Wax clearing agent, preparation method and applications thereof

A technology of wax remover and pour point depressant, which is applied in the field of wax remover and its preparation, can solve the problem that ultra-deep condensate gas wells are difficult to remove blockage, etc., achieve excellent biodegradability and low temperature performance, simple composition, good wax removal effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

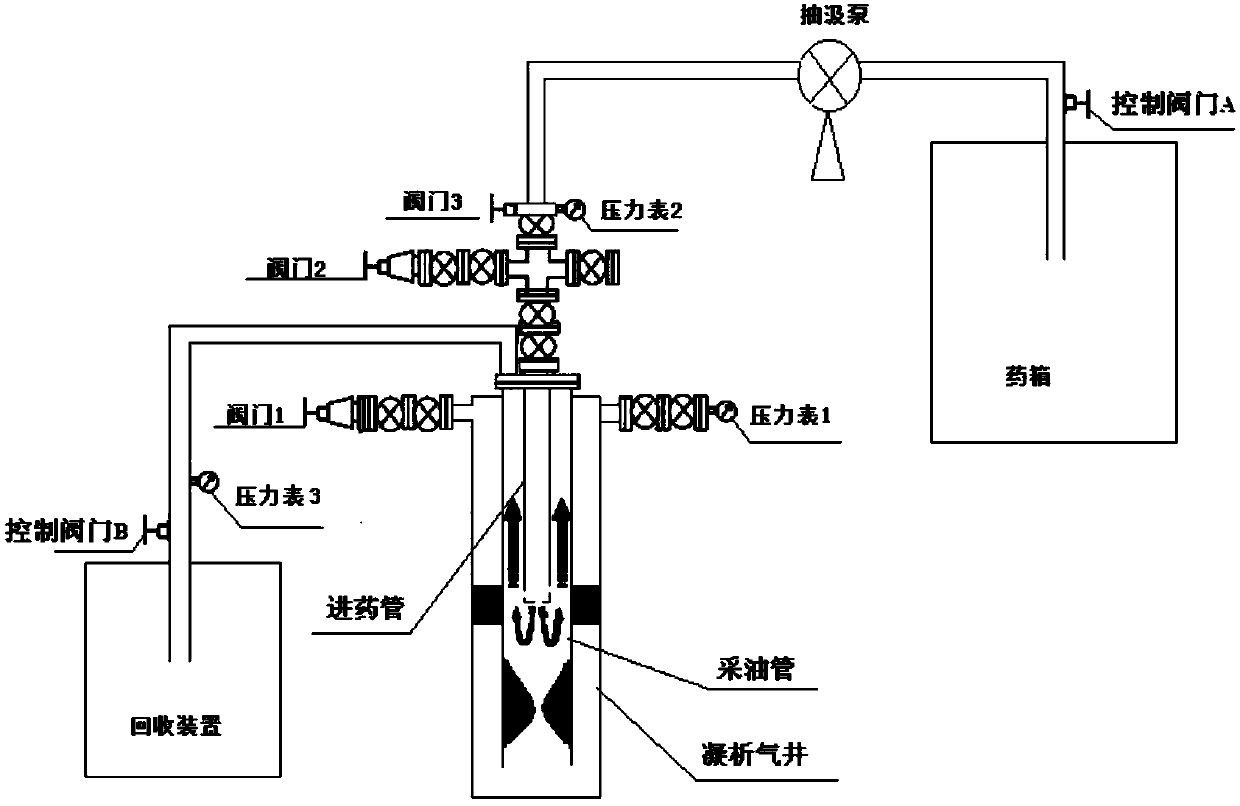

Image

Examples

Embodiment 1

[0071] The wax remover of the present embodiment comprises the following components according to weight percentage:

[0072] Ethylene-vinyl acetate copolymer: 1.55%

[0073] Dichloroethane: 1.5%

[0074] Polyacrylate: 0.65%

[0075] Styrene: 1.5%

[0076] Dispersant: 0.3%

[0077] Penetrant: 0.2%

[0078] Pour point depressant: 0.55%

[0079] C9 aromatics: 93.75%.

[0080] The wax remover can be prepared as follows:

[0081] After batching according to the above composition, the ethylene-vinyl acetate copolymer, ethylene dichloride, polyacrylate, styrene, dispersant, penetrant, pour point depressant and carbon nine are mixed in the reactor, heated to 60 °C, stirred at a stirring speed of 250r / min for 2h, cooled to room temperature, and prepared the wax remover of this example.

Embodiment 2

[0083] The wax remover of the present embodiment comprises the following components according to weight percentage:

[0084] Ethylene-vinyl acetate copolymer: 1.5%

[0085] Dichloroethane: 1.5%

[0086] Polyacrylate: 0.6%

[0087] Styrene: 1%

[0088] Dispersant: 0.2%

[0089] Penetrant: 0.2%:

[0090] Pour point depressant: 0.15%

[0091] C9 aromatics: 94.85%

[0092] The wax remover can be prepared as follows:

[0093] After batching according to the above composition, the ethylene-vinyl acetate copolymer, ethylene dichloride, polyacrylate, styrene, dispersant, penetrant, pour point depressant and carbon nine are mixed in the reactor, heated to 50 °C, stirred at a stirring speed of 270r / min for 3h, cooled to room temperature, and prepared the wax remover of this example.

Embodiment 3

[0095] The wax remover of the present embodiment comprises the following components according to weight percentage:

[0096] Ethylene-vinyl acetate copolymer: 2%

[0097]Dichloroethane: 1.6%

[0098] Polyacrylate: 0.7%

[0099] Styrene: 1.5%

[0100] Dispersant: 0.3%

[0101] Penetrant: 0.25%

[0102] Pour point depressant: 0.17%

[0103] C9 aromatics: 93.47%

[0104] The wax remover can be prepared as follows:

[0105] After batching according to the above composition, the ethylene-vinyl acetate copolymer, ethylene dichloride, polyacrylate, styrene, dispersant, penetrant, pour point depressant and carbon nine were mixed in the reactor, and heated to 74 °C, stirred at a stirring speed of 230r / min for 4h, cooled to room temperature, and prepared the wax remover of this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com