Aluminum alloy fluorine-free and cod-free three-in-one flat-gloss pre-treatment chemical recovery system

A recovery system and a three-in-one technology, applied in the field of aluminum alloy fluorine-free and COD-free three-in-one flat-light pre-treatment agent recovery system, can solve the problems of worsening the difficulty of wastewater treatment, large amount of agents, and long time consumption, etc., to achieve the solution of fluorine pollution and COD exceed the standard, improve the surface quality and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Example group 1-production of three-in-one flat material

[0084] The formula and working index of each tank are:

[0085] 1# Three-in-one flat light tank: Ferric chloride, hydrogen peroxide, nitric acid, hydrochloric acid and nonylphenol polyoxyethylene ether are added as shown in Table 1, the balance is water; working temperature is normal temperature, processing time is 5 minutes, trickle 1 minute;

[0086] category

Example 1-1

Example 1-2

Example 1-3

2g / L

3g / L

4g / L

10g / L

10g / L

10g / L

80g / L

80g / L

80g / L

65g / L

65g / L

65g / L

Polyoxyethylene nonylphenol ether

0.001g / L

0.001g / L

0.001g / L

[0087] Table 1

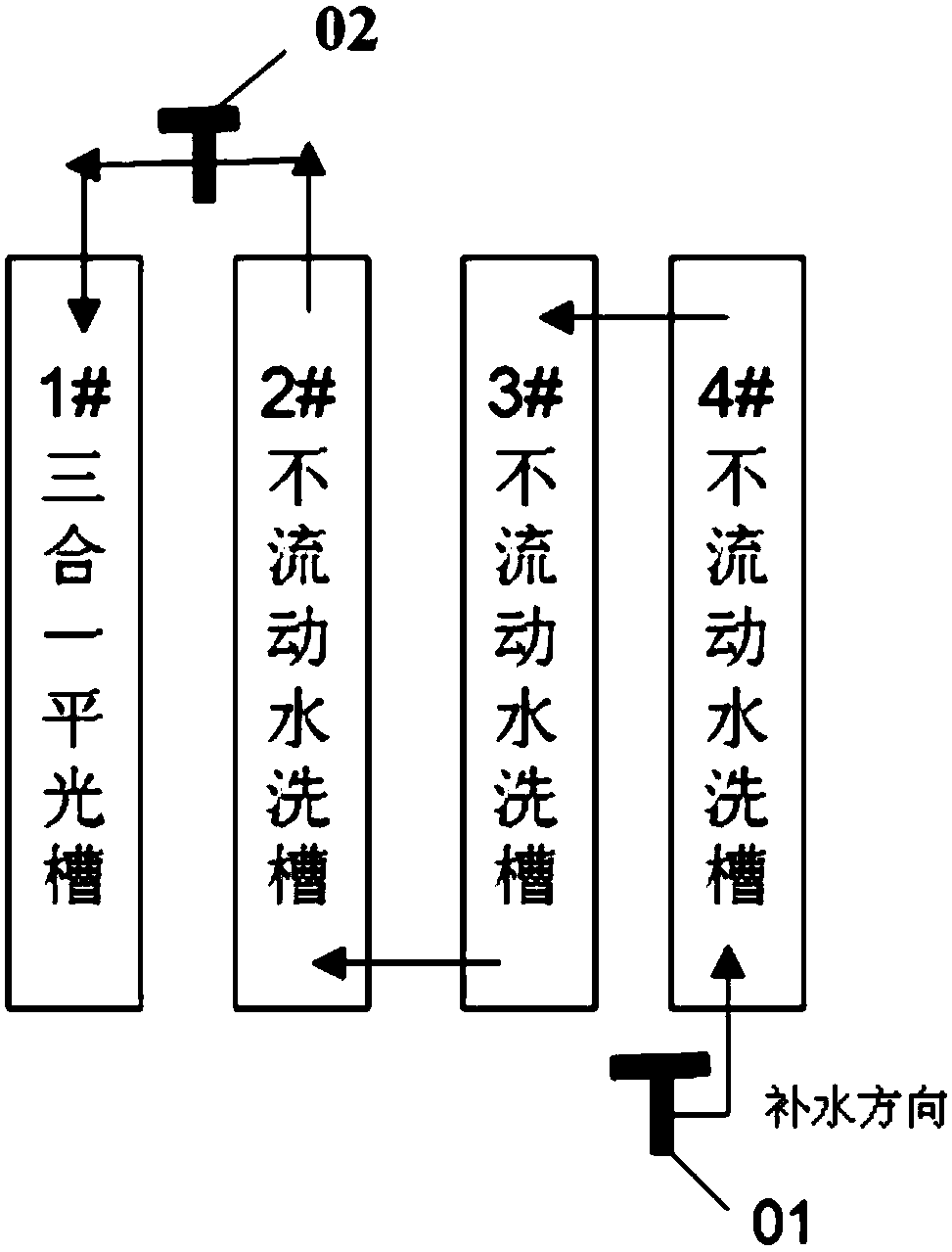

[0088] 2# No-flow washing tank: 1 minute of water washing, 30 seconds of dripping;

[0089] 3# Non-flowing washing tank: 1 minute of water washing, 30 seconds of dripping;

[0090] 4# No-flow washing tank: 1 minute of water washing, dripping for 30 seconds;

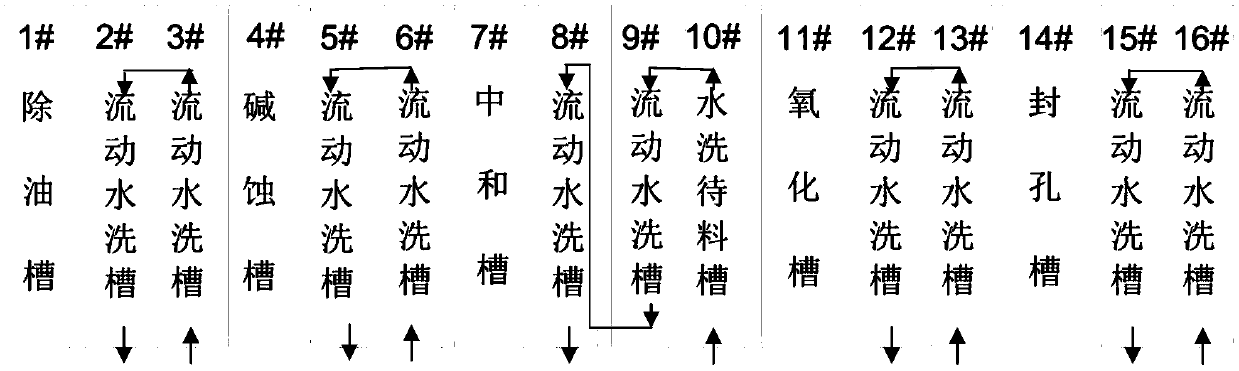

[0091] The follow-up pro...

Embodiment 2

[0093] Example 2 group-production of three-in-one flat material

[0094] The formula and working index of each tank are:

[0095] 1# Three-in-one flat tank: iron bromide, hydrogen peroxide, nitric acid, hydrochloric acid and nonylphenol polyoxyethylene ether are added as shown in Table 2, the balance is water; working temperature is normal temperature, treatment time is 5 minutes, trickle 1 minute;

[0096] category

Example 2-1

Example 2-2

Iron bromide

3g / L

3g / L

Hydrogen peroxide (50%)

8g / L

12g / L

80g / L

80g / L

hydrochloric acid

65g / L

65g / L

Polyoxyethylene nonylphenol ether

0.001g / L

0.001g / L

[0097] Table 2

[0098] 2# No-flow washing tank: 1 minute of water washing, 30 seconds of dripping;

[0099] 3# Non-flowing washing tank: 1 minute of water washing, 30 seconds of dripping;

[0100] 4# No-flow washing tank: 1 minute of water washing, dripping for 30 seconds;

[0101] The follow-up process is carried out according to the existing standard alkaline ...

Embodiment 3

[0103] Example 3 Group-Three-in-one flat material production

[0104] The formula and working index of each tank are:

[0105] 1# Three-in-one flat light tank: Ferric chloride, hydrogen peroxide, nitric acid, hydrochloric acid and nonylphenol polyoxyethylene ether are added as shown in Table 3, the balance is water; the working temperature is normal temperature, the processing time is 5 minutes, trickle 1 minute;

[0106] category

Example 3-1

Example 3-2

Example 3-3

Example 3-4

Ferric chloride

3g / L

3g / L

3g / L

3g / L

Hydrogen peroxide (50%)

10g / L

10g / L

10g / L

10g / L

70g / L

90g / L

80g / L

80g / L

hydrochloric acid

65g / L

65g / L

55g / L

75g / L

Polyoxyethylene nonylphenol ether

0.001g / L

0.001g / L

0.001g / L

0.001g / L

[0107] table 3

[0108] 2# No-flow washing tank: 1 minute of water washing, 30 seconds of dripping;

[0109] 3# Non-flowing washing tank: 1 minute of water washing, 30 seconds of dripping;

[0110] 4# No-flow washing tank: 1 minute of water wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com