Device for removing paraffin and washing well by gas heat carrier

A gas heat carrier and wax removal technology, which is used in isolation devices, cleaning appliances, wellbore/well components, etc., can solve the problems of difficult wax and scale cleaning, large emission pollution, low efficiency, etc., and achieves convenient fuel sources. , the effect of improving oil recovery and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

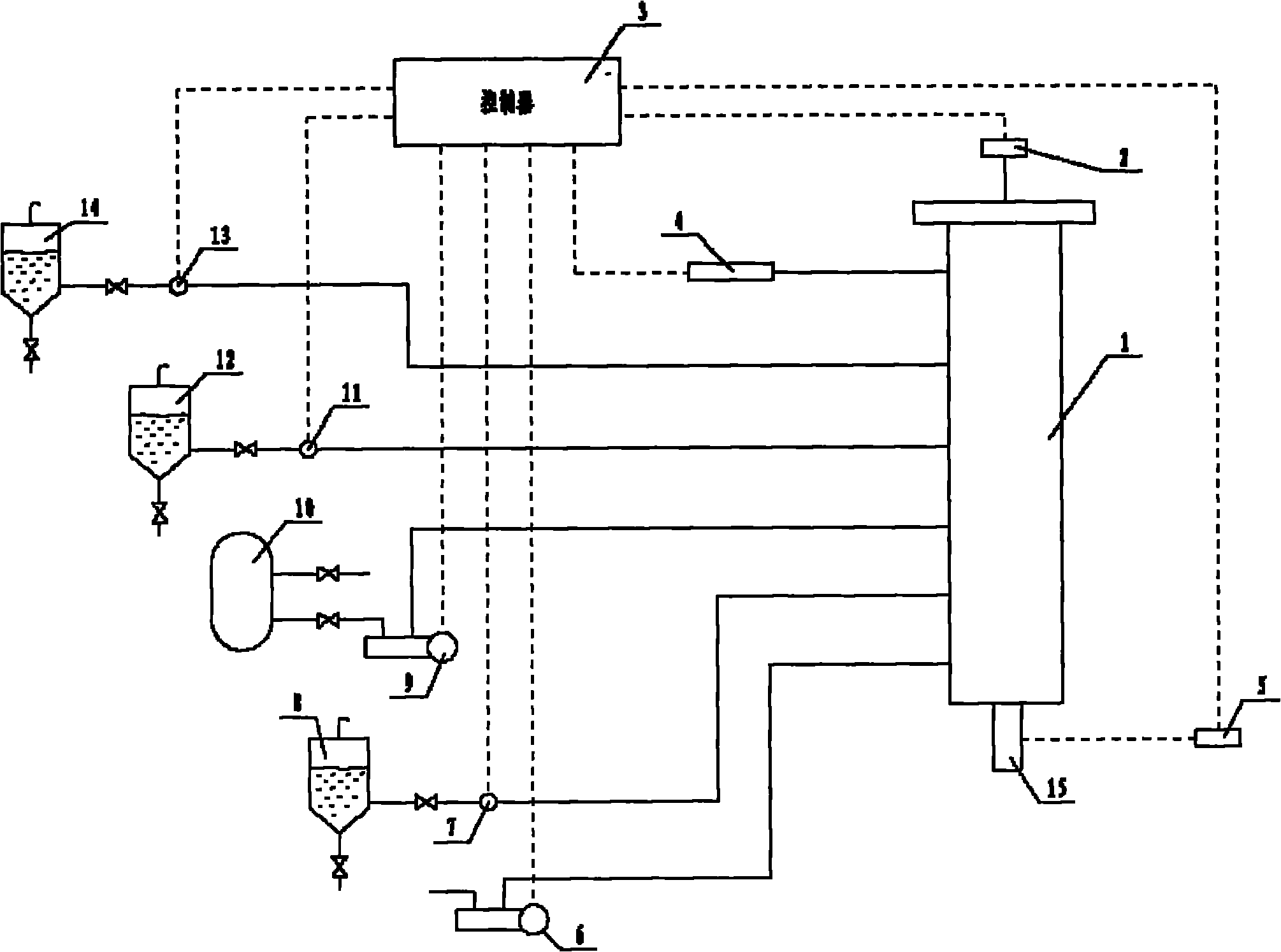

[0028] example 1: figure 1 Schematic diagram of wax removal and well cleaning device for gas heat carrier, including high temperature gas generator 1, igniter 2, controller 3, protection system 4, gas analysis system 5, air compressor 6, high pressure fuel injection pump 7, fuel tank 8, natural gas Compressor 9, natural gas storage tank 10, gasification water injection pump 11, gasification water tank 12, cooling water pump 13, cooling water tank 14, high temperature gas discharge port 15. Because most oil production wells have associated natural gas and its collection system, this device is designed with two sets of fuel systems, fuel oil and gas.

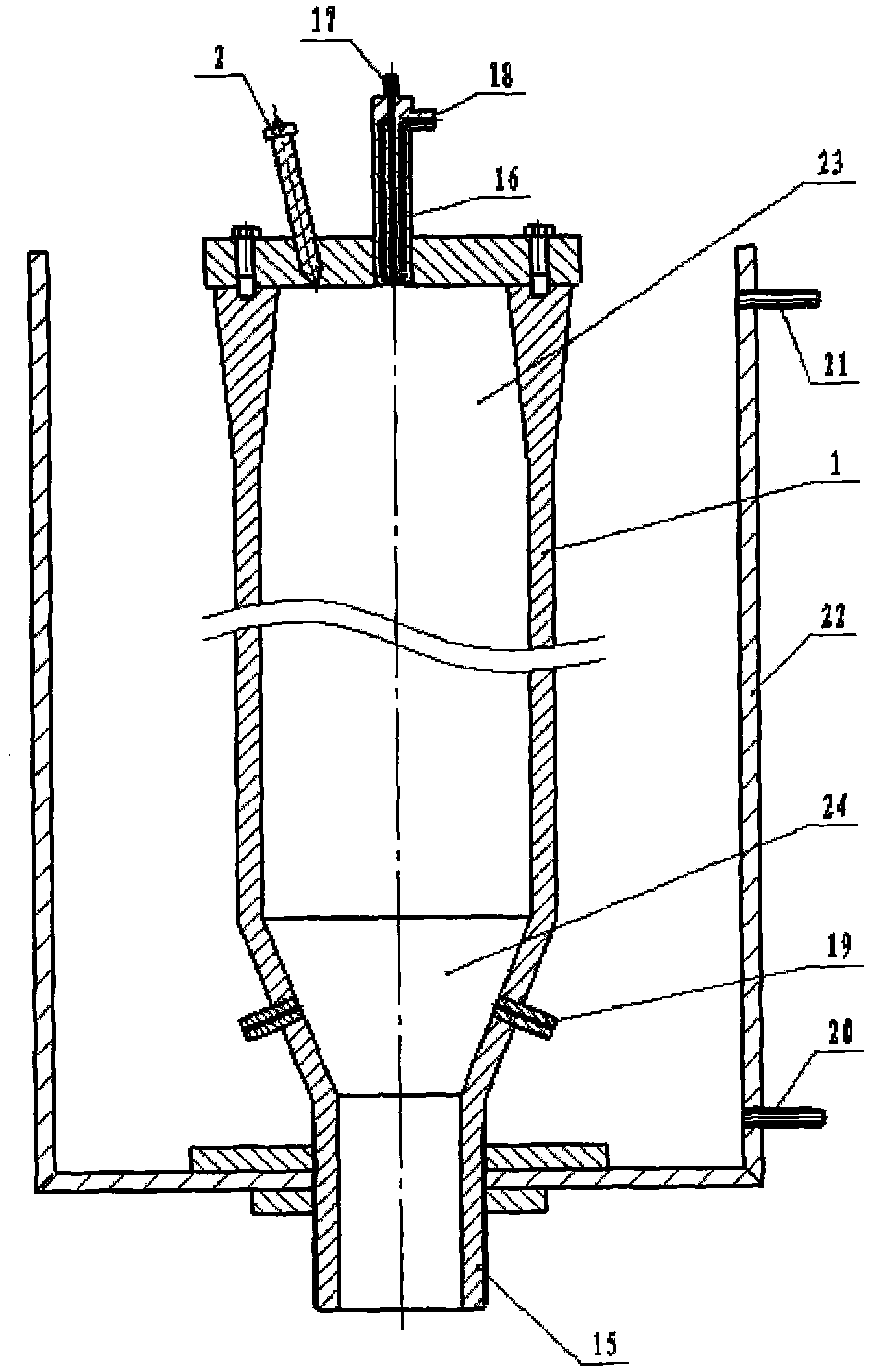

[0029] figure 2 It is a high-temperature gas generator, including gas generator body 1, igniter 2, air-fuel mixer 16, cooling water tank 22, cooling water inlet 21, cooling water outlet 20, combustion chamber 23, gasification chamber 24, gasification water spray Hole 19, gas nozzle 15. The high-temperature gas generator adopts...

example 2

[0032] Example 2 is basically the same as Example 1

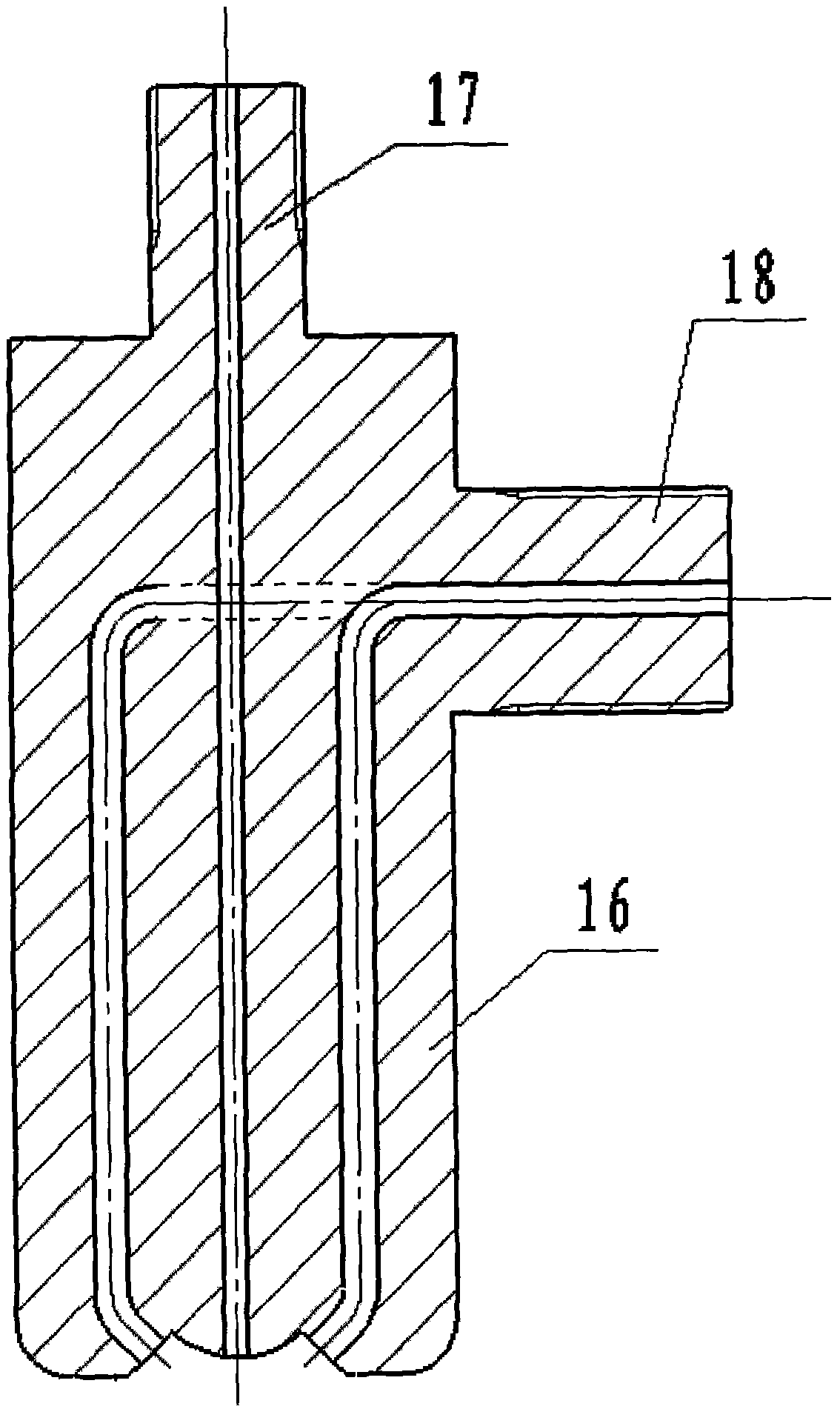

[0033] Description of gas heat carrier wax removal and well washing device: gas heat carrier wax removal and well washing device, including high temperature gas generator 1, igniter 2, controller 3, protection system 4, gas analysis system 5, air compressor 6, high pressure jet Oil pump 7, fuel tank 8, natural gas compressor 9, natural gas storage tank 10, gasification water injection pump 11, gasification water tank 12, cooling water pump 13, cooling water tank 14, high temperature gas discharge port 15, cooling water tank 22, cooling water inlet 21. Cooling water outlet 20 , combustion chamber 23 , gasification chamber 24 , gasification water spray hole 19 , air-fuel mixer 16 including compressed air inlet 18 and fuel inlet 17 . The air-fuel mixer adopts the mixing method of double-sided 45-degree oblique blowing fuel. The diameter of the fuel port is (natural gas) 3mm, the diameter of the compressed air inlet is 2×6mm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com