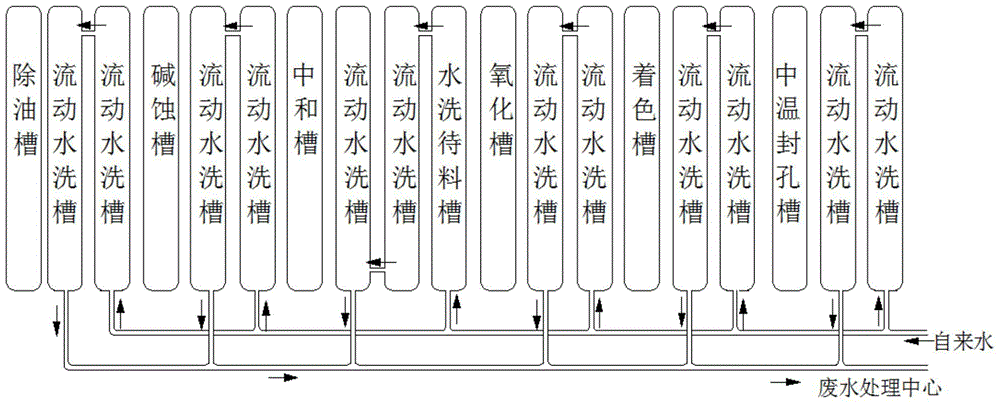

Aluminum alloy anodizing line treatment process

A treatment process and oxidation line technology, applied to the chemical industry, can solve the problems of chemical consumption, inevitable stringing, mutual consumption of pharmaceuticals, etc., and achieve the effects of improving efficiency, reducing production costs, and reducing pollution control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

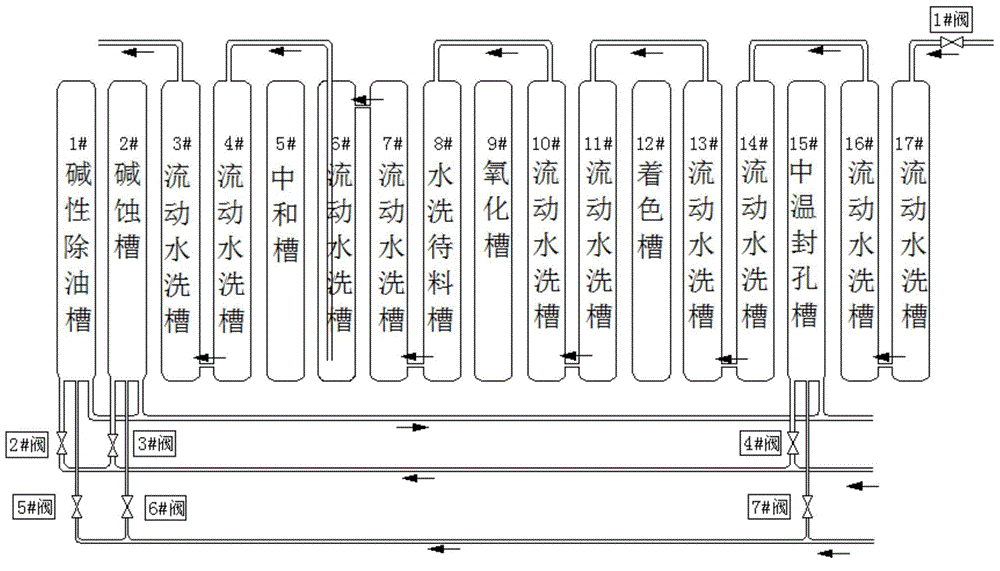

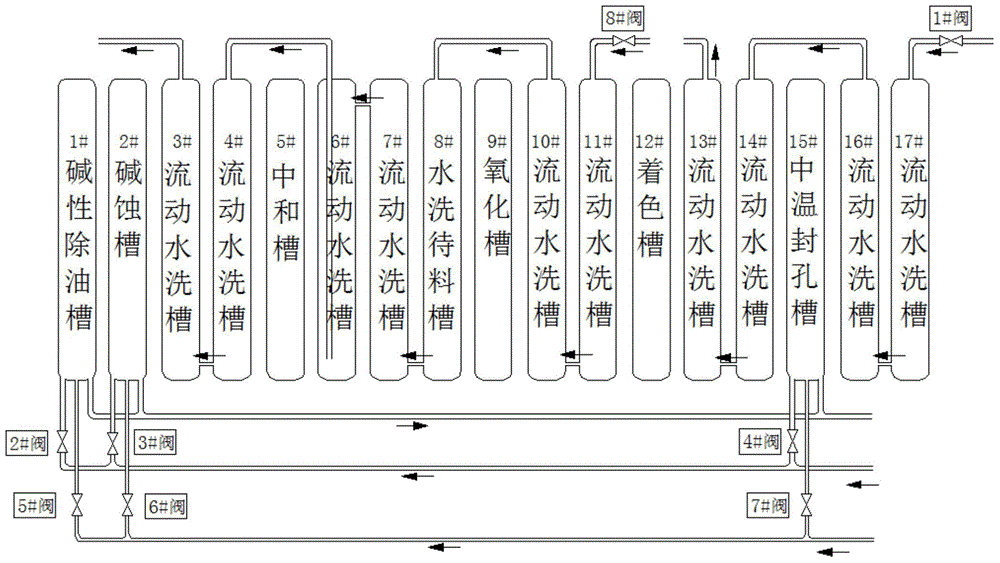

Method used

Image

Examples

Embodiment 112

[0158] Embodiment 112# coloring bath liquid stability detection

[0159] Preparation of coloring solution: phosphonobutane tricarboxylic acid 30g / L, sulfuric acid 18g / L, nickel sulfate 25g / L, pH 1.0. Prepare stannous sulfate according to different concentrations, store it sealed for half a year, observe the clarity of the bath solution, and confirm the chelating ability of phosphonobutane tricarboxylic acid to stannous sulfate and the appropriate concentration ratio. The experimental results are shown in the table below.

[0160] Table 4

[0161] Stannous sulfate (g / L)

5

10

15

20

25

30

Bath clarity

clear

clear

clear

Slightly muddy

cloudy

[0162] Table 4 shows that:

[0163] 1. Add stannous sulfate to the coloring solution, store it at room temperature for half a year, below 15g / L, the bath solution is clear, very stable, and does not decompose;

[0164] 2. As the addition of stannous sulfa...

Embodiment 2

[0166] Example 2 Compatible Detection of Functional Tank Drugs

[0167] The present invention takes 150L tank volume to design the simulated oxidation line, and each functional tank is slotted according to 100L, and the bath liquid control parameters are:

[0168] 1.1# alkaline degreasing tank

[0169] Sodium carbonate 10g / L

[0170] Sodium tripolyphosphate 10g / L

[0171] Sodium silicate 10g / L

[0172] Temperature 55°C

[0173] time 2 minutes

[0174] 2.2# alkali etching tank

[0175] Sodium hydroxide 55g / L

[0176] Sodium gluconate 15g / L

[0177] Sodium tripolyphosphate 4g / L

[0178] Sorbitol 3g / L

[0179] Sodium thiosulfate 2g / L

[0180] Temperature 55°C

[0181] time 5 minutes

[0182] 3.5# neutralization tank

[0183] Sulfuric acid 160g / L

[0184] Aluminum ion 20g / L

[0185] Normal temperature

[0186] Time 5-15 minutes

[0187] 4.9# oxidation tank

[0188] Sulfuric acid 160g / L

[0189] Aluminum ion 5g / L

[0190] Temperature 18°C

[0191] time 25 minut...

Embodiment 3

[0211] Embodiment 3 Functional tank drug compatibility detection

[0212] The present invention takes 150L tank volume to design the simulated oxidation line, and each functional tank is slotted according to 100L, and the bath liquid control parameters are:

[0213] 1.1# alkaline degreasing tank

[0214] Sodium carbonate 30g / L

[0215] Sodium tripolyphosphate 30g / L

[0216] Sodium silicate 30g / L

[0217] Temperature 65°C

[0218] time 4 minutes

[0219] 2.2# alkali etching tank

[0220] Sodium hydroxide 65g / L

[0221] Sodium gluconate 20g / L

[0222] Sodium tripolyphosphate 8g / L

[0223] Sorbitol 5g / L

[0224] Sodium thiosulfate 4g / L

[0225] Temperature 65°C

[0226] time 15 minutes

[0227] 3.5# neutralization tank

[0228] Sulfuric acid 200g / L

[0229] Aluminum ion 25g / L

[0230] Temperature Room temperature

[0231] time 15 minutes

[0232] 4.9# oxidation tank

[0233] Sulfuric acid 200g / L

[0234] Aluminum ion 20g / L

[0235] Temperature 22°C

[0236] t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com