Machine for pelletizing Chinese gerbal medicine

A technology of pill making machine and traditional Chinese medicine, which is used in the direction of making medicines into special physical or taking form devices, etc., to achieve the effect of uniform color, no cracks on the surface, and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

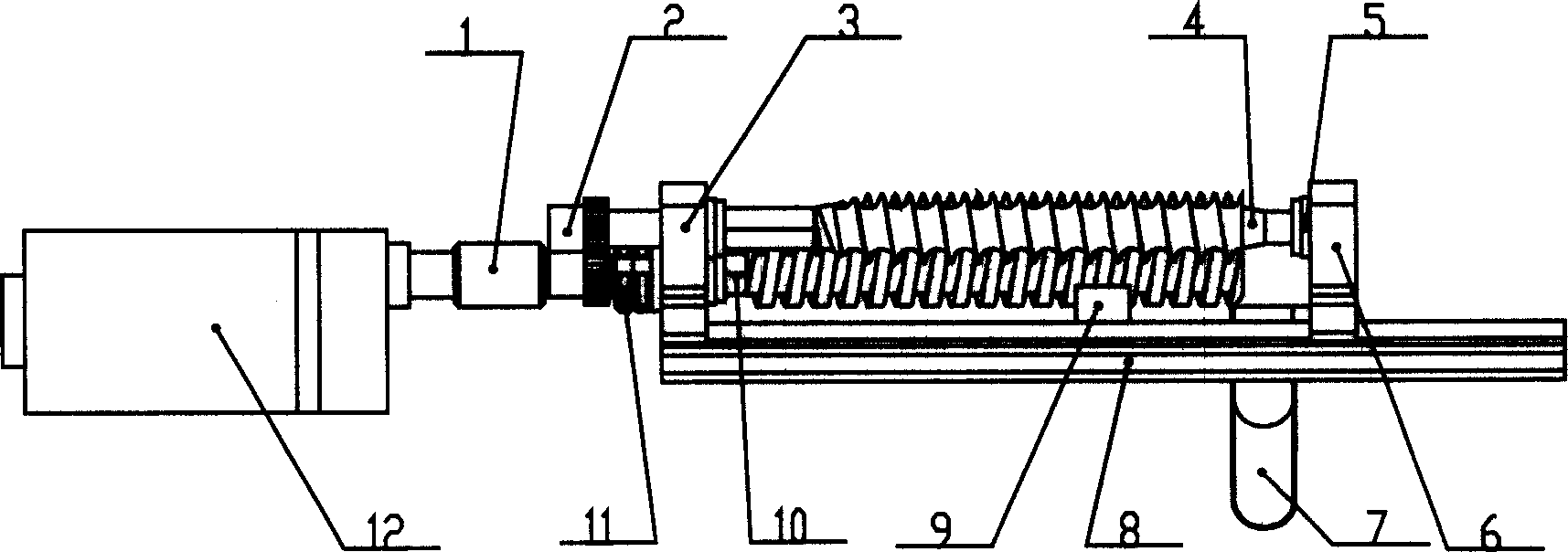

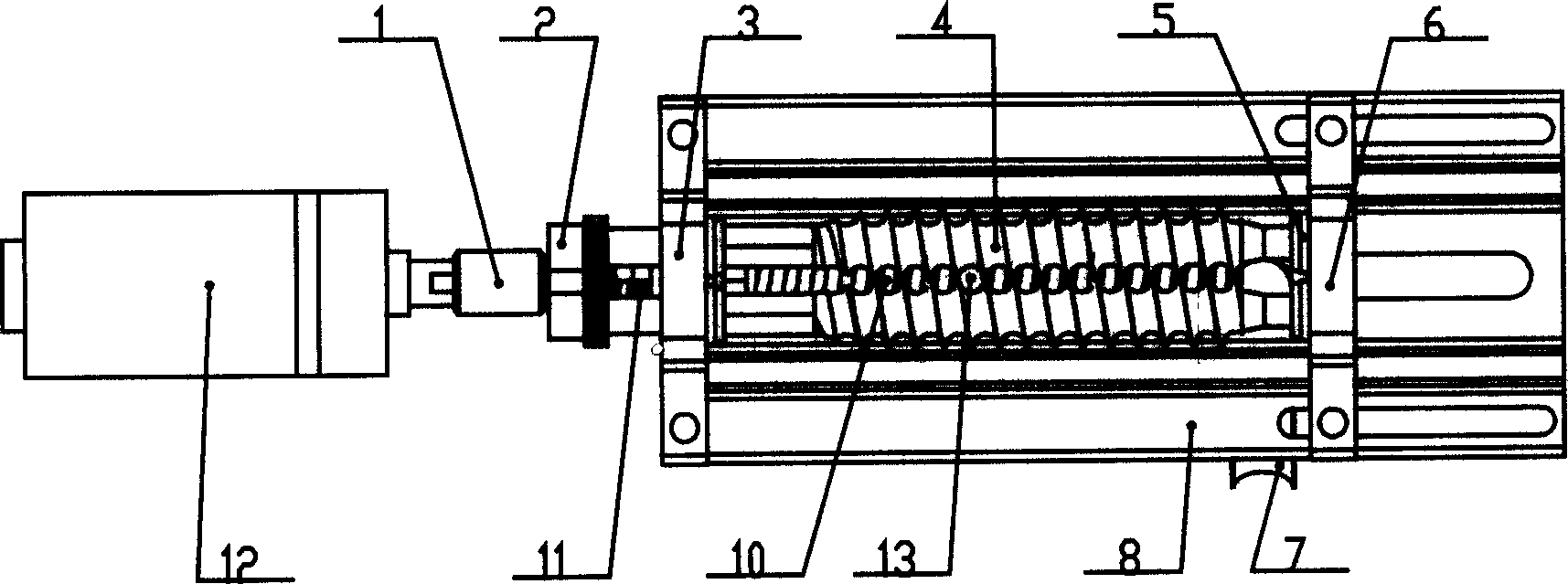

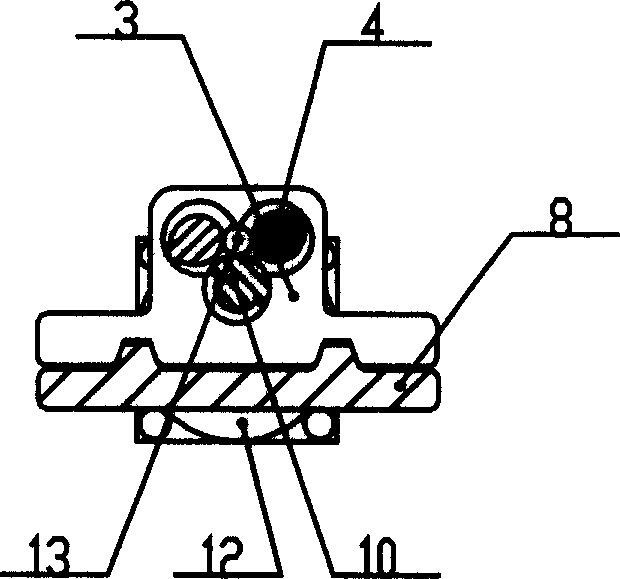

[0027] The structure of the traditional Chinese medicine pill making machine for preparing pills with a diameter of 6 mm is as follows: the AC variable frequency speed regulation motor 12 is connected to the idler roller 10 with a spiral groove on it through the coupling 1, the outer diameter of the idler roller 10 is 14 mm, and the inner diameter is 9mm. The idler 10 is fixed in the vertical direction through the fixed support 3 and the idler support 9. The axial direction of the idler 10 is fixed on the fixed support 3 by two lock nuts 11 and bearings 5, two with semicircular The rubbing roller 4 of the spiral groove is fixed in the vertical direction by the sliding support 6 and the fixed support 3, and is fixed on the sliding support 6 and the fixed support 3 by two bearings 5 horizontally. The outer diameter of the rubbing roller 4 is 15mm, and the inner diameter is 9mm. The three gears 2 are respectively fixed on the two rubbing rollers 4 and the supporting roller 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com