RH refining device and method for promoting deep decarburization of molten steel

A refining device and deep decarburization technology, applied in the field of refining outside the molten steel furnace, can solve the problems of low efficiency, high oxygen content in molten steel, difficult realization and maintenance, etc., to reduce production costs, improve carbon-oxygen reaction efficiency, and be practical effect of meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

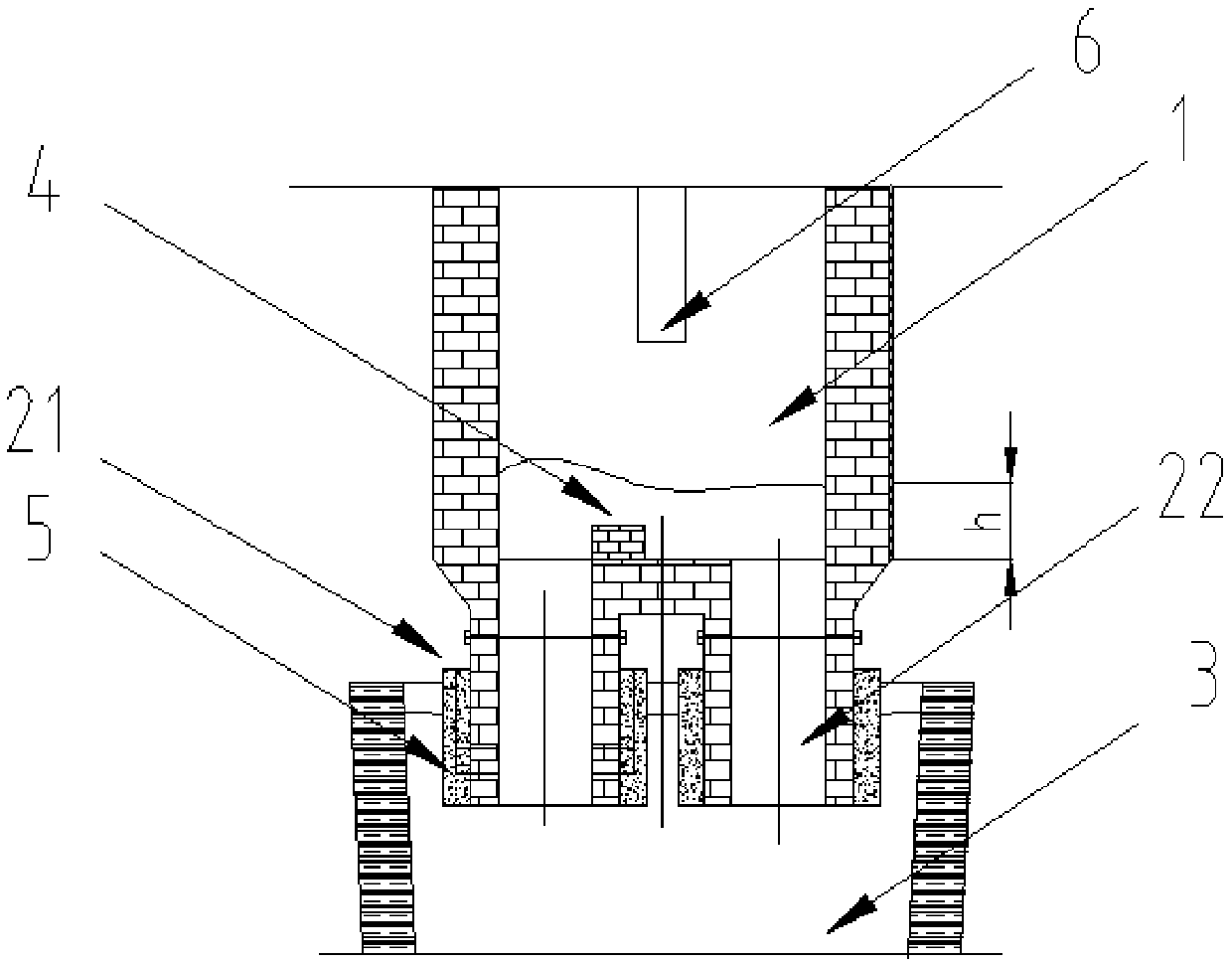

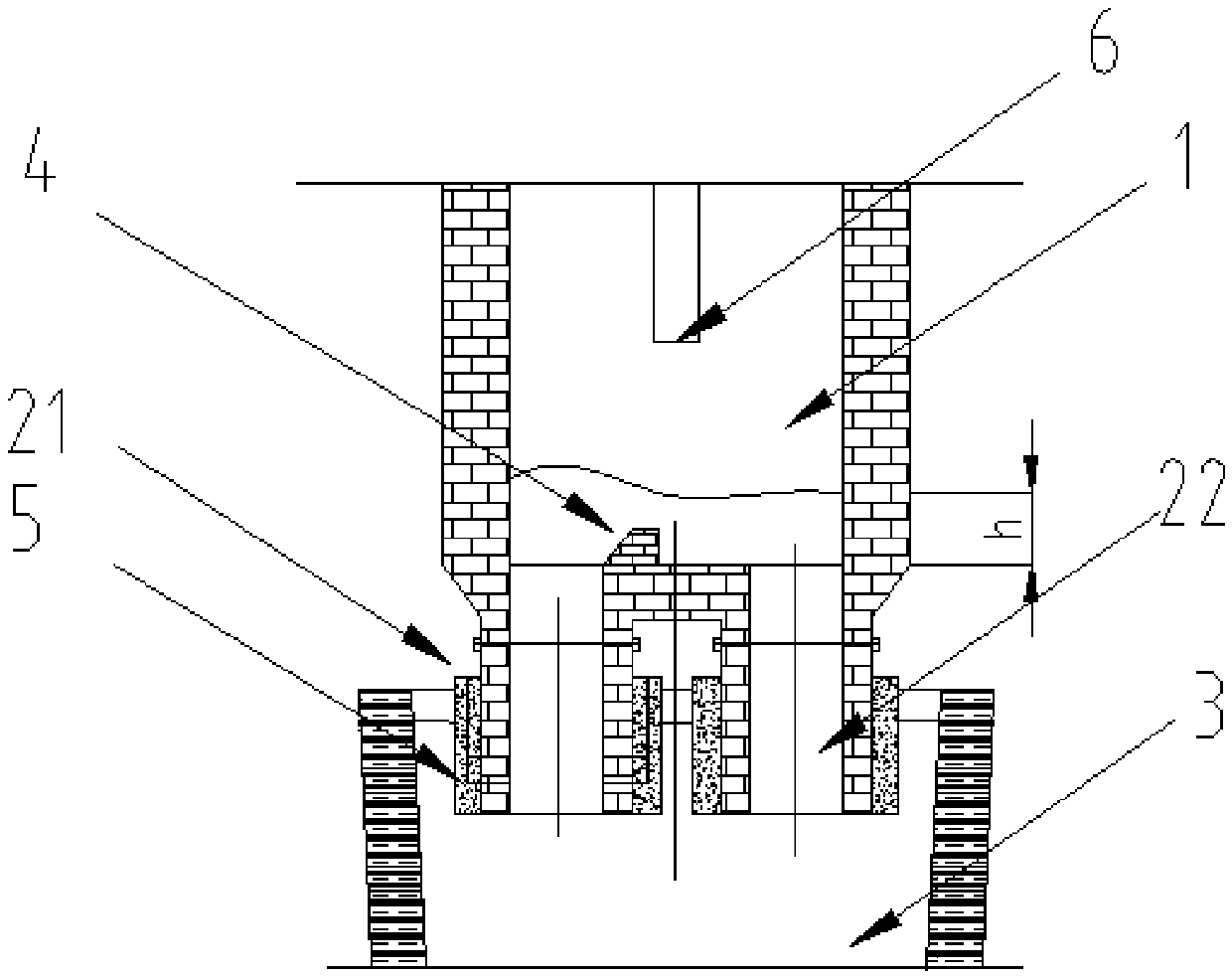

[0027] The device of the present invention will be further described with reference to the accompanying drawings.

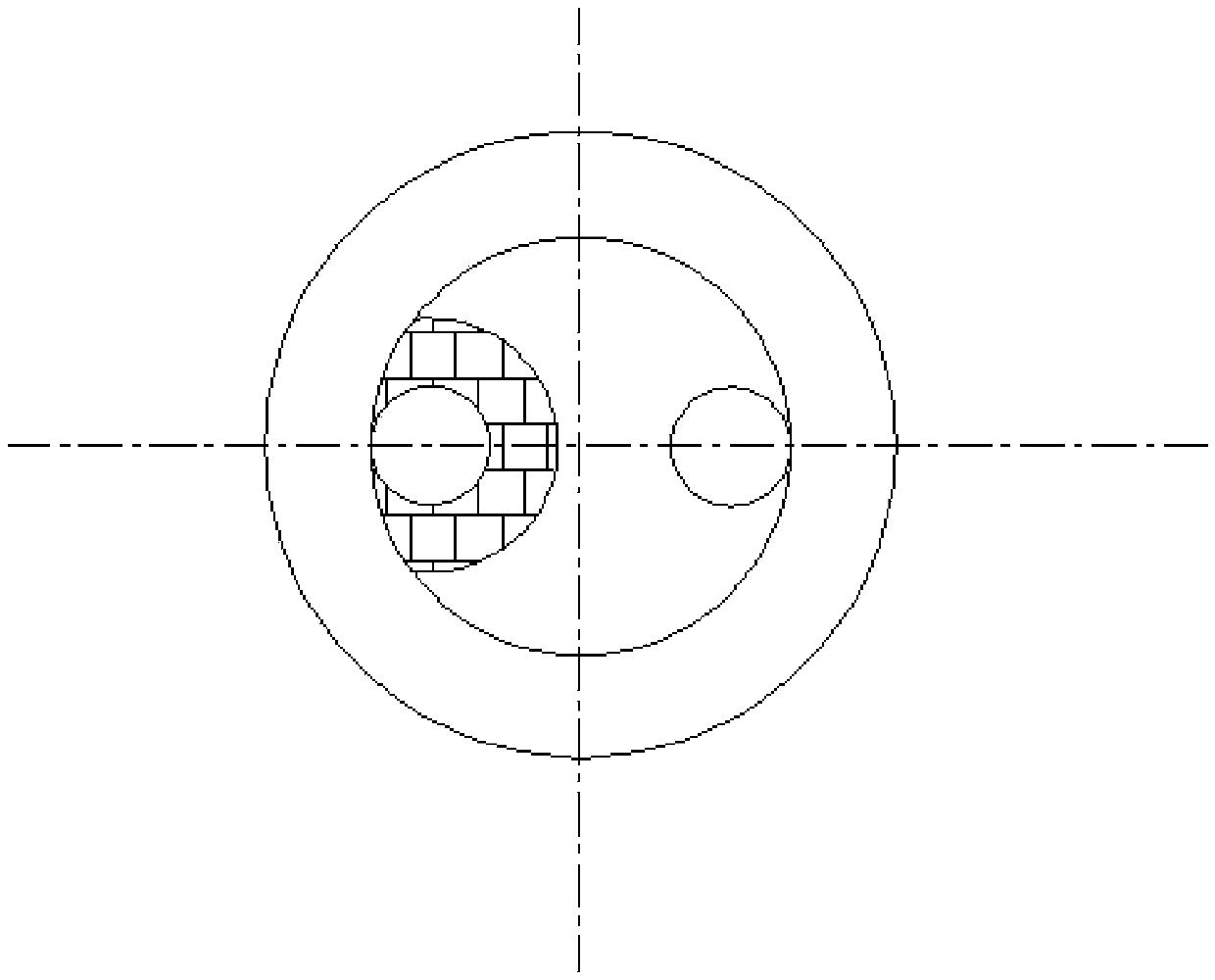

[0028] Such as figure 1 and figure 2 As shown, the deep decarburization device for vacuum refining of molten steel of the present invention includes: a vacuum chamber 1 , an ascending dipping pipe 21 , a descending dipping pipe 22 , a ladle 3 , a weir wall 4 , an argon blowing pipe 5 , and a top blowing oxygen lance 6 .

[0029] The inner diameter of the original ordinary RH dipping tube is 550m, and the inner diameter of the vacuum chamber is 1860mm. A circular weir wall is added directly above the rising dip tube at the bottom of the vacuum chamber, and the inner wall of the weir wall is flush with the inner wall of the rising dip tube, so that the molten steel flows directly into the upper part of the vacuum chamber during the rising process. The weir wall is built with fused magnesia-chrome bricks, the thickness of the weir wall is 300mm, and the height i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com