Fluorine-free COD-free three-in-one zero-diopter pretreatment process for aluminum alloy

An aluminum alloy, three-in-one technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of worsening the difficulty of wastewater treatment, time-consuming, and high dosage of chemicals, and solve fluorine pollution and COD exceeding the standard. , The effect of reducing production costs and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

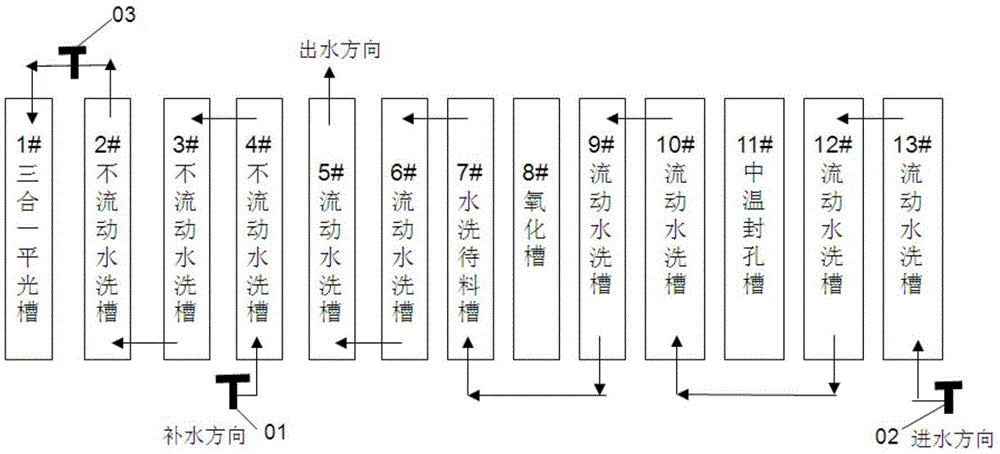

[0114] Example 1 group - production of three-in-one flat light material

[0115] The medicine formula and working index of each tank are:

[0116] 1# three-in-one flat tank: ferric chloride, hydrogen peroxide, nitric acid, hydrochloric acid and nonylphenol polyoxyethylene ether are added according to Table 1, and the balance is water; the working temperature is normal temperature, the processing time is 5 minutes, drip 1 minute;

[0117] category

Example 1-1

Example 1-2

Example 1-3

2g / L

3g / L

4g / L

10g / L

10g / L

10g / L

80g / L

80g / L

80g / L

65g / L

65g / L

65g / L

Nonylphenol polyoxyethylene ether

0.001g / L

0.001g / L

0.001g / L

[0118] Table 1

[0119] 2# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds;

[0120] 3# Non-flowing water washing tank: water washing for 1 ...

Embodiment 2

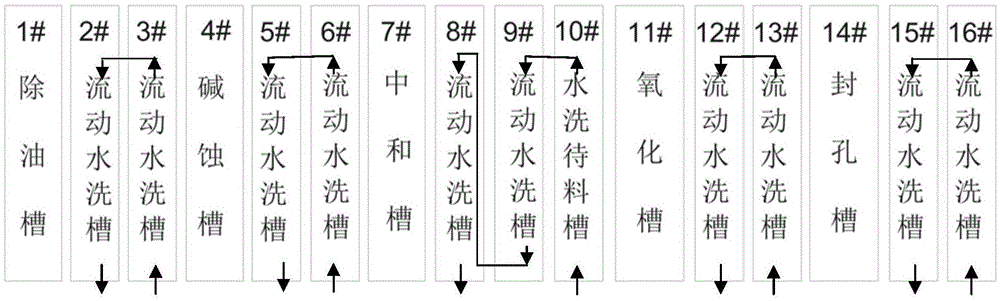

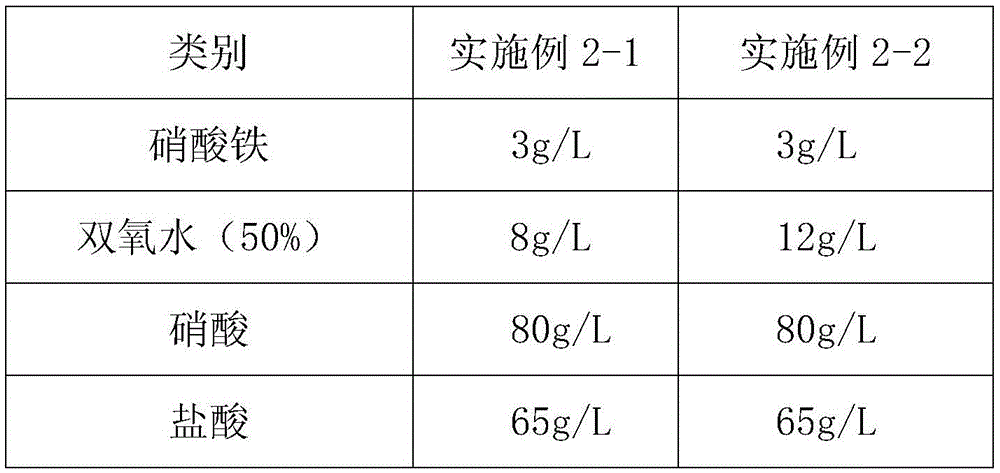

[0133] Example 2 group - production of three-in-one flat light material

[0134] The medicine formula and working index of each tank are:

[0135] 1# three-in-one flat tank: ferric nitrate, hydrogen peroxide, nitric acid, hydrochloric acid and nonylphenol polyoxyethylene ether are added according to Table 2, and the balance is water; the working temperature is normal temperature, the processing time is 5 minutes, and the trickle is 1 minute ;

[0136]

[0137]

[0138] Table 2

[0139] 2# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds;

[0140] 3# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds;

[0141]4# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds;

[0142] 5# Flowing water washing tank: washing for 1 minute, dripping for 30 seconds;

[0143] 6# Flowing washing tank: washing for 1 minute, dripping for 30 seconds;

[0144] 7# Flowing water washing waiti...

Embodiment 3

[0153] Example 3 group - three-in-one flat light material production

[0154] The medicine formula and working index of each tank are:

[0155] 1# three-in-one flat tank: ferric chloride, hydrogen peroxide, nitric acid, hydrochloric acid and nonylphenol polyoxyethylene ether are added according to Table 3, and the balance is water; the working temperature is normal temperature, the processing time is 5 minutes, drip 1 minute;

[0156] category

Example 3-1

Example 3-2

Example 3-3

Example 3-4

Ferric chloride

3g / L

3g / L

3g / L

3g / L

Hydrogen peroxide (50%)

10g / L

10g / L

10g / L

10g / L

nitric acid

70g / L

90g / L

80g / L

80g / L

hydrochloric acid

65g / L

65g / L

55g / L

75g / L

Nonylphenol polyoxyethylene ether

0.001g / L

0.001g / L

0.001g / L

0.001g / L

[0157] table 3

[0158] 2# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com