Aluminum liquid backwater circulating device of smelting heat-holding furnace

A technology of a circulation device and a holding furnace, which is applied in the directions of furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of high temperature requirements of the holding room, short service life of the holding room, and large fuel waste, and achieves fuel saving and simple structure. , The effect of reducing aluminum consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

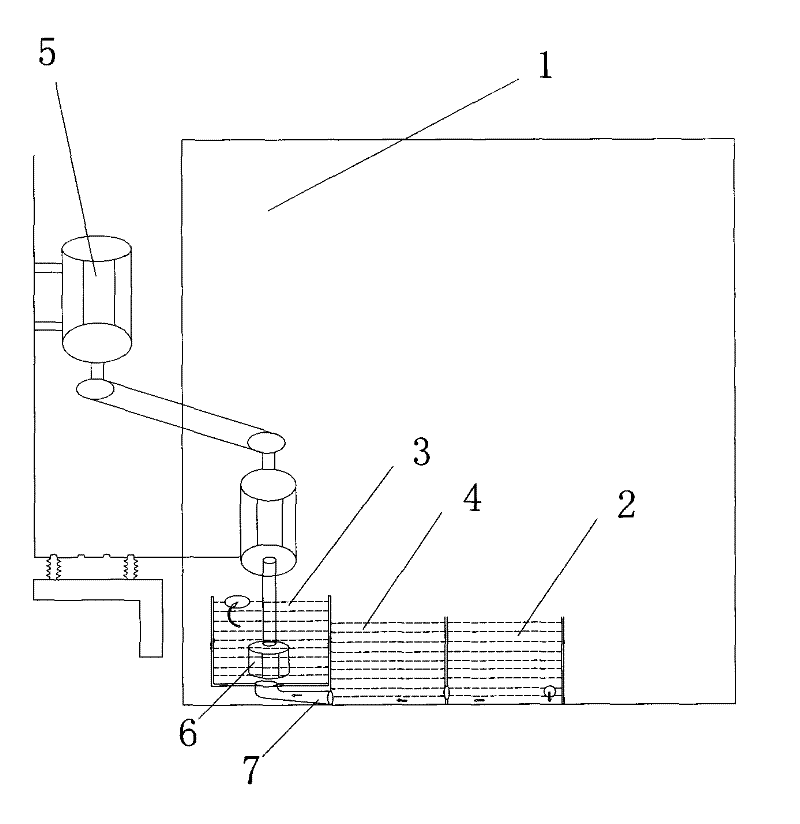

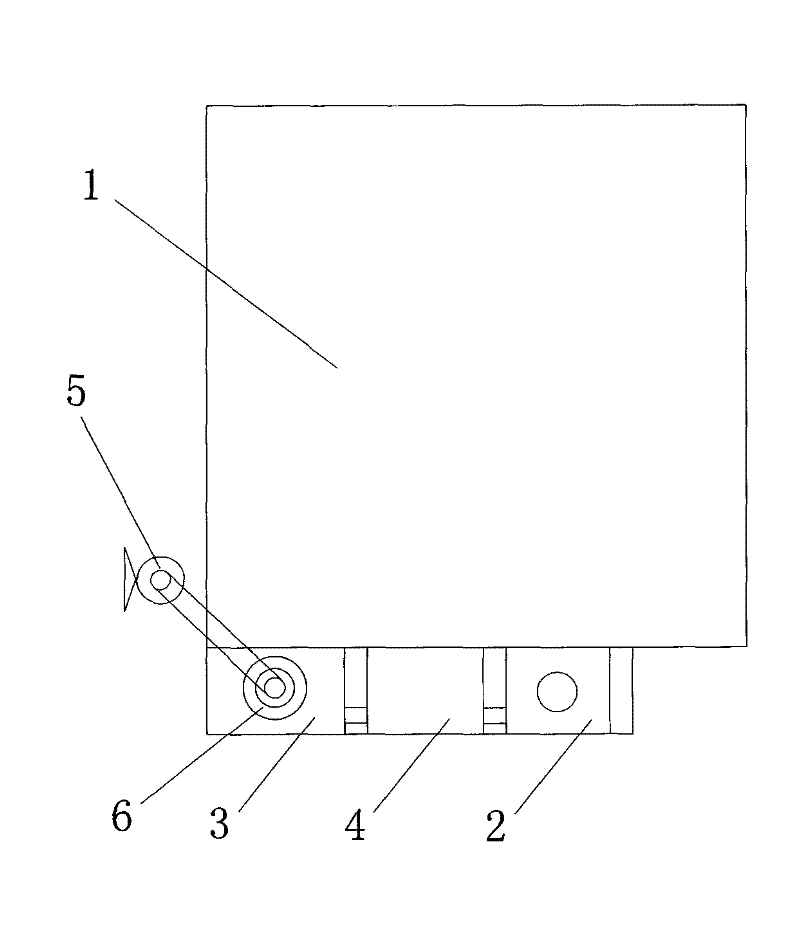

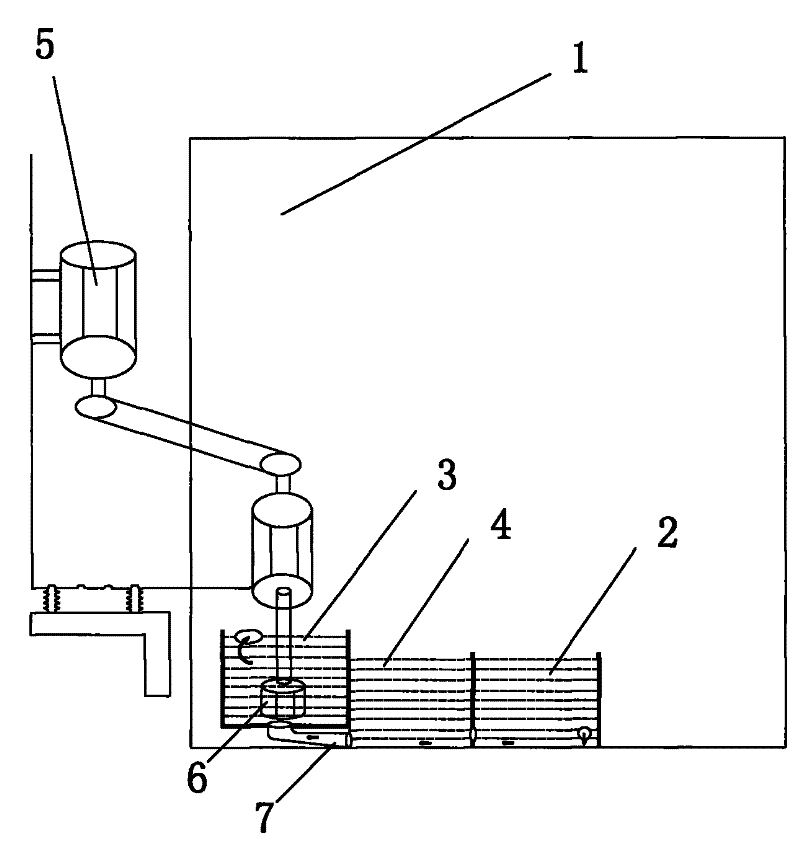

[0012] refer to Figure 1-2 , an aluminum soup backwater circulation device for a smelting and holding furnace, including a holding room 1, a degassing room 2, a static room and a use room 4 connected to each other, and also includes a lifting device, and the lifting device includes a backwater room 3 , motor 5 and graphite rod 6, described backwater chamber is provided with water inlet hole and water outlet hole, and described backwater chamber communicates 7 with first pipeline through first pipeline; Described backwater chamber and insulation chamber pass second pipeline connected, the second pipe is arranged obliquely from top to bottom, the upper end is connected with the water outlet hole of the backwater chamber, and the lower end is connected with the water inlet hole of the heat preservation chamber, and the water outlet hole of the backwater chamber and the water inlet hole of the heat preservation chamber are respectively It is located above the soup surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com