A sealing device for well-type furnace mouth

A sealing device and sealing ring technology, used in the sealing of engines, vertical furnaces, furnaces, etc., can solve the problems of furnace gas leakage and poor sealing of pit furnaces, so as to enhance the sealing effect, improve reliability and safety Sex, solve the effect of small contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

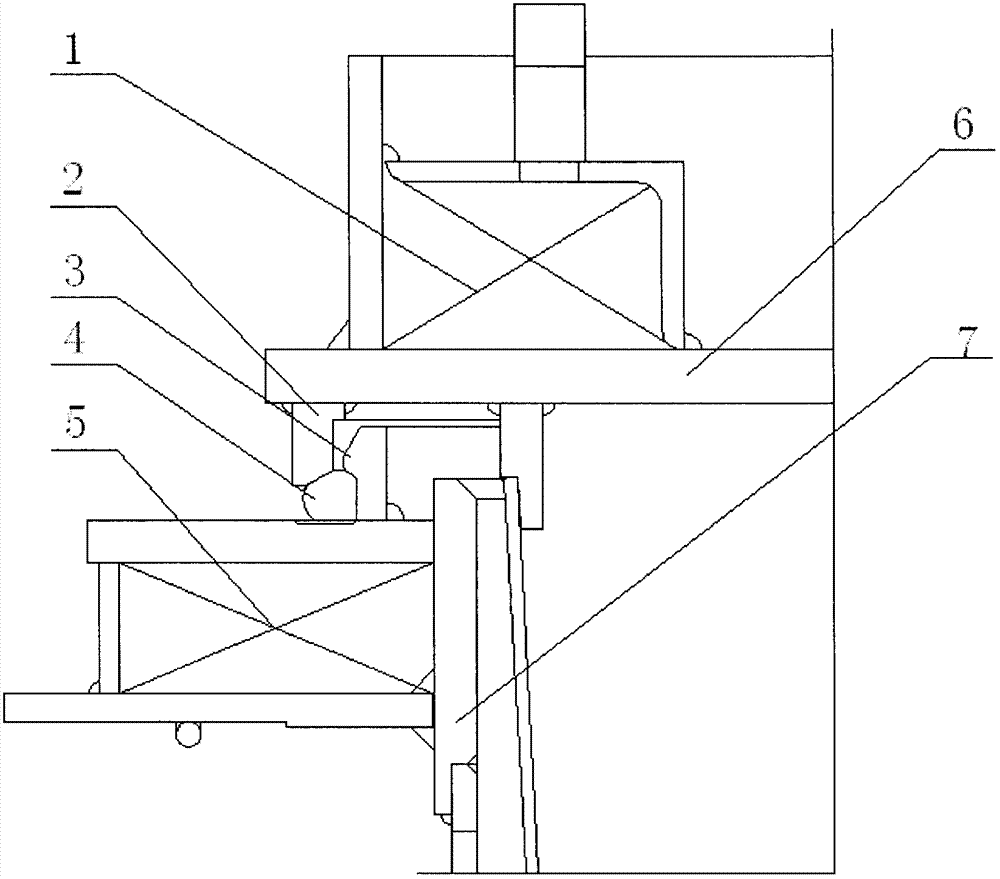

[0015] Such as figure 1 As shown, a sealing device for a well-type furnace mouth includes: a furnace cover cooling chamber 1, a furnace cover sealing ring 2, a muffle guide groove 3, a sealing ring 4, a muffle cooling chamber 5, a furnace cover 6 and a muffle Furnace body 7, the furnace cover cooling cavity 1 is fixed on the top surface of the furnace cover 6; the furnace cover sealing ring 2 is fixed on the edge of the bottom surface of the furnace cover 6; the muffle cooling cavity 5 is fixed on the top of the muffle furnace body 7 Outside: the muffle guide groove 3 is fixed on the top surface of the muffle cooling cavity 5; the sealing ring 4 is fixed between the furnace cover sealing ring 2 and the muffle guide groove 3 .

[0016] During operation, the furnace cover cooling chamber 1 and the muffle cooling chamber 5 are cooled in the upper and lower spaces to protect the silicone rubber sealing ring 4 from high temperature aging and prolong its service life. The furnace co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com