Environment-friendly type wax removal agent and preparation method thereof

A wax remover and environmental protection technology, applied in the field of environmental protection wax remover and its preparation, can solve problems such as adverse effects on the environment, and achieve the effects of fast wax removal, enhanced decontamination effect, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

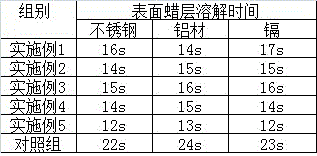

Examples

Embodiment 1

[0022] An environmentally friendly wax remover, prepared from the following raw materials in parts by weight: 40 parts of polyacrylamide, 16 parts of fatty alcohol polyoxyethylene ether, 10 parts of sodium citrate, 12 parts of coconut oleic acid diethanolamide, 14 parts of ethanol 15 parts of calcium carbonate, 8 parts of salicylic acid, 3 parts of glycerin laurate, 6 parts of saponin extract, 4 parts of clove extract, 2 parts of penetrant, and 1 part of defoamer.

[0023] The preparation method of described environmental protection dewaxing agent, comprises the following steps:

[0024] 1) Put the polyacryloyl and fatty alcohol polyoxyethylene ether in the formula amount in a blender, the speed of the blender is 600r / min, mix and stir for 20 minutes, add the same weight of water, stir again for 30 minutes, and get the mixture for later use;

[0025] 2) Grind the calcium carbonate in the prescribed amount into powder, pass through a 600-mesh sieve, add ethanol to mix and stir,...

Embodiment 2

[0029] An environmentally friendly wax remover, prepared from the following raw materials in parts by weight: 52 parts of polyacrylamide, 28 parts of fatty alcohol polyoxyethylene ether, 16 parts of sodium citrate, 18 parts of coconut oleic acid diethanolamide, 20 parts of ethanol 21 parts of calcium carbonate, 14 parts of salicylic acid, 9 parts of glycerin laurate, 12 parts of saponin extract, 10 parts of clove extract, 8 parts of penetrant, and 7 parts of defoamer.

[0030] The preparation method of described environmental protection dewaxing agent, comprises the following steps:

[0031] 1) Put the polyacryloyl and fatty alcohol polyoxyethylene ether in the formula amount in a blender, the speed of the blender is 800r / min, mix and stir for 30 minutes, add the same weight of water, stir again for 40 minutes, and get the mixture for later use;

[0032] 2) Grind the calcium carbonate in the prescribed amount into powder, pass through a 600-mesh sieve, add ethanol to mix and s...

Embodiment 3

[0036] An environmentally friendly wax remover, prepared from the following raw materials in parts by weight: 44 parts of polyacrylamide, 20 parts of fatty alcohol polyoxyethylene ether, 12 parts of sodium citrate, 14 parts of coconut oleic acid diethanolamide, 16 parts of ethanol 17 parts of calcium carbonate, 10 parts of salicylic acid, 5 parts of glycerin laurate, 8 parts of saponin extract, 6 parts of clove extract, 4 parts of penetrant, and 3 parts of defoamer.

[0037] The preparation method of described environmental protection dewaxing agent, comprises the following steps:

[0038] 1) Put the polyacryloyl and fatty alcohol polyoxyethylene ether in the formula amount in a blender, the speed of the blender is 600r / min, mix and stir for 20 minutes, add the same weight of water, stir again for 30 minutes, and get the mixture for later use;

[0039] 2) Grind the calcium carbonate in the prescribed amount into powder, pass through a 600-mesh sieve, add ethanol to mix and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com