Battery replenishment device

A battery and extreme position technology, applied in the direction of transportation and packaging, slideways, etc., can solve the problems of production line shutdown, manual addition, and lower production efficiency of battery production lines, and achieve the effects of reducing waste, saving costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

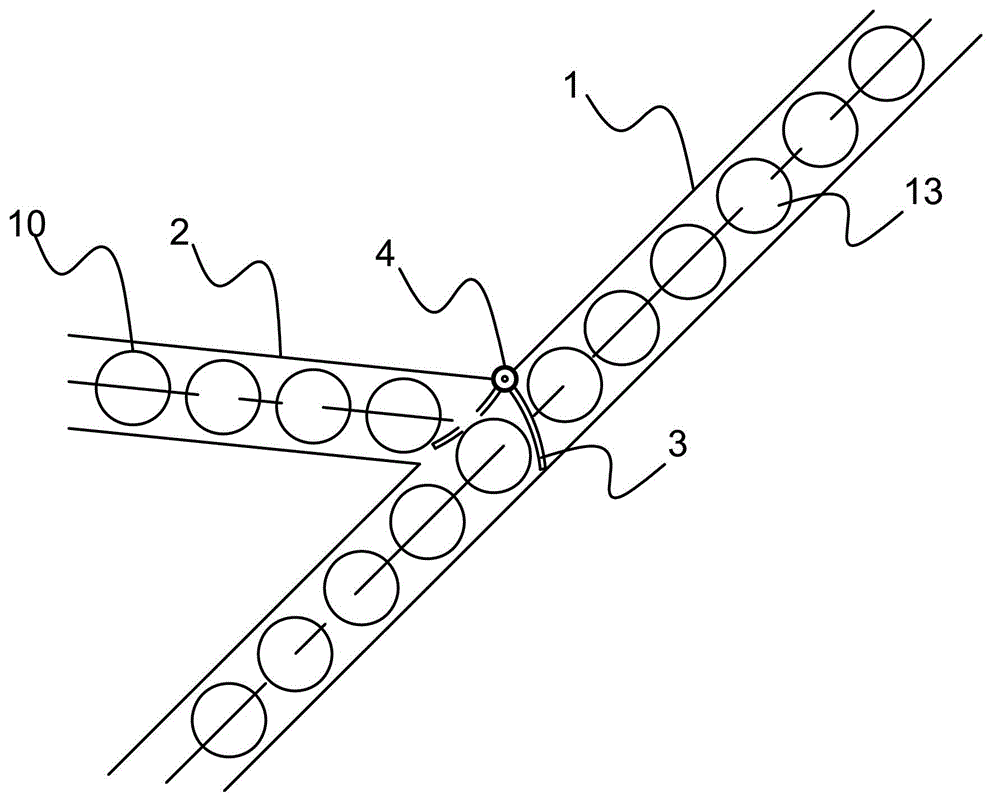

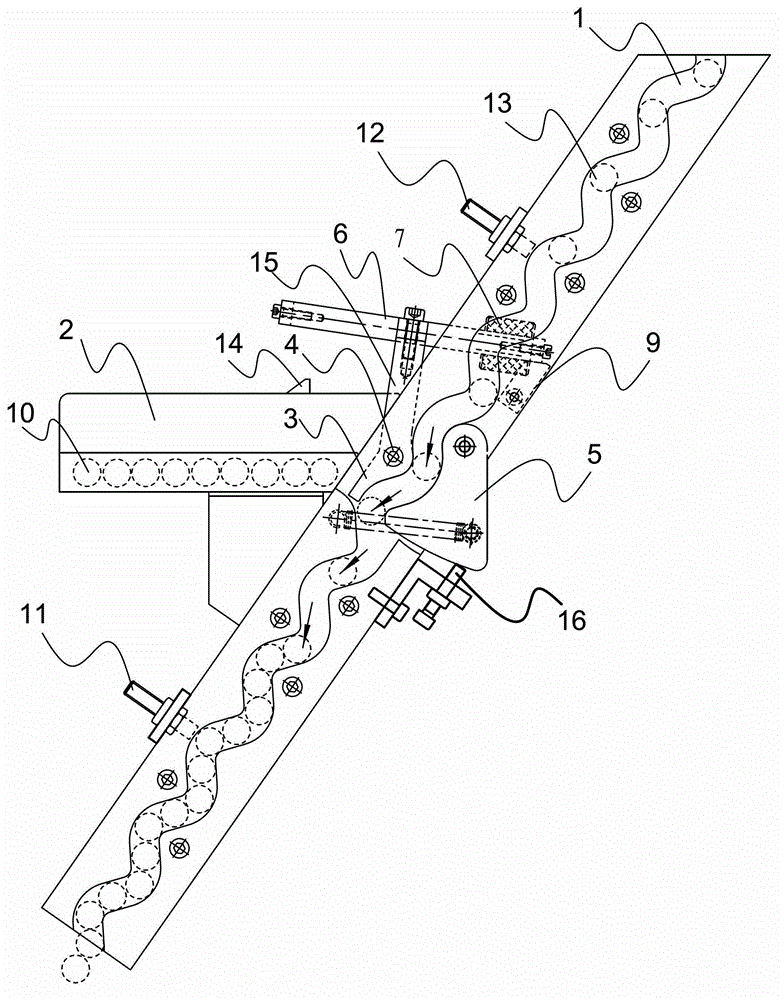

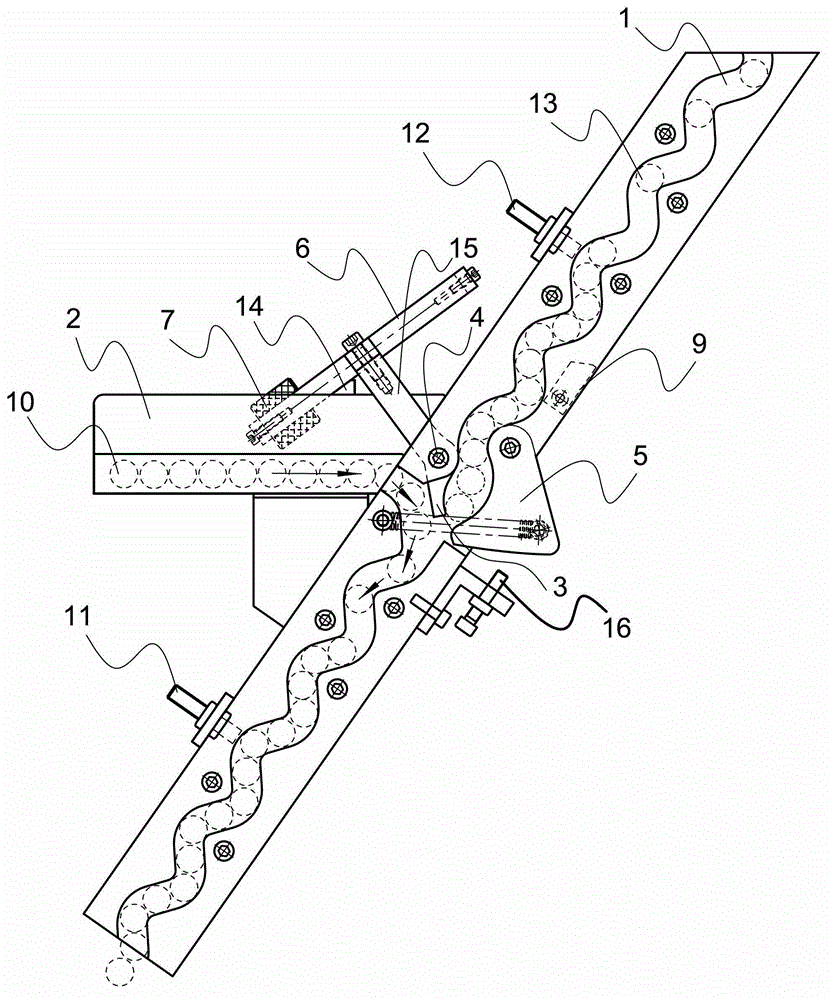

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] The invention protects a battery replenishment device, which is used to improve the existing battery conveyor belt mechanism or transmission slot mechanism, so that it can transfer the battery or battery semi-finished product from the previous process to the next process in the normal transmission state, and replenish it when necessary. When the qualified batteries or battery semi-finished products are repaired outside the assembly line, they can be replenished online without shutting down the entire battery production line equipment to avoid reducing the efficiency of the production line. At the same time, it can avoid batteries or battery semi-finished products. The hassle of manual cleaning.

[0024] Overall, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com