Method for producing yellow phosphorus from phosphate rock powder and carbon powder

A technology of phosphate rock powder and carbon powder, which is applied in the field of yellow phosphorus production, can solve the problems of high processing cost, high cost, and difficulty in briquetting, and achieve low cost, reduce production cost, and solve the effects of arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

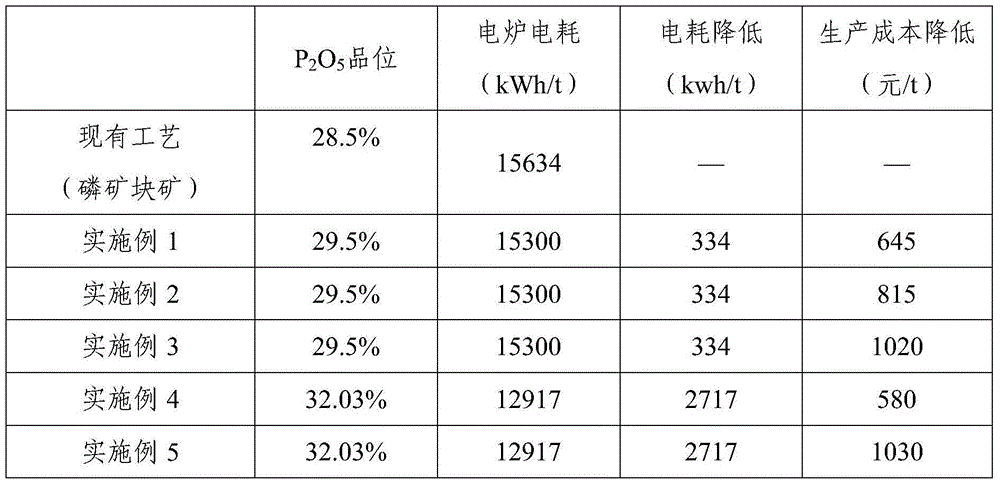

Examples

Embodiment 1

[0022] Embodiment 1 utilizes phosphate rock powder and coke powder to produce the method for yellow phosphorus

[0023] with P 2 o 5 8.48 tons of phosphate rock powder with a content of 28.5%, and 1.84 tons of coke powder with a fixed carbon content of 80%. Use a briquette machine with a pressure of 19MPa to press into pellets, sieve to obtain phosphorus coal pellets with a diameter of 5mm-30mm, dry the phosphorus coal pellets through a dryer at 350°C, and consolidate them with a consolidation machine at 650°C, and then mix them into 2.16 tons of silica, and finally sent to the yellow phosphorus electric furnace to react to produce yellow phosphorus.

[0024] Phosphate rock powder P 2 o 5 The content of coke powder is 28.5%, the moisture content is 6%, and the particle size is ≤3mm; the fixed carbon content of coke powder is 80%, the ash content is 15.5%, the volatile matter is 2%, and the moisture content is 11%.

[0025] The compressive strength of finished phosphorus c...

Embodiment 2

[0026] Embodiment 2 utilizes phosphate rock powder and blue charcoal powder to produce the method for yellow phosphorus

[0027] with P 2 o 5 Content is 8.77 tons of phosphate rock powder of 28.5%, 1.96 tons of semi-coke powder with fixed carbon content of 80%, add phosphate rock powder and semi-coke powder gross weight 4% modified crude phosphoric acid and 3% bentonite powder, mix the The material is pressed into balls by a briquetting machine with a pressure of 4MPa, and sieved to obtain phosphorus coal pellets with a diameter of 5mm-30mm. The phosphorus coal pellets are dried by a dryer at 180°C and consolidated by a consolidation machine at 640°C. Put in 2.46 tons of silica, and finally send it into the yellow phosphorus electric furnace to react to make yellow phosphorus.

[0028] Phosphate rock powder P 2 o 5 The content of carbon dioxide is 28.5%, the moisture content is 6%, and the particle size is ≤3mm; the fixed carbon content of blue charcoal powder is 80%, the ...

Embodiment 3

[0030] Embodiment 3 utilizes phosphate rock powder and white coal powder to produce the method for yellow phosphorus

[0031] with P 2 o 5 8.77 tons of phosphate rock powder with a content of 28.5%, and 2.00 tons of white coal powder with a fixed carbon content of 80%. Use a briquetting machine with a pressure of 10MPa to press into pellets, sieve to obtain phosphorus coal pellets with a diameter of 5mm-30mm, dry the phosphorus coal pellets through a dryer at 400°C, and consolidate them with a consolidation machine at 620°C, and then mix them into 2.54 tons of silica, and finally sent to the yellow phosphorus electric furnace to react to produce yellow phosphorus.

[0032] Phosphate rock powder P 2 o 5 The content of coke powder is 28.5%, the moisture content is 6%, and the particle size is ≤3mm; the fixed carbon content of coke powder is 80%, the ash content is 15.5%, the volatile matter is 2%, and the moisture content is 11%.

[0033] The compressive strength of finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com