Method for regulating oxygen atmosphere in fuel oil (gas) reverberatory furnace by using recovered fume

A technology of reverberatory furnace and oxygen atmosphere, applied in the field of energy saving of fuel reverberatory furnace, can solve the problems of uncontrollable oxygen atmosphere and increased energy saving potential, and achieve the effects of reducing energy consumption, improving utilization rate and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

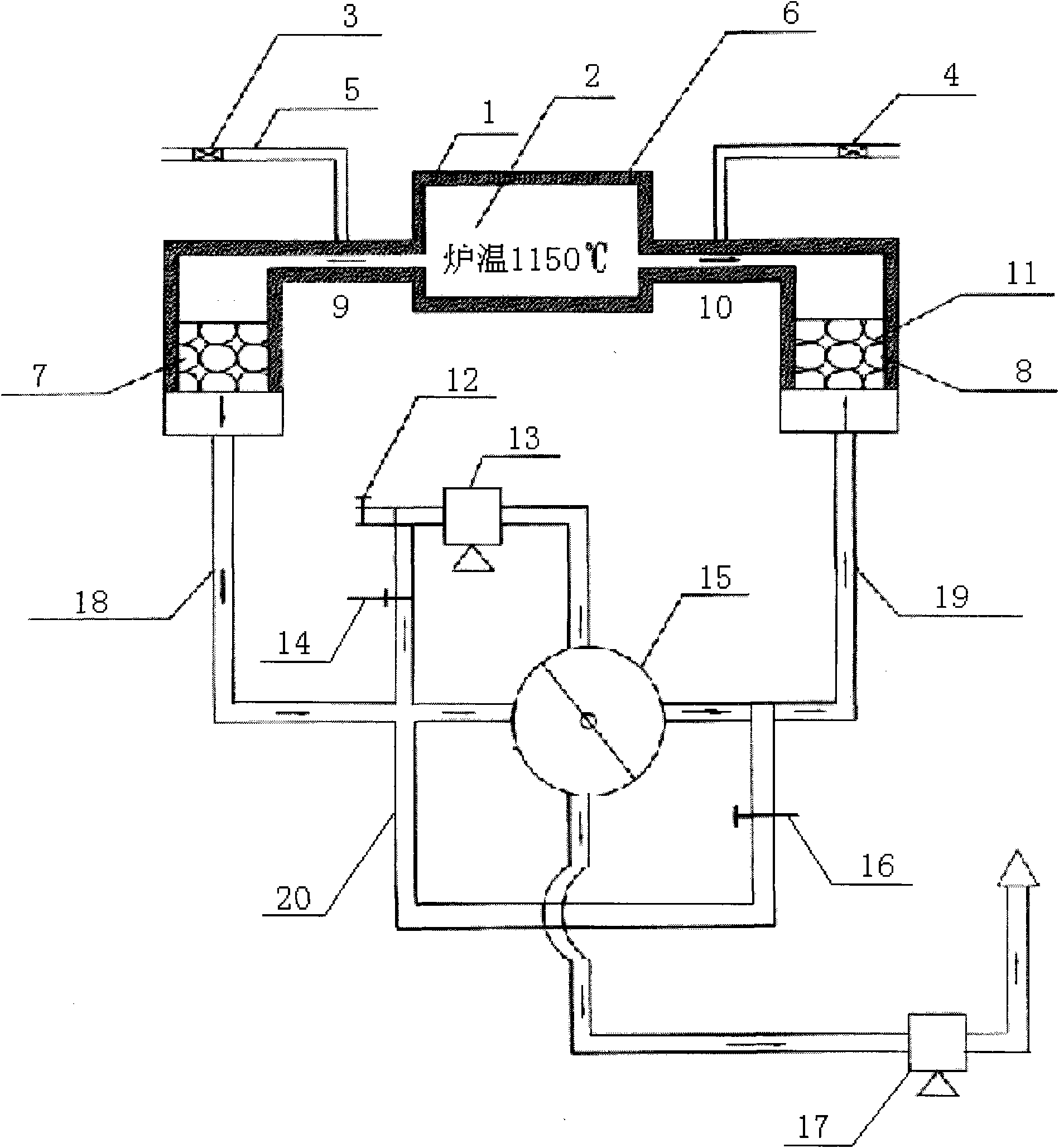

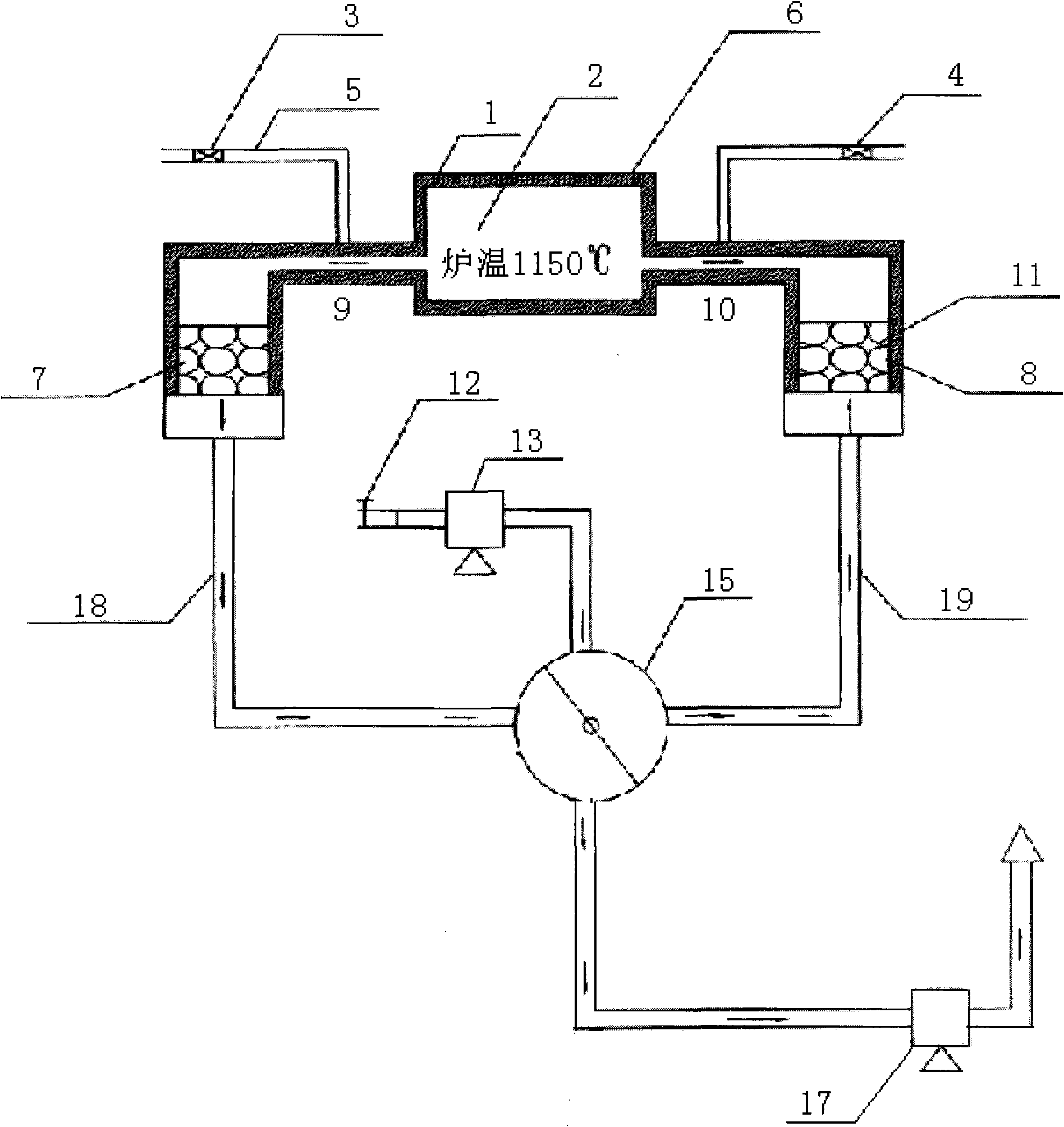

[0024] The specific embodiment of the present invention is as figure 1 As shown in the figure, it is a structural schematic diagram of a high-efficiency and energy-saving aluminum melting reverberatory furnace with low-temperature flue gas recovery and modulation atmosphere. In this embodiment, on the basis of the fuel (gas) reverberatory furnace structure of HTAC regenerative high-temperature combustion technology, a low-temperature flue gas recovery pipeline is added. A low-temperature flue gas recovery pipe 20 is added to the flue gas pipe 18 between the heat storage body A and the four-position reversing valve 15. A part of the pipe is connected to the air intake end of the blower, and a flue gas regulating valve A is installed on this part of the pipe. The other part is connected with the pipe 19 leading to the heat storage body B from the four-position reversing valve 15, and the flue gas regulating valve B is set on this part of the pipe.

[0025] When the controllabl...

Embodiment 2

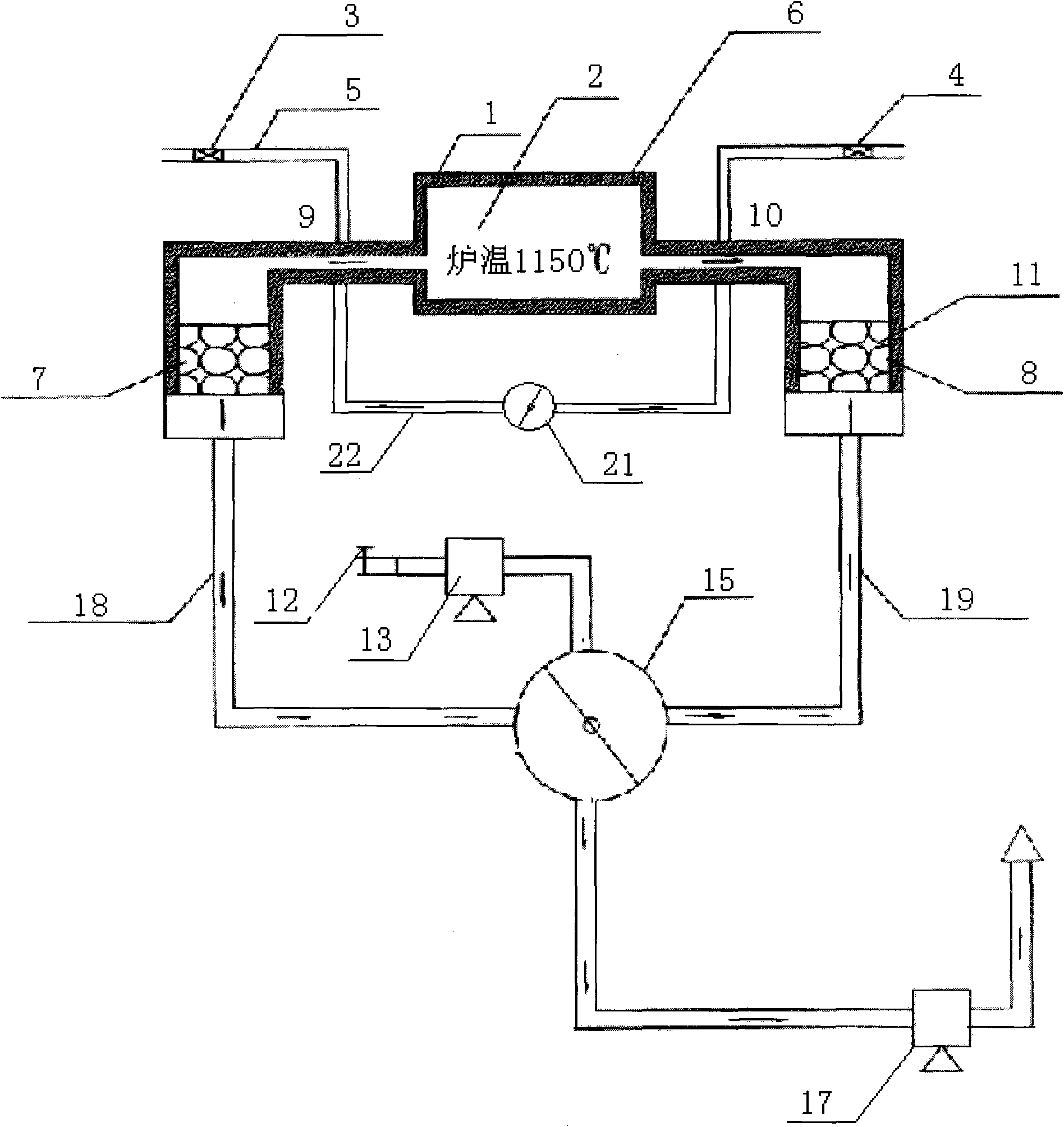

[0029] Another specific embodiment of the present invention is as image 3 Shown is a schematic diagram of the high-temperature flue gas recovery modulation atmosphere regenerative energy-saving reverberatory furnace for melting aluminum. In this embodiment, on the basis of the fuel (gas) reverberatory furnace structure of HTAC regenerative high-temperature combustion technology, a high-temperature flue gas recovery pipeline is added. A high-temperature flue gas recovery pipe 22 is added at the high-temperature flue gas outlets at both ends of the furnace body 1, and a high-temperature flue gas reversing regulating valve 21 is arranged in the middle of the high-temperature flue gas recovery pipe. According to the measured results of the oxygen content in the furnace, the intake volume of the recovered high-temperature flue gas can be controlled by adjusting the flue gas reversing regulating valve, so that the oxygen atmosphere in the furnace combustion chamber can always be ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com