A device and method for microfluidic transport on a piezoelectric substrate

A piezoelectric substrate, microfluidic technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of decreased biomolecular activity and increased temperature of microfluidics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

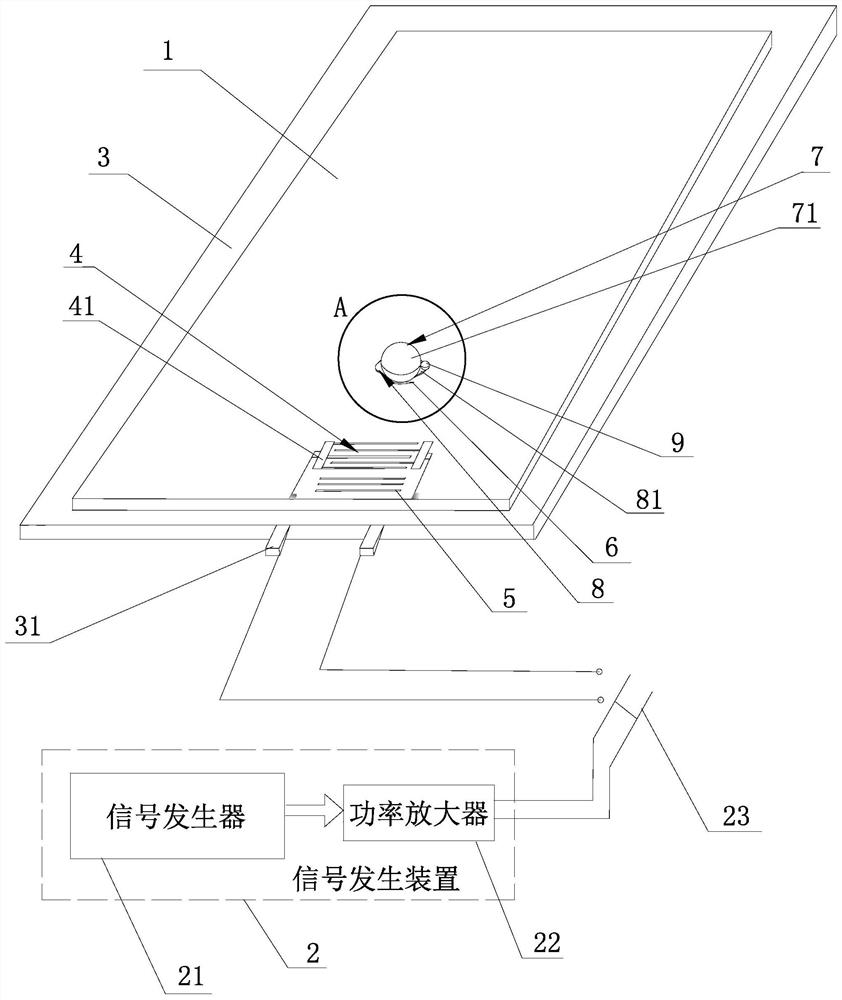

[0023] A device for transporting microfluids on a piezoelectric substrate proposed in this embodiment includes a piezoelectric substrate 1, a signal generating device 2 for generating RF electrical signals, a PCB board 3, and the upper surface of the piezoelectric substrate 1 As the working surface, an unweighted interdigital transducer 4 for exciting surface acoustic waves is arranged on the periphery of the working surface of the piezoelectric substrate 1, and the unweighted interdigital transducer 4 is arranged on the working surface of the piezoelectric substrate 1 with the unweighted interdigital transducer 4. Correspondingly, the transducer 4 is provided with a reflection grid 5, the reflection grid 5 is used to reduce the power of the RF electrical signal loaded on the unweighted interdigital transducer 4, and the working surface of the piezoelectric substrate 1 is located on the unweighted interdigital transducer 4. On the propagation path of the surface acoustic wave e...

Embodiment 2

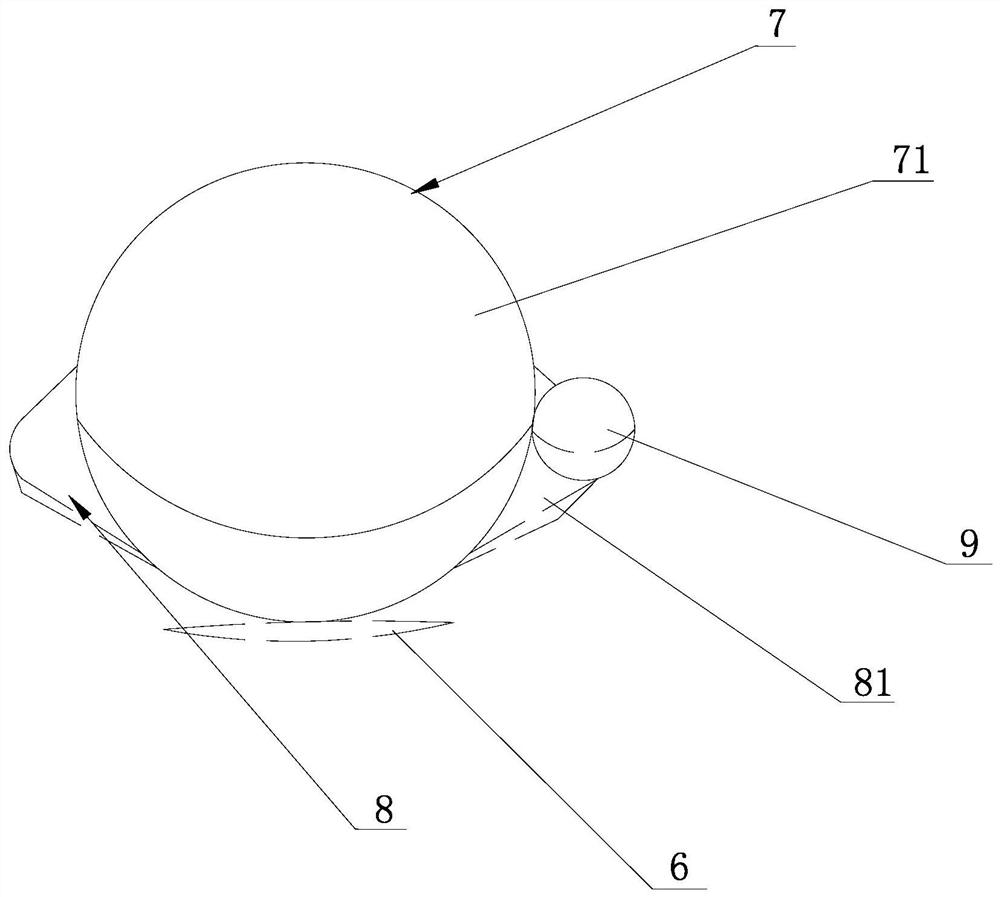

[0025] The device for transporting microfluids on a piezoelectric substrate proposed in this embodiment is further improved on the basis of the device in Embodiment 1, that is, PDMS coagulation layers are arranged on both sides of the symmetrical surface of the middle part of the microsphere bead 7. Layer 8, the PDMS coagulation layer 8 protrudes from the surface of the microsphere beads 7 by 0.2 mm to 0.5 mm (such as 0.4 mm), and the width of the PDMS coagulation layer 8 along the circumference of the microsphere beads 7 is 0.2 mm to 0.5 mm (such as 0.5 mm). ), the upper surface of the PDMS solidified layer 8 is used as the second liquid storage area 81 for storing the aqueous microfluid 9 to be transported. The PDMS coagulation layer 8 is arranged on both sides of the symmetrical surface of the middle part of the microsphere bead 7, which can ensure that the microsphere bead 7 is stressed symmetrically; The second liquid storage area 81, that is, under the premise of setting...

Embodiment 3

[0027] A device for transporting microfluids on a piezoelectric substrate proposed in this embodiment is basically the same in structure as that of the device in Embodiment 1 or Embodiment 2, the only difference being that the device of this embodiment is in the piezoelectric substrate 1 Unweighted interdigital transducers 4 are arranged at different positions around the working surface of the working surface, that is, a plurality of unweighted interdigital transducers 4 are arranged, and the unweighted interdigital transducers 4 at different positions are configured by a switching switch 23 4 is loaded with an RF electric signal, and the aqueous solution microfluid 9 to be transported stored on the first liquid storage area 71 or the second liquid storage area 81 can be transported at any position in the two-dimensional plane of the working surface of the piezoelectric substrate 1. transport.

[0028] As mentioned above, the piezoelectric substrate 1 can adopt a piezoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com