen flame retardant.

[0039] Among them, the non-halogen flame retardant is 10 parts of a...

Embodiment 2

[0052] The high flame-retardant, ultra-low temperature resistant and environment-friendly flexible cable of the present invention has the same main content as that of the above-mentioned embodiment 1, and the difference lies in:

[0053] Through experiments, preferably, the basic composition of the insulating layer and the outer protective layer is: 70 parts of EPDM, 30 parts of polypropylene, 33-38 parts of paraffin oil, 3-5 parts of cross-linking agent, 1-3 parts of cross-linking auxiliary agent 1-3 parts of activator, 13-17 parts of cold-resistant plasticizer, 55-65 parts of flame retardant, 1-3 parts of accelerator, and 8-15 parts of filler.

[0054] The high-flame-retardant, super-low-temperature-resistant and environmentally-friendly flexible cable adopting the above-mentioned technical solution has strong torsion resistance, is not easy to age, and is super-low-temperature-resistant. It can work in a low-temperature environment below -60°C, is not easy to crack, and is f...

Embodiment 3

[0056] The high flame-retardant, ultra-low temperature resistant and environment-friendly flexible cable of the present invention has the same main content as that of the above-mentioned embodiment 1, and the difference lies in:

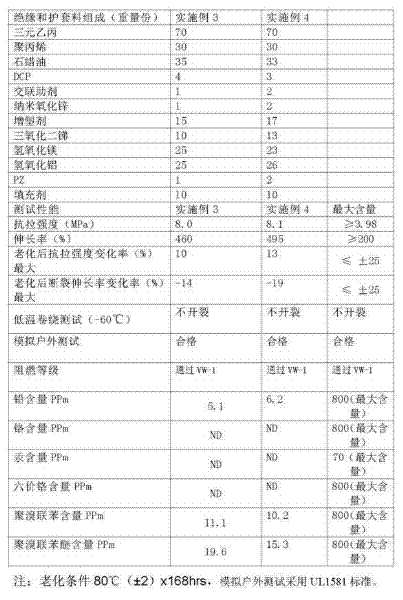

[0057] See Table 1 through experiments. Preferably, the basic composition of the insulating layer and the outer sheath is: 70 parts of EPDM, 30 parts of polypropylene, 35 parts of paraffin oil, 4 parts of cross-linking agent, 1 part of cross-linking auxiliary agent, activation 1 part of plasticizer, 15 parts of cold-resistant plasticizer, 60 parts of flame retardant, 1 part of accelerator, and 10 parts of filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com