Method for producing sodium chromate by roasting chromium ore and small amount of soda

A sodium chromate and roasting technology, applied in chromate/dichromate and other directions, can solve the problems of reduced chromite oxidation rate, reduced chromite utilization rate, and high treatment cost, and achieves lower reaction temperature and reduced Chromium loss and aluminum consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for producing sodium chromate by roasting chrome ore with less alkali, the weight content of each main component in the chrome ore is:

[0046] Chromium ore composition: %

Cr 2 o 3

al 2 o 3

FeO

SiO 2

CaO

MgO

50.71%

6.62%

11.86%

6.76%

0.24%

18.74%

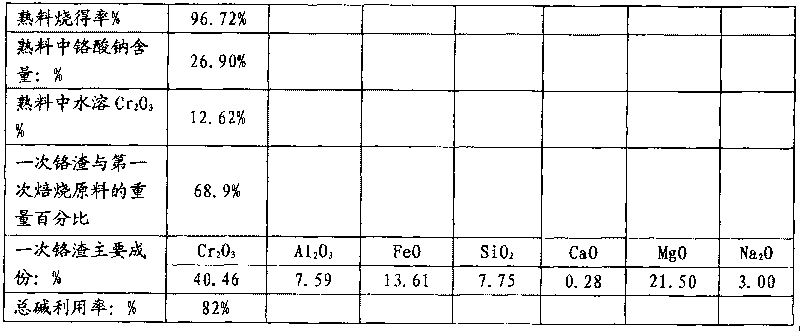

[0047] The chromium ore and soda ash are mixed in a hollow screw mixer in a ratio of 100:26.51 by weight, and the mixing uniformity is 95%. Then put into the rotary kiln for the first roasting, the material temperature in the high temperature zone in the kiln is 1000℃~1050℃, and roast in the high temperature zone 1000℃~1050℃ for 50 minutes, after the clinker is cooled and leached, chromic acid is obtained Sodium leaching solution and primary chromium slag; the data after the first roasting are shown in the table:

[0048]

[0049] After the primary chromium slag is dried and crushed, the second roasting is carried out in the ...

Embodiment 2

[0058] The method for producing sodium chromate by roasting chrome ore with less alkali, the weight percentages of each main component in the chrome ore are:

[0059] Chromium ore composition: %

Cr 2 o 3

al 2 o 3

FeO

SiO 2

CaO

MgO

43.72%

13.81%

24.96%

3.49%

0.26%

10.91%

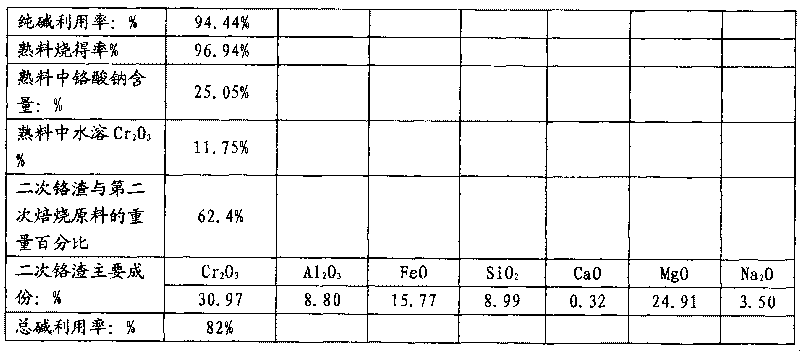

[0060] Chromium ore and soda ash are mixed in a hollow screw mixer at a ratio of 100:24.09, and the mixing uniformity is 96%. %; then put into the rotary kiln for the first roasting, the temperature of the material in the high temperature zone in the kiln is 1030 ℃ ~ 1050 ℃ and roasting for 60 minutes, after the clinker is cooled and leached, sodium chromate leaching solution and primary chromium slag are obtained; the first roasting The following data are shown in the table:

[0061]

[0062]

[0063] After the primary chromium slag is dried and crushed, the mixture is prepared according to the ratio of chromium sla...

Embodiment 3 and 4

[0073] The method for producing sodium chromate by roasting chrome ore with less alkali, the weight percentages of each main component in the chrome ore are:

[0074]

[0075] Mix chromium ore and soda ash in a hollow screw mixer with a mixing uniformity of 97%, and then put them into a rotary kiln for the first roasting. The temperature of the material in the high temperature zone in the kiln is 1000-1020 ° C for 65 minutes. After cooling and leaching, sodium chromate leaching solution and primary chromium slag are obtained;

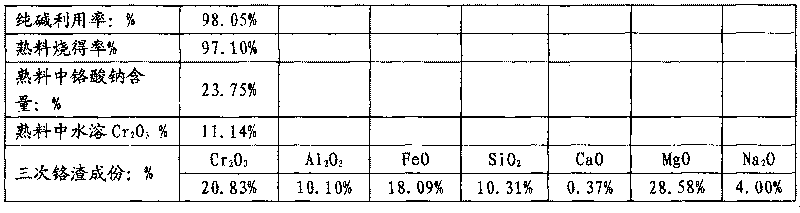

[0076] After the primary chromium slag is dried and crushed, the primary chromium slag and the newly added soda ash are roasted for the second time in the rotary kiln. Sodium chromate leaching solution and secondary chromium slag can be obtained.

[0077] After the secondary chromium slag is dried and crushed, the secondary chromium slag is mixed with soda ash, and 5% limestone (based on the total weight of the secondary chromium slag, soda ash and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com