Ultraviolet curing liquid optical clear adhesive and preparation method thereof

A technology of ultraviolet light and optical glue, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of late start of UV curing adhesive research, industrialization process to be developed and researched, production scale to be expanded, etc. , to achieve good light transmittance and refractive index, moderate viscosity, good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

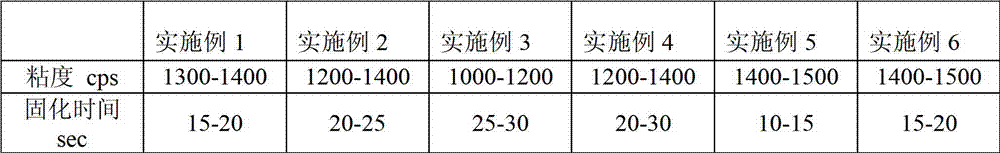

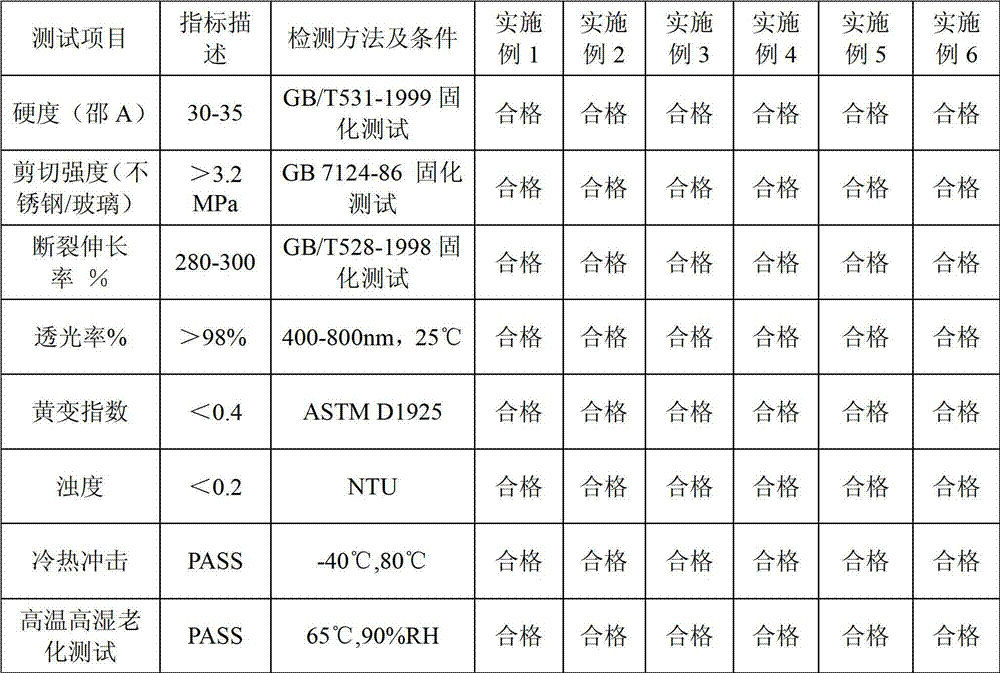

Examples

Embodiment 1

[0028] Step 1, the preparation of urethane acrylate prepolymer: including the following steps: add toluene diisocyanate into a four-necked flask equipped with a stirrer, thermometer, condenser and constant pressure funnel, protect it with nitrogen, and store it at room temperature at 20-25°C 1. Under the condition that the stirring speed is 80-100 rev / min, slowly add polyethylene glycol dropwise from the constant pressure funnel. The mass ratio of the toluene diisocyanate to the polyethylene glycol is 0.95:1. After 3 hours of heat preservation reaction, gradually add 32.5% hydroxyethyl acrylate dropwise for reaction, and add 0.1% polymerization inhibitor at the same time, gradually raise the temperature to 65-70°C after dropping, and react for about 4 hours. When the temperature in the four-neck flask dropped to 50°C, 0.5% by mass of absolute ethanol was added to react for 20 minutes, and suction filtered to obtain the polyurethane acrylate prepolymer (PUA). After the prepare...

Embodiment 2

[0040] Same as Example 1, the difference is:

[0041] The specific operation steps of the step 2 are: add 38% of the urethane acrylate prepolymer prepared in the step 1 into a 5L four-necked flask equipped with a stirrer and a thermometer, and mix the urethane acrylate prepolymer with Free radical reactive diluent 48% is mixed and stirred evenly, and described free radical reactive diluent is hydroxyethyl acrylate, tripropylene glycol diacrylate and trimethylolpropane triacrylate as a mixture of three, adding diphthalic acid diluent Octyl ester 10%, BAPO3%, KH-5700.6%, BYK-1410.3%, 2640.1%, stirred for 1-2h until the dioctyl phthalate, the BAPO, the KH-570, the BYK -141. After the 264 component is completely dissolved, the finished UV-curable liquid optical adhesive can be obtained.

Embodiment 3

[0043] Same as Example 1, the difference is:

[0044] The specific operation steps of the step 2 are: add 45% of the urethane acrylate prepolymer prepared in the step 1 into a 5L four-necked flask equipped with a stirrer and a thermometer, and mix the urethane acrylate prepolymer with 40% of the free radical active diluent was mixed and stirred evenly. The free radical active diluent was a mixture of hydroxyethyl acrylate, tripropylene glycol diacrylate and trimethylolpropane triacrylate. Octyl ester 10%, BAPO4%, KH-5700.6%, BYK-1410.3%, 2640.1%, stirred for 1-2h until the dioctyl phthalate, the BAPO, the KH-570, the BYK -141. After the 264 component is completely dissolved, the finished UV-curable liquid optical adhesive can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com