Emulsion paraffin remover for oil well as well as preparation method and application thereof

A technology of wax remover and emulsion, which is applied in the field of oil well emulsion wax remover and its preparation, can solve the problem of less wax remover products, and achieve the effect of effectively reducing viscosity by surface tension and remarkable effect of wax removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

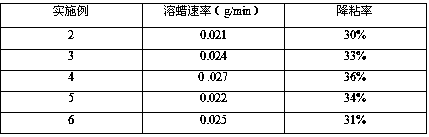

Examples

Embodiment 1

[0022] This embodiment provides an emulsion wax remover for oil wells, comprising the following components in parts by weight: 25-45 parts of diesel oil, 3-6 parts of gemini quaternary ammonium salt, 3-7 parts of fatty alcohol polyoxyethylene ether, lost 1.5-2.5 parts of sorbitan oleate, 2-5 parts of mutual solvent, 1-3 parts of sodium hydroxide, 35-60 parts of water.

[0023] The principle of the invention: Gemini quaternary ammonium salt, fatty alcohol polyoxyethylene ether, and sorbitan oleate three surfactants can play the role of wetting reversal, so that the surface of the wax deposition is reversed from the lipophilic surface to the hydrophilic surface. The water surface is conducive to the shedding of wax; the penetration of these substances can weaken the cohesion between the wax molecules and the pipe wall, so that it can be easily removed from the pipe wall, and the three surfactants play a synergistic effect to produce The effect of extremely low surface tension en...

Embodiment 2

[0026] On the basis of Example 1, this example provides an emulsion wax remover for oil wells, comprising the following components in parts by weight: 30 parts of diesel oil, 3 parts of Gemini quaternary ammonium salt, 5 parts of fatty alcohol polyoxyethylene ether , 1.5 parts of sorbitan oleate, 2 parts of mutual solvent, 1.5 parts of sodium hydroxide, and 57 parts of water.

[0027] Preparation process: Step 1) sequentially add the formula quantity of Gemini quaternary ammonium salt, fatty alcohol polyoxyethylene ether, and sorbitan oleate into the formula quantity of water, and stir evenly to obtain the mixture A;

[0028] Step 2) Add the formulated amount of mutual solvent and sodium hydroxide to the mixture A in sequence, and stir evenly to obtain the mixture B;

[0029] Step 3) Add the formulated amount of diesel oil into the mixture B and stir well to obtain the emulsion wax remover.

[0030] In this example, the diesel is 35 # For diesel oil, the gemini quaternary am...

Embodiment 3

[0032] On the basis of Example 1, this example provides an emulsion wax remover for oil wells, comprising the following components in parts by weight: 35 parts of diesel oil, 4 parts of Gemini quaternary ammonium salt, 4.5 parts of fatty alcohol polyoxyethylene ether , 2 parts of sorbitan oleate, 3 parts of mutual solvent, 2 parts of sodium hydroxide, 49.5 parts of water.

[0033] Preparation process: Step 1) sequentially add the formula quantity of Gemini quaternary ammonium salt, fatty alcohol polyoxyethylene ether, and sorbitan oleate into the formula quantity of water, and stir evenly to obtain the mixture A;

[0034] Step 2) Add the formulated amount of mutual solvent and sodium hydroxide to the mixture A in sequence, and stir evenly to obtain the mixture B;

[0035] Step 3) Add the formulated amount of diesel oil into the mixture B and stir well to obtain the emulsion wax remover.

[0036] In this example, the diesel is 35 # Diesel oil, the gemini quaternary ammonium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com