A sucker rod anti-spray self-sealing wax scraping guide device

A technology of a diversion device and a sucker rod is applied in the directions of wellbore/well components, earthwork drilling, cleaning tools, etc., to achieve the effects of convenient use, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

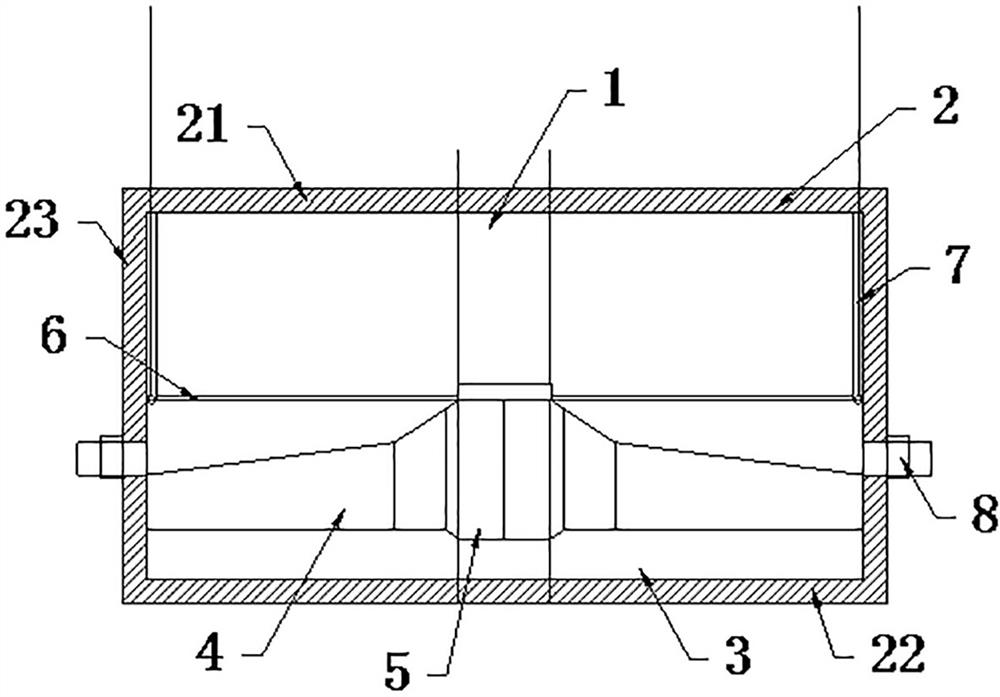

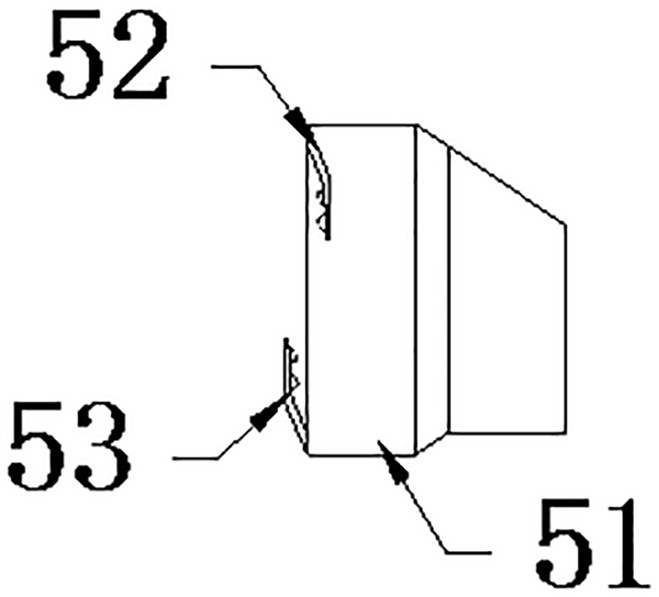

[0034] see Figure 1-3 , a sucker rod anti-blowout self-sealing wax scraping guide device provided by the present invention, comprising a sucker rod 1, a housing 2, a wax scraper 5, and a guide pipe 8, and the housing 2 includes an upper cover plate 21 , the lower cover plate 22 and the side wall 23, the lower cover plate 22 is arranged on the lower part of the housing 2, the upper cover plate 21 is screwed to the upper part of the housing 2, and the sucker rod 1 passes through the lower part of the housing 2 Center, the wax scraper 5 is installed in the shell 2, and set on the sucker rod 1;

[0035] Both sides of the wax scraper 5 are provided with a circular deflector 4, and at least one deflector 8 is provided on the side wall 23 of the housing 2, and the outer end of the deflector 4 is connected to the deflector 8. ;

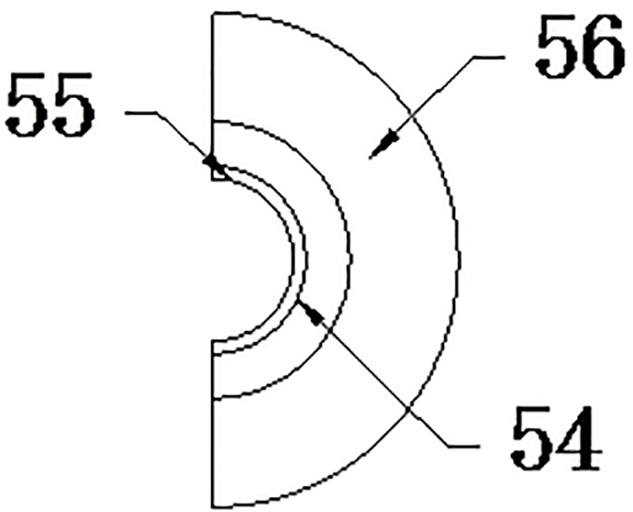

[0036] A filter plate 6 is arranged above the deflector 4, and a sleeve is provided at the center of the filter plate 6, and the sleeve is installed on th...

Embodiment 2

[0056] see Figure 1-3 , a sucker rod anti-blowout self-sealing wax scraping guide device provided by the present invention, comprising a sucker rod 1, a housing 2, a wax scraper 5, and a guide pipe 8, and the housing 2 includes an upper cover plate 21 , the lower cover plate 22 and the side wall 23, the lower cover plate 22 is arranged on the lower part of the housing 2, the upper cover plate 21 is screwed to the upper part of the housing 2, and the sucker rod 1 passes through the lower part of the housing 2 Center, the wax scraper 5 is installed in the shell 2, and set on the sucker rod 1;

[0057] Both sides of the wax scraper 5 are provided with a circular deflector 4, and at least one deflector 8 is provided on the side wall 23 of the housing 2, and the outer end of the deflector 4 is connected to the deflector 8. ;

[0058] A filter plate 6 is arranged above the deflector 4, and a sleeve is provided at the center of the filter plate 6, and the sleeve is installed on th...

experiment example

[0078] Experimental objects: use ordinary commercially available filter plates as control group 1, use imported filter plates as control group 2, and use the filter plates of this application as the experimental group.

[0079] Experimental requirements: The shape, thickness, and volume of the three sets of filter plates are all the same, and the corrosion resistance test and ball pressure test are carried out respectively, and the following data are obtained.

[0080] The specific results are shown in the table below:

[0081]

[0082] Combining the above table, comparing the data obtained by three different experimental objects under three different experimental methods, the corrosion resistance and hardness of the filter plate of the present invention are better than those of the two control groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com