Iron core aluminum-iron composite deoxidizing agent

A technology of composite deoxidizer and iron core aluminum, which is applied in the field of aluminum-iron composite deoxidizer, can solve the problems of poor deoxidation effect, refractory, easy oxidation and rust, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Take the following aluminum and iron raw materials: 85 kg of aluminum ingots, 15 kg of iron filings, 35 kg of iron nuggets and iron pellets;

[0025] 2. Heat 85kg aluminum ingot to 750-900℃ to melt it into molten aluminum;

[0026] 3. Add 15 kg of iron filings to the above molten aluminum, continue to heat up to 1000-1200°C, so that the iron filings are completely melted in the molten aluminum, and stir evenly to obtain an aluminum-iron alloy liquid;

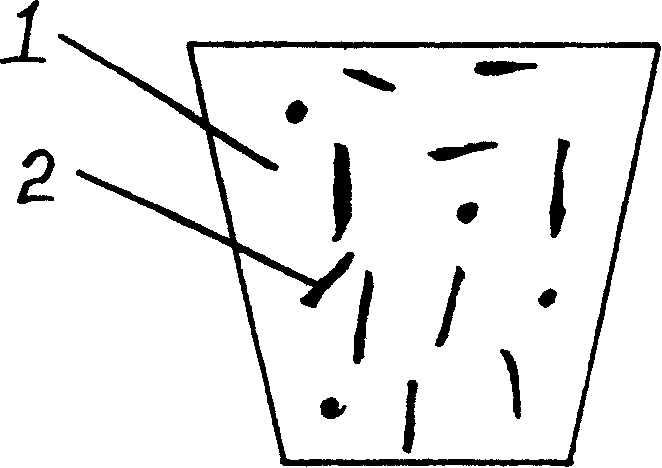

[0027] 4. Cast the aluminum-iron alloy liquid into a hexagonal trapezoidal mold, quickly add 35 kg of iron nuggets and iron particles into 100 kg of aluminum-iron alloy liquid, and make it completely immersed in the aluminum-iron alloy liquid;

[0028] 5. Demoulding after cooling and solidification to obtain an iron core aluminum-iron composite deoxidizer with a total weight of 135 kg.

Embodiment 2

[0030] 1. Take the following aluminum and iron raw materials: 95 kg of aluminum ingots, 5 kg of iron pellets, and 45 kg of iron bars;

[0031] 2. Heat 95kg aluminum ingot to 750-900℃ to melt it into molten aluminum;

[0032] 3. Add 5 kg of iron pellets to the above liquid aluminum, continue to heat up to 1000-1200°C, so that the iron pellets are completely melted in the molten aluminum, and stir evenly to obtain an aluminum-iron alloy liquid;

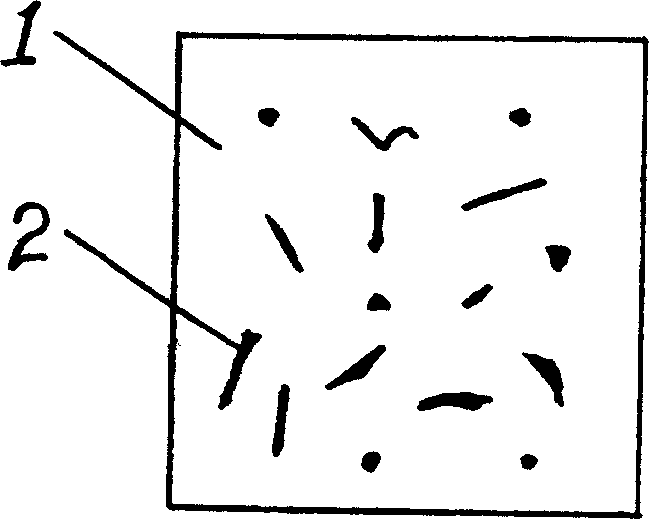

[0033] 4. Cast the aluminum-iron alloy liquid into a square trapezoidal mold, quickly add 45 kg of iron bars to 100 kg of aluminum-iron alloy liquid, and make it completely immersed in the aluminum-iron alloy liquid;

[0034] 5. Demoulding after cooling and solidification to obtain an iron core aluminum-iron composite deoxidizer with a total weight of 145 kg.

Embodiment 3

[0036] 1. Take the following aluminum and iron raw materials: 90 kg of aluminum ingots, 10 kg of iron wire, 40 kg of iron pellets and iron bars;

[0037] 2. Heat 90kg aluminum ingot to 750-900℃ to melt it into molten aluminum;

[0038] 3. Add 10 kg of iron wire to the above molten aluminum, continue to heat up to 1000-1200°C, so that the iron filings are completely melted in the molten aluminum, and stir evenly to obtain an aluminum-iron alloy liquid;

[0039] 4. Cast the aluminum-iron alloy liquid into a conical mold, quickly add 40 kg of iron pellets and iron bars to 100 kg of aluminum-iron alloy liquid, and completely immerse it in the aluminum-iron alloy liquid;

[0040] 5. Demoulding after cooling and solidification to obtain an iron core aluminum-iron composite deoxidizer with a total weight of 140 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com