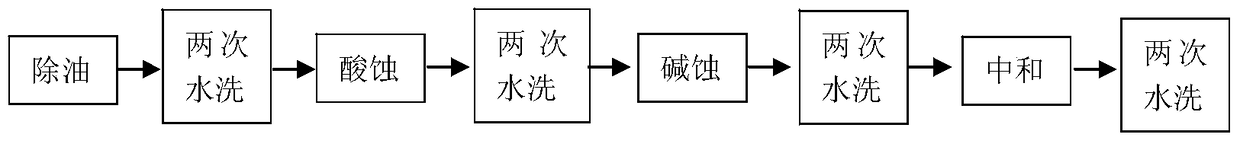

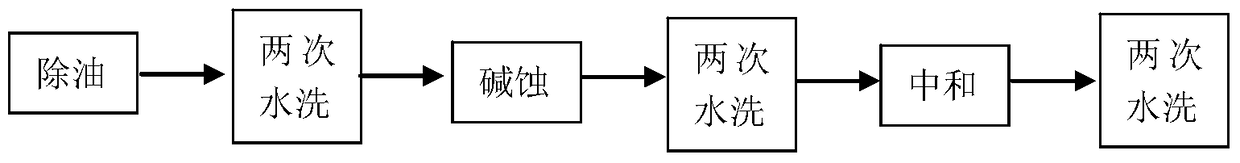

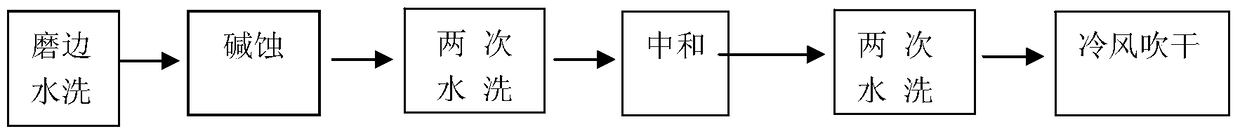

Aluminum alloy surface pretreatment method

An aluminum alloy surface and pretreatment technology, which is applied in the field of aluminum alloy surface treatment, can solve problems such as high water consumption and pollutant discharge, and achieve the effects of low water consumption, environmental friendliness, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Take the 6063 aluminum alloy and wash it with clean water;

[0037] 2) Put it into the alkali etching solution for integrated treatment of alkali etching and degreasing, and the composition of the alkali etching agent is Na 2 CO 3 , NaOH, Na 3 PO 4 , Na 2 SO 4 , sodium dodecylsulfonate, glycerin and sodium citrate, the concentration of each component is 10g / L, the temperature of the alkali etching solution is 40°C, and the integrated treatment time of alkali etching and degreasing is 10min;

[0038] 3) After the integrated treatment of alkali etching and degreasing is completed, wash with deionized water twice, each time is 1min;

[0039] 4) The aluminum profile after washing is neutralized. The main components and concentrations of the neutralizing solution are: sulfuric acid 100g / L, nitric acid 100g / L, the neutralization temperature is 25°C, and the neutralization time is 2min;

[0040] 5) After the neutralization treatment, the aluminum alloy was washed twic...

Embodiment 2

[0044]1) Take the 6063 aluminum alloy and wash it with clean water;

[0045] 2) Put it into the alkali etching solution for integrated treatment of alkali etching and degreasing. The main component of the alkali etching agent is Na 2 CO 3 , NaOH, Na 3 PO 4 , Na 2 SO 4 , sodium dodecylsulfonate, glycerin and sodium citrate, the concentration of each component is 15g / L, the temperature of the alkali etching solution is 55°C, and the integrated treatment time of alkali etching and degreasing is 8 minutes;

[0046] 3) After the integrated treatment of alkali etching and degreasing is completed, wash with deionized water twice, each time is 2 minutes;

[0047] 4) The aluminum profile after washing is neutralized. The main components and concentrations of the neutralizing solution are: sulfuric acid 120g / L, nitric acid 120g / L, neutralization temperature is 25°C, and neutralization time is 1min;

[0048] 5) After the neutralization treatment, wash the aluminum alloy twice with ...

Embodiment 3

[0052] 1) Take the 3003 aluminum alloy and wash it with clean water;

[0053] 2) Put it into the alkali etching solution for integrated treatment of alkali etching and degreasing. The main component of the alkali etching agent is Na 2 CO 3 , NaOH, Na 3 PO 4 , Na 2 SO 4 , the concentration of each component is 20g / L, the temperature of the alkali etching agent solution is 50°C, and the integrated treatment time of alkali etching and degreasing is 15min;

[0054] 3) After the integrated treatment of alkali etching and degreasing is completed, wash with deionized water twice, each time is 2 minutes;

[0055] 4) The aluminum profile after washing is neutralized. The main components and concentrations of the neutralizing solution are: 100g / L sulfuric acid, 100g / L nitric acid, the neutralization temperature is 25°C, and the neutralization time is 1min;

[0056] 5) After the neutralization treatment, wash the aluminum alloy twice with deionized water, each time being 2 minutes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com