Surface pre-treatment system combining four aluminum alloy working grooves into whole for full recovery of medicament and zero emission of wastewater

A technology of treatment system and recovery system, which is applied in the field of aluminum alloy surface treatment technology and environmental protection, can solve the problems of reducing the pollution control amount of enterprises, reducing production costs, high costs of fluorine and ammonia nitrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

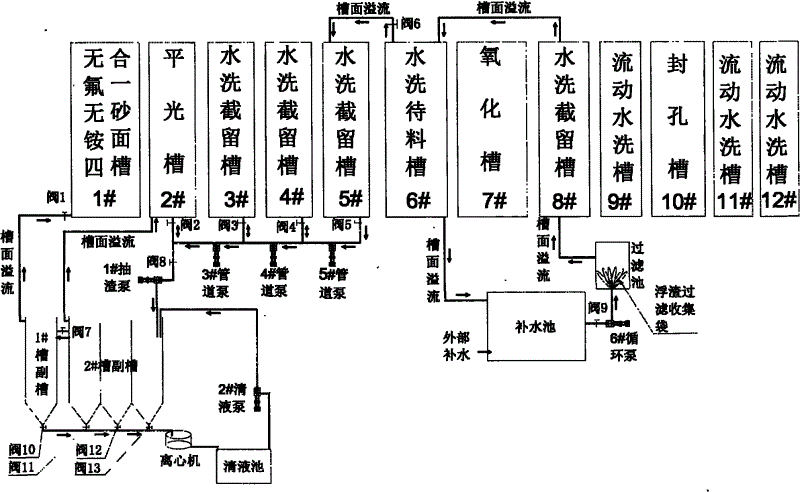

[0166] Embodiment 1 (sand surface material)

[0167] 1# Four-in-one sand tank: NaOH 60g / L, NaOH 2 SO 4 10g / L, Na 3 PO 4 10g / L, 5g / L sorbitol, 0.3g / L sodium dodecyl sulfonate, the rest of water; the working temperature is 65°C, the processing time is 8 minutes, trickle for 1 minute;

[0168] 2# flat surface tank; the concentration of the agent is 30% of the concentration of 1# four-in-one sand surface tank, the working temperature is 50°C, the treatment time is 4 minutes, and the trickle flow is 1 minute;

[0169] 3# Washing retention tank; water washing for 1 minute, dripping for 30 seconds;

[0170] 4# washing retention tank: washing for 1 minute, dripping for 30 seconds;

[0171] 5# washing retention tank: washing for 1 minute, dripping for 30 seconds;

[0172] 6#Water washing waiting tank: wash with water for 1 minute, trickle for 30 seconds.

Embodiment 2

[0173] Embodiment 2 (sand surface material)

[0174] 1# Four-in-one sand surface tank: NaOH 180g / L, NaOH 2 SO 4 30g / L, Na 3 PO 4 30g / L, 15g / L sorbitol, 0.6g / L sodium dodecyl sulfonate, the rest of water; the working temperature is 60°C, the treatment time is 6 minutes, trickling for 1 minute;

[0175] 2# flat tank; the concentration of the agent is 40% of the concentration of the 1# four-in-one sand surface, the working temperature is 45°C, the processing time is 3 minutes, and the drip flow is 1 minute;

[0176] 3# Washing retention tank; water washing for 1 minute, dripping for 30 seconds;

[0177] 4# washing retention tank: washing for 1 minute, dripping for 30 seconds;

[0178] 5# washing retention tank: washing for 1 minute, dripping for 30 seconds;

[0179] 6#Water washing waiting tank: wash for 1 minute, trickle for 30 seconds;

Embodiment 3

[0180] Embodiment 3 (sand surface material)

[0181] 1# Four-in-one sand tank: NaOH 300g / L, NaOH 2 SO 4 50g / L, Na 3 PO 4 50g / L, sorbitol 25g / L, sodium dodecylsulfonate 0.9g / L, the balance of water; the working temperature is 55°C, the processing time is 4 minutes, trickling for 1 minute;

[0182] 2# flat surface tank; the concentration of the agent is 50% of the concentration of 1# four-in-one sand surface tank, the working temperature is 40 ℃, the treatment time is 2 minutes, and the drip flow is 1 minute;

[0183] 3# Washing retention tank; water washing for 1 minute, dripping for 30 seconds;

[0184] 4# washing retention tank: washing for 1 minute, dripping for 30 seconds;

[0185] 5# washing retention tank: washing for 1 minute, dripping for 30 seconds;

[0186] 6#Water washing waiting tank: wash for 1 minute, trickle for 30 seconds;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com