Dedicated oil adjusting paraffin removal device for rodless oil production and device with paraffin removal device

A rodless oil recovery and oil adjustment technology, which is applied in isolation devices, cleaning equipment, earthwork drilling and production, etc., can solve problems affecting oil recovery efficiency, affecting oil recovery efficiency, oil well shutdown and maintenance, etc., achieves excellent dimensional stability, improves collection Effect of skin effect, good thermal conductivity and insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

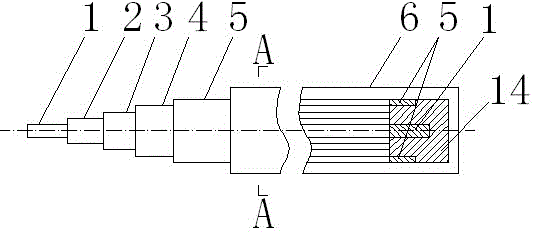

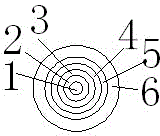

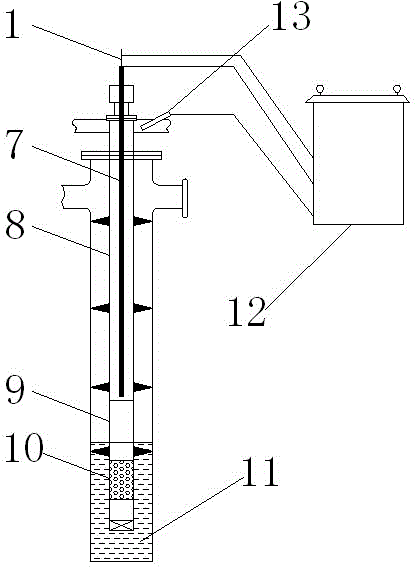

[0017] The invention is described in further detail in conjunction with accompanying drawings, as figure 1 , 2 As shown in the figure, the oil-adjusting and wax-removing device for rodless oil production includes copper wire 1, and its structure from inside to outside is copper wire 1, polyimide film 2, fluoroplastic 3, glass fiber cloth 4, and stainless steel heating tube. 5. Insulated and heat-conducting sheath 6; the right end of the copper wire 1 and the right end of the stainless steel heating pipe 6 are electrically connected together by welding to form an electrical connection 14, and the right end of the electrical connection 14 is provided with an insulating and heat-conducting sheath 6. That is to say, copper conductor 1 is provided with 2 layers of polyimide film, 2 layers of polyimide film are provided with 3 layers of fluoroplastic, fluorine plastic 3 is provided with 4 layers of glass fiber cloth, and glass fiber cloth 4 is covered with There are 5 layers of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com