Oil well chemical paraffin remover, preparation method and application thereof and oil well paraffin removal method

A wax remover and oil well technology, which is applied in the fields of oil well wax remover and oil well chemical wax remover, and can solve problems such as potential safety hazards in oil-based wax remover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] [1] Li Jinshuang. Preparation of Petroleum Carboxylate [D]. Daqing Petroleum Institute, 2007.;

[0074] [2] Fu Xiaotai, Yang Youzhen. Analysis of Petroleum Carboxylate Surfactant Solution System [J]. Chemistry and Adhesion, 1995(1): 22-2.

[0075] [3] Wu Yihui, Huang Hongdu, Wang Youfu, etc. Determination of petroleum carboxylate and sulfonate content in mixed solution [J], Oilfield Chemistry, 2000, 17(3):281-284.

[0076] [4] Zou Xinfang, Kong Yan, Gong Jihai, etc. Detection method of carboxylate surfactant in ASP flooding production fluid [J]. Daqing Petroleum Geology and Development, 2003, 22(2):58-60.

[0077] Determination method of wax prevention rate and viscosity reduction rate: according to the standard of "SY / T 6300-2009 Technical Conditions of Clearing and Wax Resistant Agents for Oil Recovery".

Embodiment 1

[0082] The temperature of the oil well is relatively high, and sodium persulfate is used without adding a catalyst.

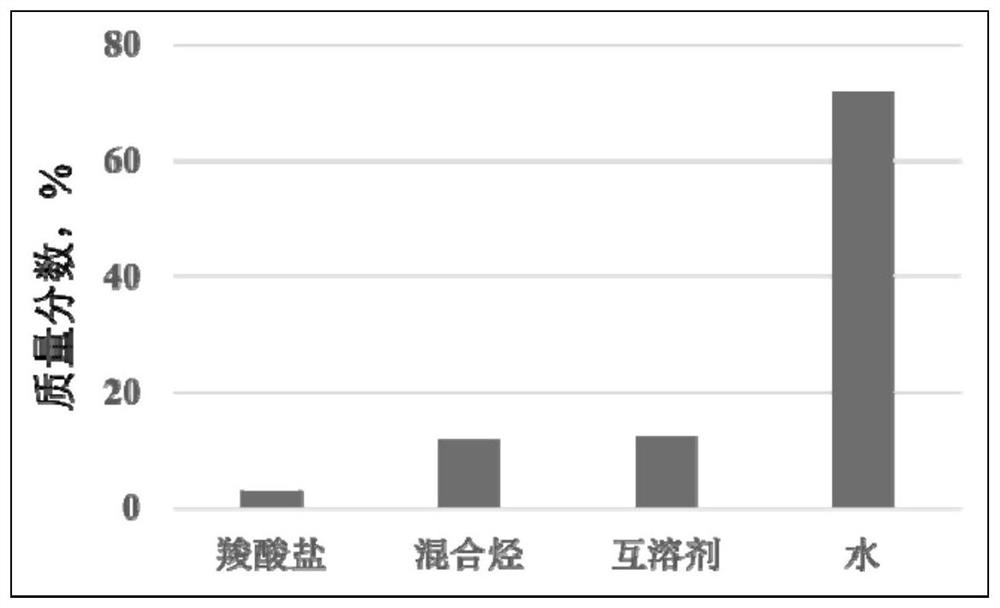

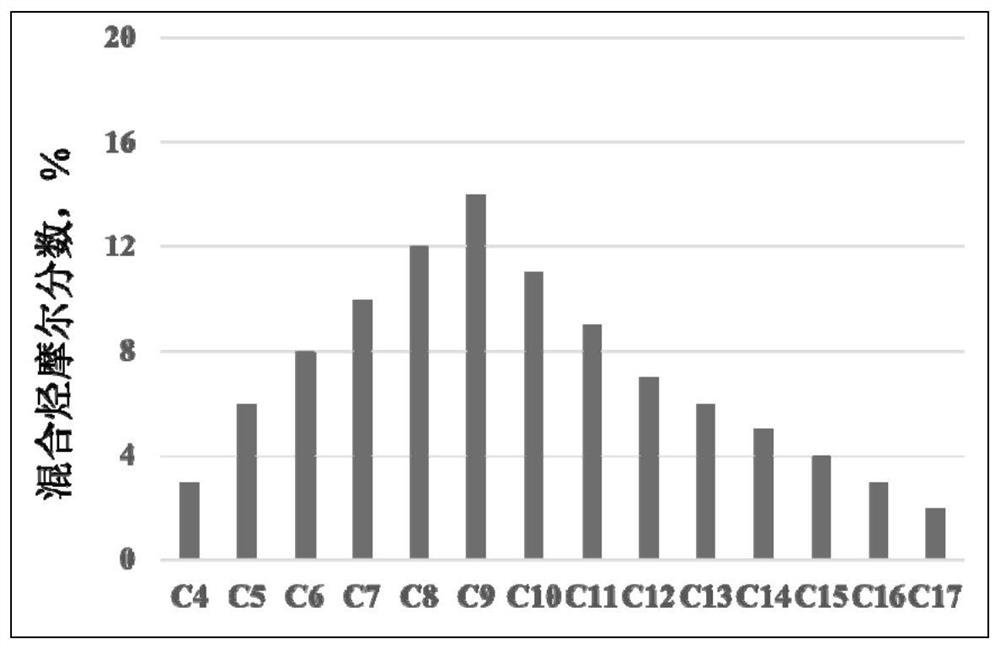

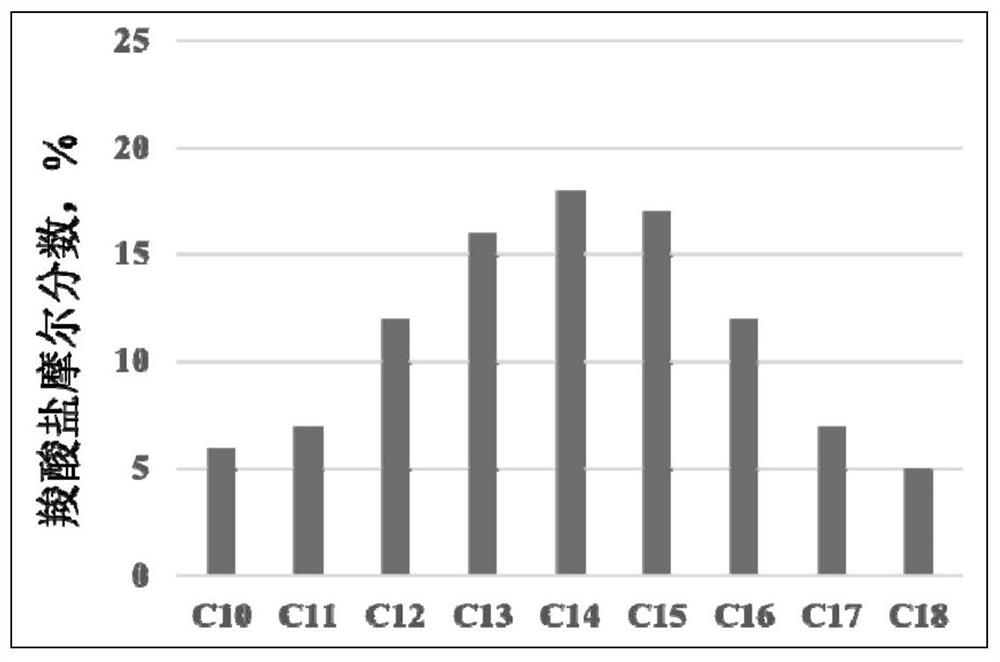

[0083] Preparation of wax remover: put 10g of crude oil into the reactor, add 20g of water, start heating and stirring, set the reaction temperature to 80°C, add 5g of sodium persulfate, react for 2 hours, adjust the pH value of the reaction solution to 10, and get Contain carboxylate surfactant solution (the content of carboxylate surfactant is determined by the method of step titration), then add 5g ethylene glycol monobutyl ether to prepare wax remover; and according to SY / T 6300- 2009 method to determine the wax removal rate and viscosity reduction rate of the wax remover on crude oil samples, the test results are shown in Table 2.

Embodiment 2

[0085] Oil well temperature is low, use sodium persulfate, add catalyst.

[0086] Preparation of wax remover: Put 10g of crude oil into the reactor, add 20g of water, turn on heating and stirring, set the reaction temperature to 40°C, add 5g of sodium persulfate, add 1g of ferrous sulfate, and react for 2 hours, adjust the reaction liquid The pH value is 10, obtains containing carboxylate surfactant solution (the method adopting stepwise titration to measure the content of carboxylate surfactant), then adds 5g Virahol, and measures according to SY / T 6300-2009 method See Table 2 for the test results of the paraffin removal rate and viscosity reduction rate of the crude oil sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com