Method for treating inner surface of microchannel

A micro-channel, inner surface technology, applied in chemical instruments and methods, laboratory containers, instruments, etc., can solve the problems of wrong detection results, sample residues, transportation, etc., to reduce residues and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

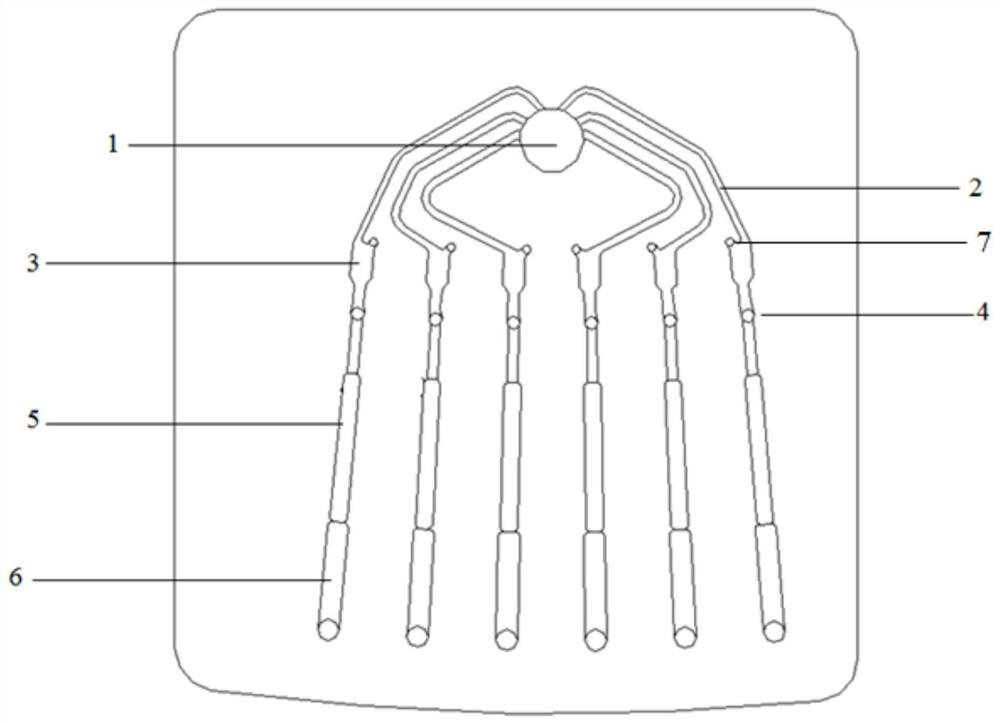

[0031] The microfluidic chip used in this example is as figure 1 shown. It includes a sample inlet 1 , a plurality of liquid separation channels 2 , a quantitative zone 3 , a stop valve 4 , a reaction zone 5 , a detection zone 6 and a gas hole 7 . The injection port 1 is used for sample loading, with a diameter of 3 mm. The dispensing channel 2 is used to deliver the sample to its respective downstream chambers, with an inner diameter of 0.1 mm. The quantitative area 3 is used to control the amount of sample entering each reaction area 5, and the total volume is 3 μL. The stop valve 4 is used to prevent the sample from entering the reaction zone 5 before centrifugation or before reaching a certain centrifugation speed. The reaction zone 5 is the zone where the sample reacts with the detection reagent, and the separation zone 6 can be used to observe the reaction result. The air hole 7 is used to eliminate the gas pressure generated by the liquid entering the dosing zone 3 ...

Embodiment 2

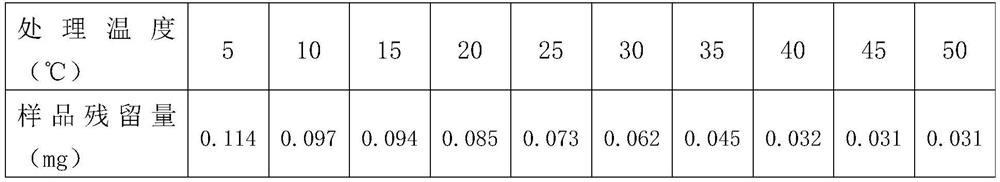

[0041] Using the same microfluidic chip as in Example 1 and a similar paraffin oil treatment method, the effect of temperature on sample residue was studied. The test process is as follows:

[0042] 1) Take 30 chips, 3 chips in each group, add 5 μL of paraffin oil into the injection port, fill the liquid separation channel and quantitative area, and place them for 5 hours under 10 different temperature conditions;

[0043] 2) Place absorbent paper with a diameter of 3 mm on the sample inlet, and reverse centrifugation at 200g for 3 min to suck out excess paraffin oil, repeat three times, and replace the absorbent paper each time;

[0044] 3) Weigh the processed microfluidic chip, record the weight, add 3 mg of whole blood sample from the injection port, place 3mm diameter absorbent paper on the injection port after filling the quantitative area and liquid separation channel, and reverse centrifuge at 200g After 3 minutes, the sample was fully sucked out, and then the microflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com