Patents

Literature

63results about How to "High interfacial tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

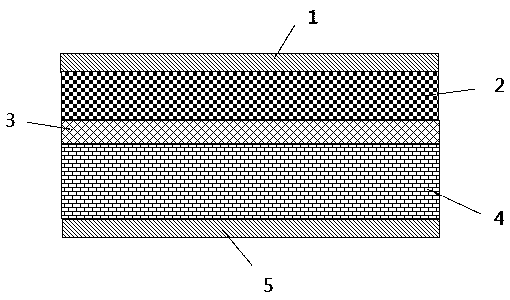

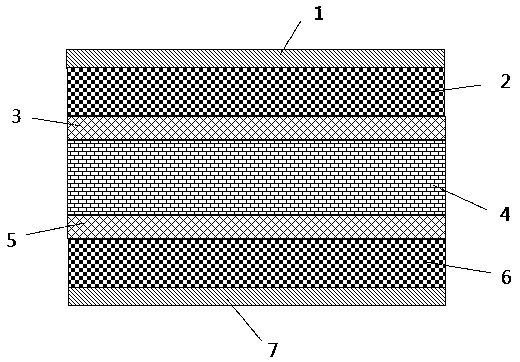

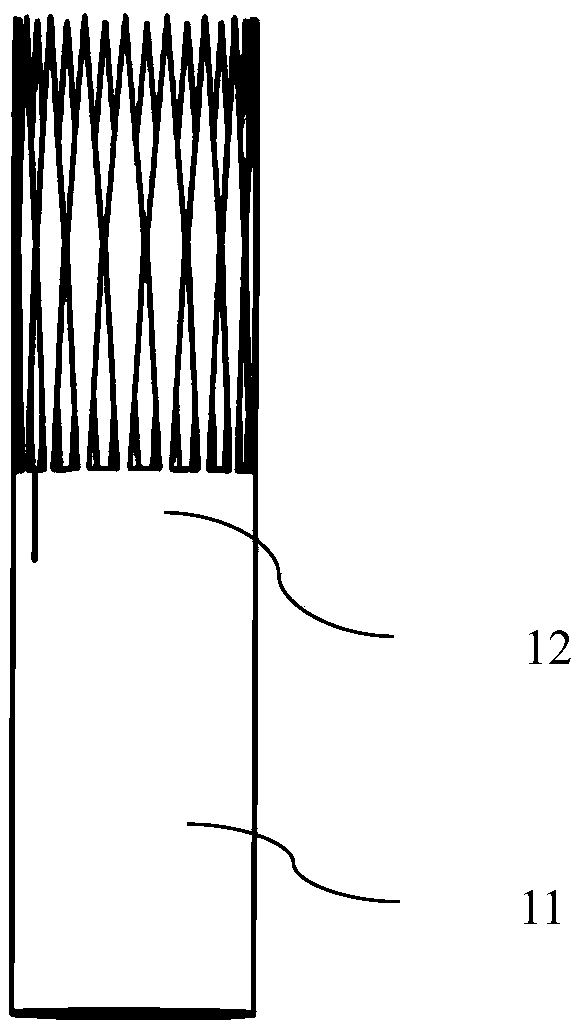

A preparation method of a ceramic coated separator for lithium ion batteries

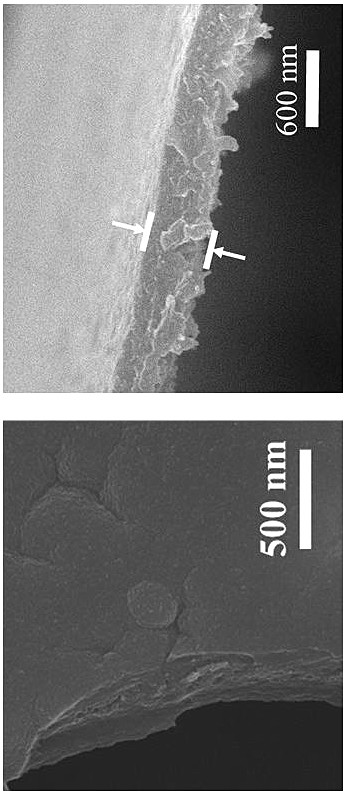

The invention discloses a preparation method of a ceramic coating separator for lithium ion batteries and belongs to the technical field of lithium ion battery separator production. The method involves a polymer porous base film, a polymer glue applied on one or both sides of the base film surface, a ceramic coating applied on the surface of the polymer glue, and a PVDF and its copolymer glue applied on the other side of the ceramic coating surface and the base film surface, wherein the PVDF and its copolymer glue are coated on the other side of the ceramic coating surface and the base film surface. The inorganic ceramic particles adopted by the invention are non-spherical and multi-particle, which can greatly improve the porosity of the ceramic coating, increase the lithium ion transit property, improve the liquid absorption rate of the diaphragm, and improve the rate performance and cycle life of the lithium ion battery. As the structure design of the ceramic coat diaphragm of the invention can increase the adhesive force of the ceramic coating and the polymer porous base membrane, the adhesive strength of the diaphragm and the positive and negative electrode sheets is improved,the problems of powder dropping and coating peeling off are effectively improved, the high-efficient automatic assembly of the lithium battery is realized, and the heat resistance and electrochemicalstability of the diaphragm are greatly improved.

Owner:HENAN FUSEN NEW ENERGY TECH

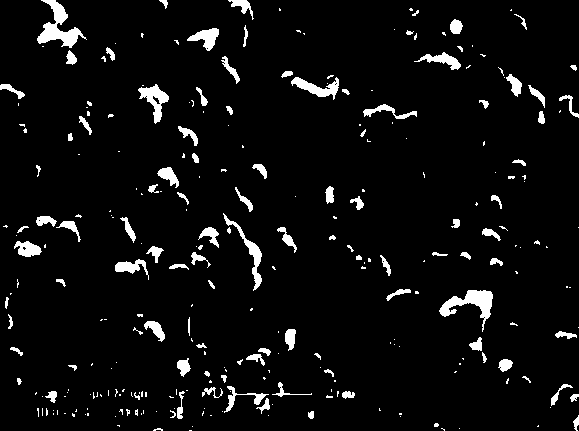

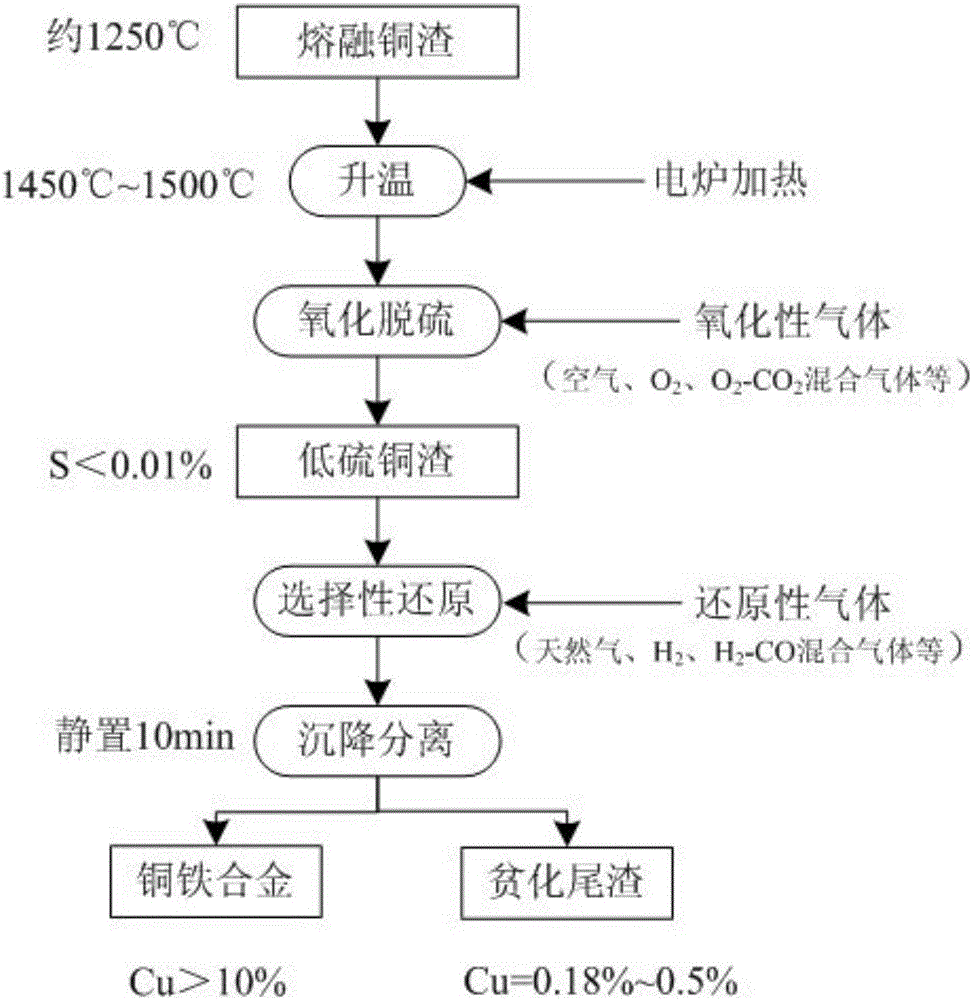

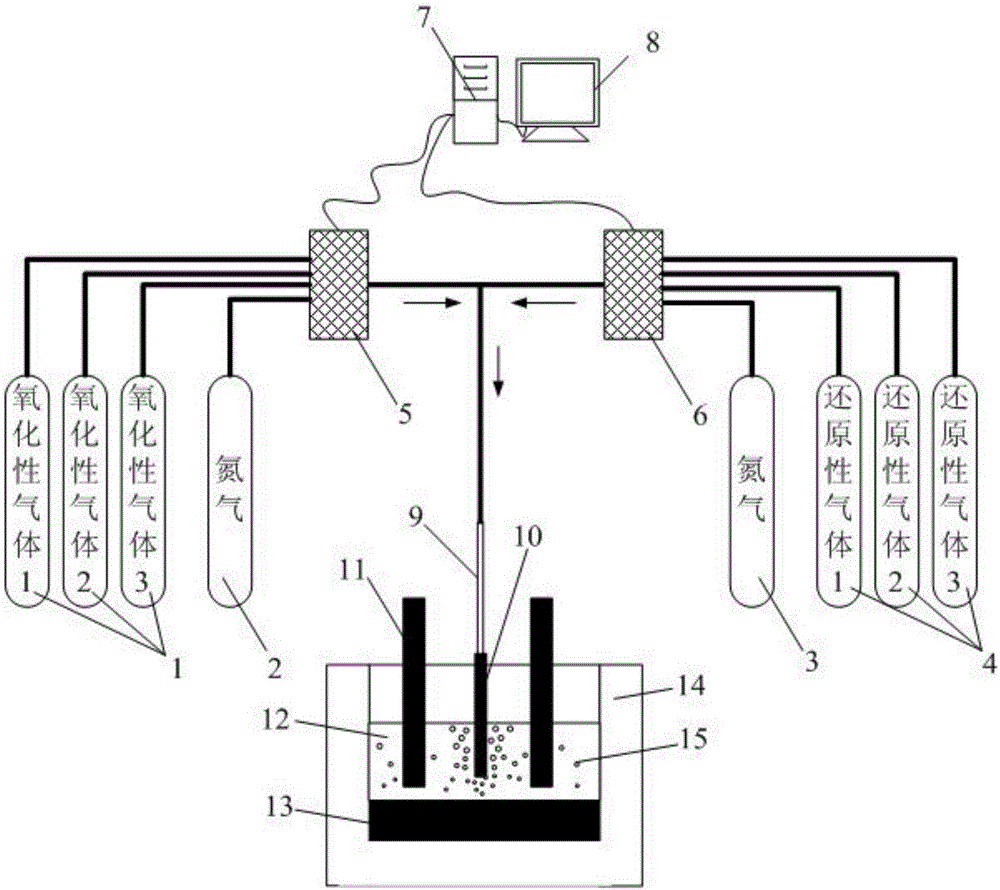

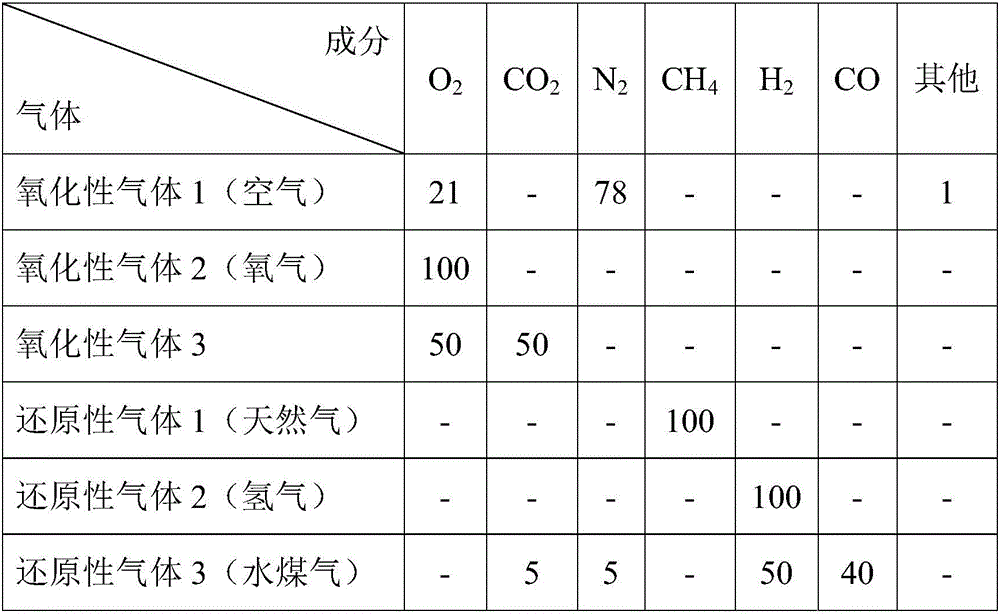

Method for realizing deep depletion on copper slag through multielement gas substep injection

ActiveCN106756062ARealize deep depletionComprehensive depletion results are excellentRotary drum furnacesCrucible furnacesLow copperMaterials science

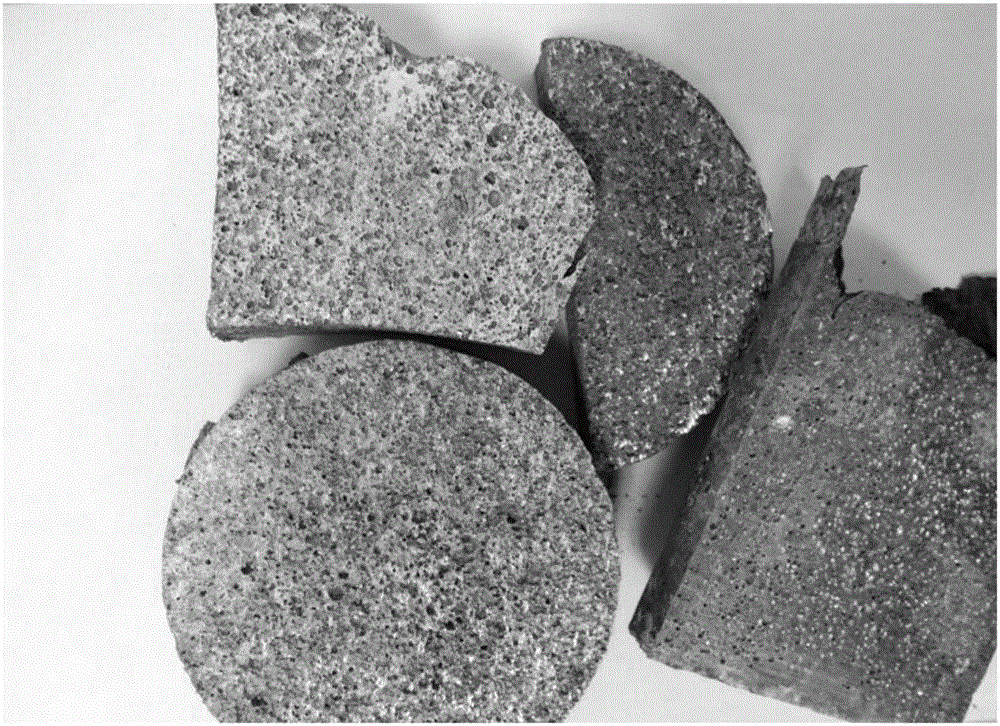

The invention provides a method for realizing deep depletion on copper slag through multielement gas substep injection. The method fully utilizes waste heat of molten copper slag, copper matte is converted into oxide through gasification desulphurization, then selective reduction is carried out to obtain copper iron alloy with higher copper content, the problem of copper slag depletion in a smelting process is solved, and low-sulfur low-copper depletion slag is produced, so that conditions are created for a follow-up iron extracting process, and the deep depletion on the copper slag is realized; the traditional matte-producing depletion process is abandoned, but a gasification desulphurization process is firstly carried out for converting the copper matte into the oxide, then the oxide is subjected to selective reduction by virtue of a reducing agent, so that a copper-iron alloy phase is obtained. Operation is simple, adaptability is strong, the method can be realized by modifying the original electric furnace, nickel slag similar to the copper slag in properties can be treated, and metal elements such as Cu, Ni, Co and Fe can be comprehensively recycled.

Owner:UNIV OF SCI & TECH BEIJING

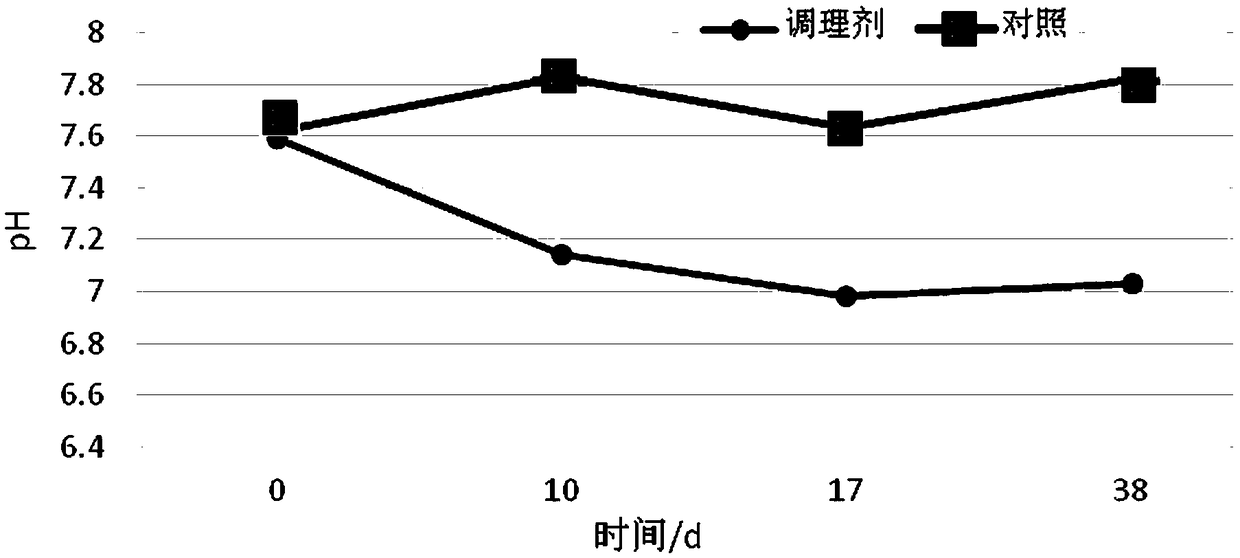

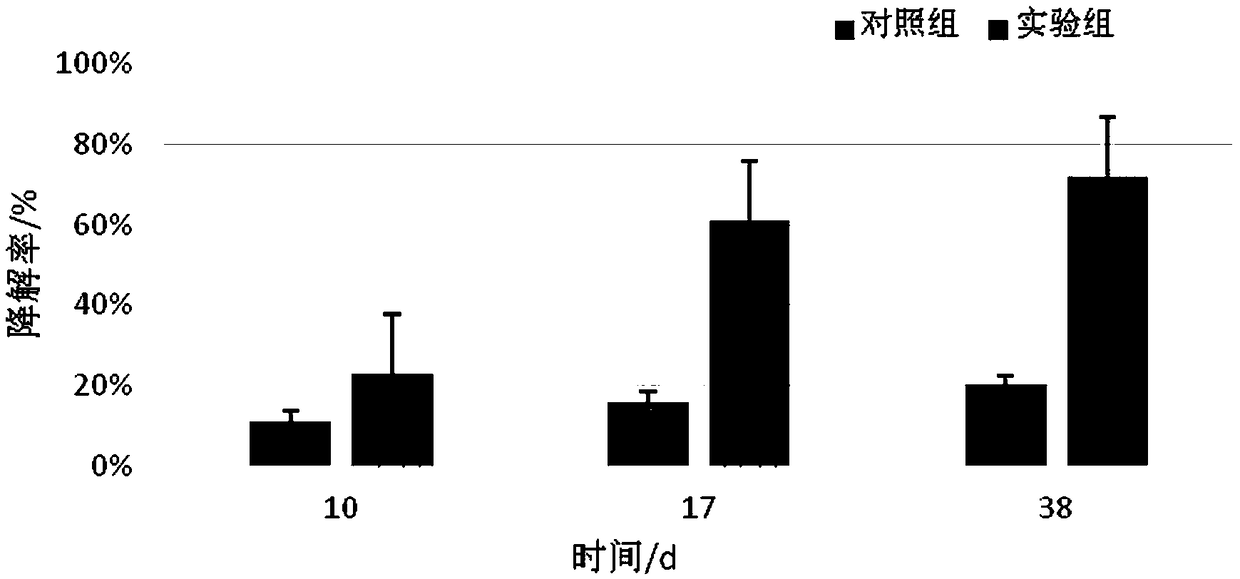

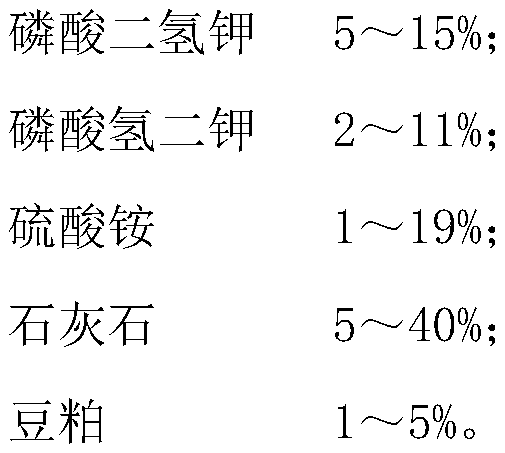

Conditioner for remediating organic contaminated soil by utilizing microbes

PendingCN108841392AEfficient degradationReduce compactionOther chemical processesOrganic fertilisersDipotassium phosphateFlora

The invention discloses a conditioner for remediating organic contaminated soil by utilizing microbes. The conditioner comprises the following components in percentage by mass: 5-20% of microbial flora fermentation liquor, 20-50% of an organic improver and 30-75% of a culture medium, wherein the microbial flora relates to 19 bacterial genera comprising acinetobacter, micrococcaceae, bacillus, candida, trichoderma and aspergillus; the organic improver is one or several of diatomite, humus, straws, charcoal, saw dust, bagasse and plant ash; the culture medium contains monopotassium phosphate, dipotassium phosphate, ammonium sulfate, limestone and bean pulp. The conditioner disclosed by the invention contributes to degrading growth and reproduction of the microbial flora of organic pollutants, and can achieve effects of regulating the pH value of the soil and nutrition-allocated proportion of carbon, nitrogen and phosphorus, effectively improving the composition and structure of the organic contaminated soil and avoiding the phenomenon that the ventilation volume of soil is reduced due to hardening, so that the organic contaminated soil is effectively remediated.

Owner:EAST CHINA UNIV OF SCI & TECH

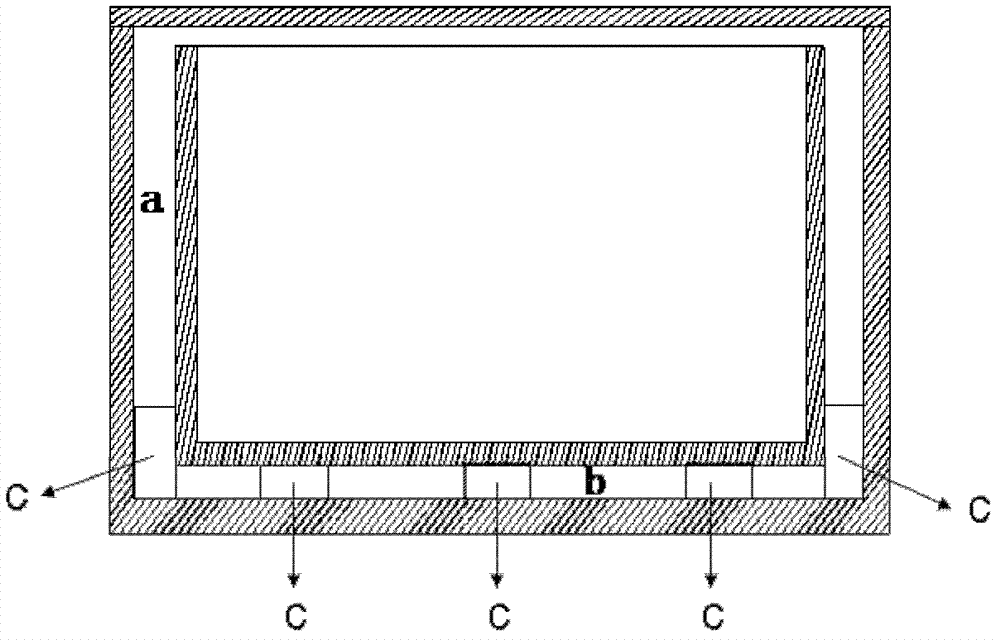

MgAlON combined aluminum magenisum permeable brick and preparation method thereof

The invention particularly relates to an MgAlON combined aluminum magenisum permeable brick and a preparation method of the MgAlON combined aluminum magenisum permeable brick. The technical scheme comprises the following steps of: taking 55-65 wt% of sintered corundum grains, 25-35 wt% of aluminum oxide fine powder, 2-10 wt% of metal aluminum powder and 2-10 wt% of fused magnesite fine powder as raw materials; then, additionally adding phenolic resin which is 2-6 wt% of the raw materials and grinding and agitating; carrying out mechanical pressing; drying under the condition of 180-220 DEG C for 12-24 hours; raising the temperature to 1500-1700 DEG C by a temperature-rising speed of 2-5 DEG C / min; and keeping the heat for 3-5 hours to prepare the MgAlON combined aluminum magenisum permeable brick. The prepared MgAlON combined aluminum magenisum permeable brick has the characteristics of high density, larger high-temperature strength, good thermal shock resistance, capability of being not wetted by liquid steel and strong corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH

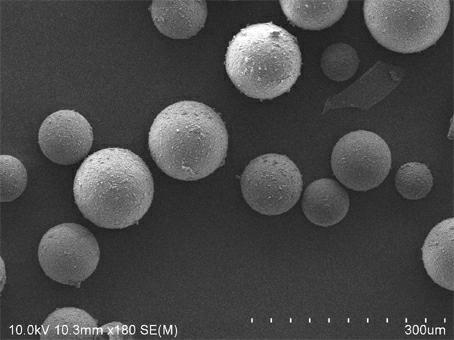

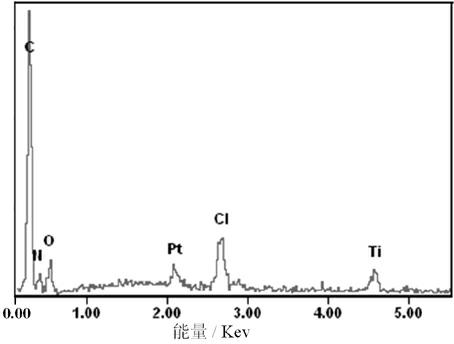

High-intensity urea-formaldehyde resin microcapsule and preparation method thereof

InactiveCN102167885ARegular shapeFlat surfaceMicroballoon preparationMicrocapsule preparationInorganic particleDistilled water

The invention relates to a high-intensity urea-formaldehyde resin microcapsule. Titanium dioxide or silicon dioxide inorganic nanoparticles with particle diameter of 10 to 50 nm are doped in the wall material of the microcapsule. A preparation method of the high-intensity urea-formaldehyde resin microcapsule comprises the following steps of: mixing urea and formaldehyde according to a molar ratio of the urea to the formaldehyde of 1:1.75; adjusting the pH value to 8.5 to 9.0; stirring at the constant temperature of between 70 and 75 DEG C for 1 hour; diluting by adding distilled water to obtain urea-formaldehyde prepolymer solution with mass concentration of 35 to 60 percent; taking 10 to 20 milliliters of the urea-formaldehyde prepolymer solution and adjusting the pH value to 4.0 to 4.2; reacting at the temperature of between 23 and 26 DEG C for 1 hour to obtain water-soluble urea-formaldehyde resin; dispersing the inorganic nanoparticles into an oil phase to prepare 0.04 to 0.2 mass percent of inorganic particle dispersion liquid; adding 40 milliliters of 7.3 mass percent of deionized water solution of a system modifier into the water-soluble urea-formaldehyde resin; adding 4.5 milliliters of inorganic particle dispersion liquid dropwise under stirring to form emulsion and then adjusting the pH value to 3.0 to 3.5; reacting at the temperature of between 23 and 26 DEG C for 1 hour; adding 0.3 to 3 grams of curing agent; heating the product to 45 to 50 DEG C; performing heat-preserving reaction for 2 hours; and performing suction-filtration and drying to obtain the urea-formaldehyde resin microcapsule, of which the wall material is doped with the inorganic nanoparticles.

Owner:SOUTHEAST UNIV

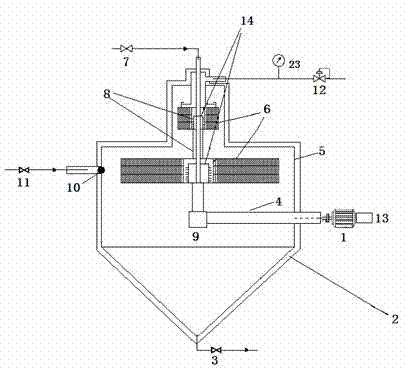

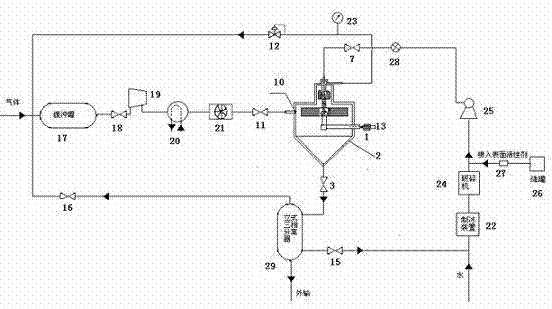

Supergravity hydrate synthesis device

ActiveCN103285781AUniform inflowHigh synthesis efficiencyChemical/physical processesBuffer tankThree-phase

The invention relates to the technical field of hydrate synthesis, storage and transportation and particularly relates to a supergravity hydrate synthesis device. The supergravity hydrate synthesis device comprises a cut-off valve, a one-way liquid valve, a nozzle, a one-way gas valve, a pressure regulating valve, a gas buffer tank, a compressor, a condenser, a turbine flowmeter, an ice maker, a pressure gauge, a pulping machine, a slurry pump, a surfactant storage tank, a Laval spraying valve, a mass flowmeter, a vertical three-phase separator and a supergravity reactor. The supergravity hydrate synthesis device adopts a supergravity technology for enhancing the heat transfer and mass transfer in a hydrate synthesis process, so that the reaction time is shortened, the equipment size decreases, the production cost is reduced, and a tapered outlet is formed so as to be helpful to the outflow of generated hydrates.

Owner:南通东湖国际商务服务有限公司

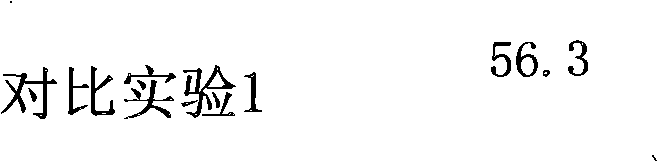

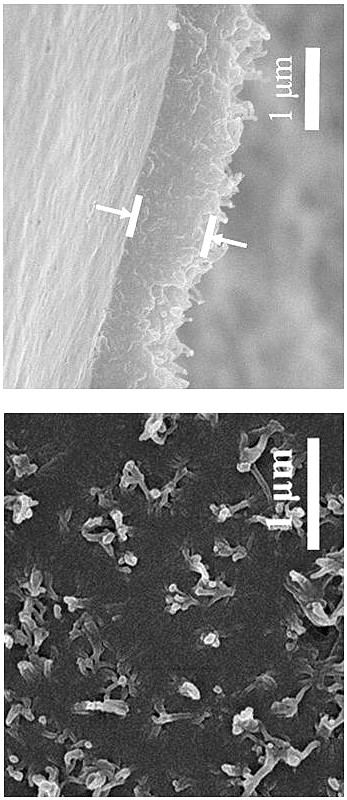

An aqueous ceramic/PVDF mixed coating slurry, a preparation method and an application thereof

ActiveCN109065804AEvenly dispersedReduce crystallinityFinal product manufactureCell component detailsWater basedHexafluoropropylene

A method for prepare an aqueous ceramic / PVDF mixed coat slurry comprises uniformly mixing high-purity water, perfluoroalkyl dispersant, tert-butyl hydrogen peroxide and acetone, continuously introducevinylidene fluoride and hexafluoropropylene gas to obtain aqueous PVDF emulsion; The ceramic material and the first dispersant are dispersed in deionized water, then thickener and adhesive, water-based PVDF emulsion and wetting agent are added, and the slurry is obtained after being uniformly mixed. The water-based ceramic / PVDF mixed coating slurry prepared by the invention is coated on a polyethylene diaphragm to obtain a wet film; A water-based ceramic / PVDF mix coating membrane is obtain by drying. The invention aims at remarkably improving the dispersion uniformity of ceramic / PVDF blend slurry, improving the uniformity of ceramic / PVDF blend coating separator coating, combining the characteristics of ceramic material and PVDF material, and remarkably improving the comprehensive performance of lithium ion battery separator.

Owner:湖南烁普新材料有限公司

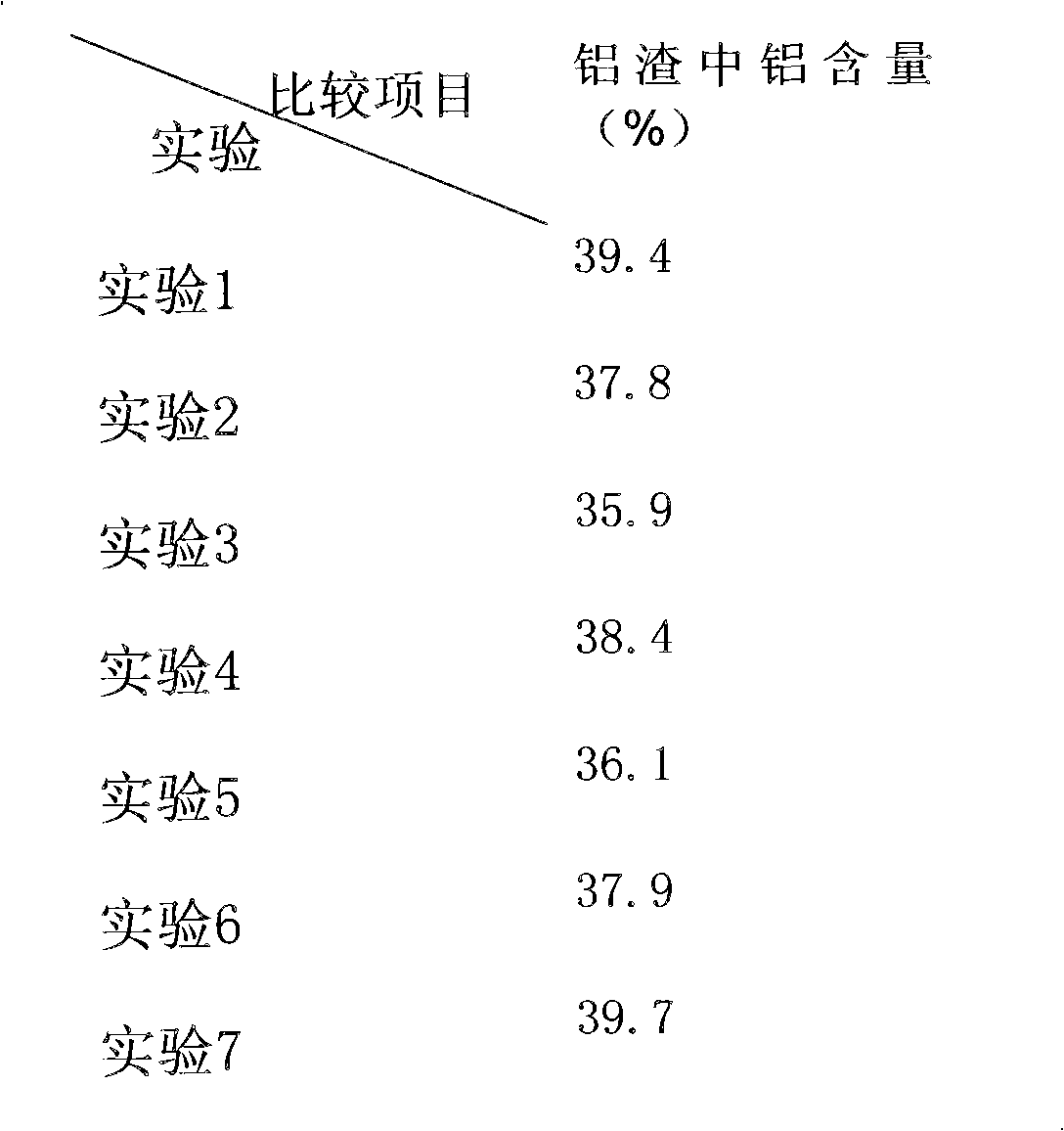

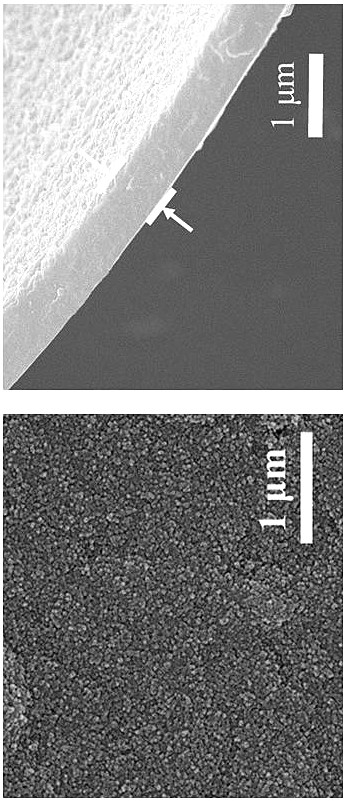

Aluminum-magnesium alloy slag removing agent, method for producing aluminum-magnesium alloy ingot and aluminum-magnesium alloy ingot

The invention discloses an aluminum-magnesium alloy slag removing agent, a method for producing an aluminum-magnesium alloy ingot and the aluminum-magnesium alloy ingot, and belongs to the field of chemistry. The aluminum-magnesium alloy slag removing agent contains the following components: KR1, MgR22 and K3A1R36, wherein R1, R2 and R3 are an element in halogens respectively. The aluminum magnesium alloy slag removing agent claimed by the invention does not contain sodium salt, and can prevent combustion of aluminum slag and increase the slag removing capability of a solvent and the aluminum and slag separation effect.

Owner:SICHUAN XINXING ALUMINUM IND

Method for preparing high-crystallinity covalent organic framework film by using ionic liquid-water interface

PendingCN113603912AImprove film qualityAvoid pollutionSemi-permeable membranesPtru catalystP-Toluenesulfonic acid

The invention discloses a method for preparing a high-crystallinity covalent organic framework membrane by using an ionic liquid-water interface. The method comprises the following steps of: dissolving an aldehyde monomer in a hydrophobic ionic liquid to obtain a solution A; dissolving an amine monomer and an acid catalyst p-toluenesulfonic acid in deionized water to obtain a solution B; transferring the solution A into a reactor, adding deionized water to the surface of the solution A, layering, adding the solution B to the upper part of the deionized water layer, and performing a reaction for more than 3 days in the reactor under the condition of still standing at room temperature, so as tosynthesize the covalent organic framework membrane by using a double-diffusion control mechanism that the hydrogen-bond interaction of the acid catalyst and the amine monomer and the high viscosity of hydrophobic ionic liquid are utilized and the diffusion rates of the two monomers are limited at the same time. The covalent organic framework membrane prepared by the method has very high crystallinity, the specific surface area of themembrane is increased by 4 times compared with that of a covalent organic framework membrane synthesized on a traditional dichloromethane-water interface, and the solvent flux is also increased by 2 times under the condition that dye interception is not influenced.

Owner:HENAN NORMAL UNIV

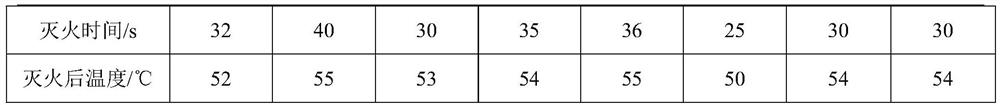

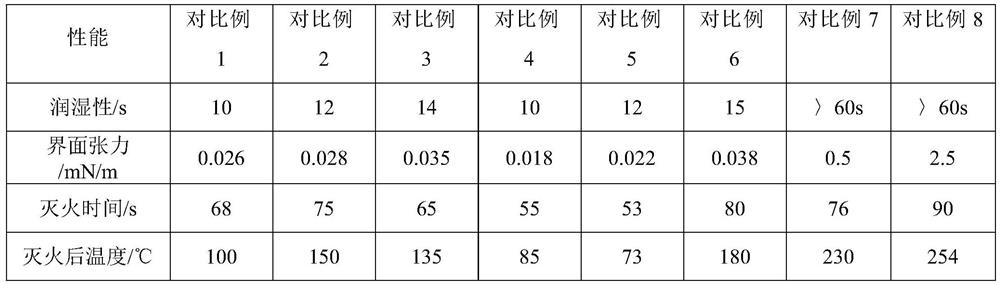

Environment-friendly water-based fire extinguishing agent for fire protection

PendingCN112675469AReduce interfacial tensionImprove interfacial tensionFire extinguisherPhosphoric Acid EstersPhosphate

The invention belongs to the technical field of fire-fighting foam, and discloses a fire-fighting environment-friendly water-based fire extinguishing agent. The fire extinguishing agent is prepared from the following raw materials in percentage by weight: 15 to 40 percent of fatty acid amide, 5 to 10 percent of phosphate, 5 to 10 percent of foaming agent, 3 to 5 percent of fatty alcohol, 1 to 3 percent of pH regulator, 0.5 to 0.8 percent of preservative, 0.2 to 0.5 percent of stabilizer, 10 to 15 percent of organic solvent and the balance of water. According to the invention, fatty acid amide is used as a main surfactant and cooperates with other assistants, so the prepared fire extinguishing agent has the advantages of low interfacial tension, high wettability and high foaming and fire extinguishing speed; phosphate is added into the fire extinguishing agent, so that the flame retardance can be improved, the wettability of the system is improved, and the foaming property and the fire extinguishing property of the system are promoted to a certain extent; the addition of the fatty alcohol can increase the emulsifying property of the system, reduce the interfacial tension of oil and water and reduce the height of an emulsifying layer of mixed oil and water; the emulsifying effect is promoted by controlling the addition amount of the fatty alcohol, but the height of an oil-water mixing layer is not increased, and fire extinguishment and field treatment after fire extinguishment are facilitated.

Owner:四川科宏达集团有限责任公司

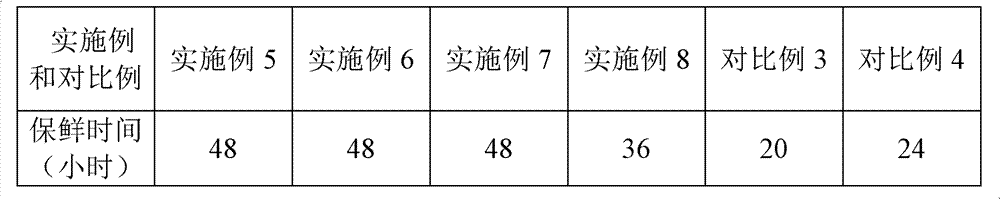

Fresh keeping container and food fresh keeping method

Owner:BEIJING RECHSAND SCI & TECH GRP

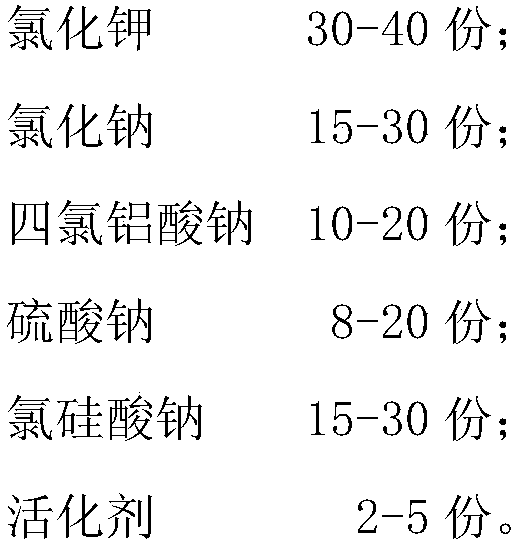

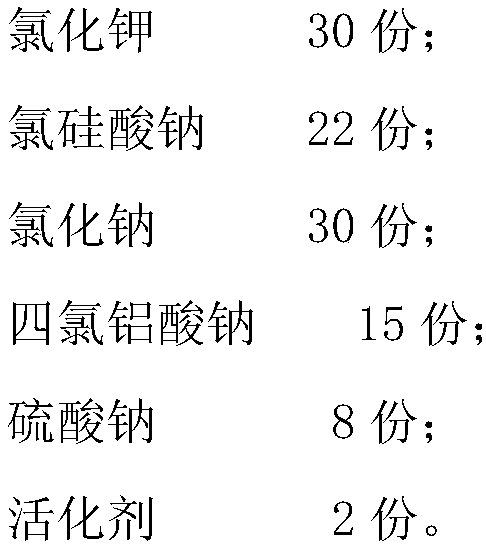

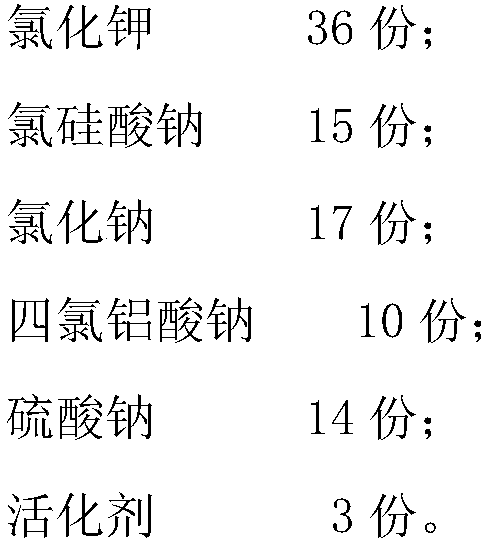

Refining agent for metal smelting, preparation method and refining technology

InactiveCN108660331APromote decompositionImprove refining efficiencyLead smeltingAtmospheric pollution

The invention relates to the technical field of aluminum and aluminum alloy purifying and refining treatment, in particular to a refining agent for metal smelting, a preparation method and a refiningtechnology. The refining agent for metal smelting aims to remove impurities of molten aluminum in the aluminum alloy refining process, so that the product quality is improved, and atmospheric pollution is avoided. The refining agent for metal smelting comprises, by weight, 30-40 parts of potassium chloride, 15-30 parts of sodium chloride, 10-20 parts of sodium tetrachloroaluminate, 8-20 parts of sodium sulfate, 15-30 parts of chloride sodium silicate and 2-5 parts of activating agent. According to the refining agent for metal smelting, the activating agent is added to the refining agent, the activating agent can promote sodium tetrachloroaluminate in the refining agent to decompose and reduce the interfacial tension between the refining agent and oxide inclusion at the same time, so that the oxide inclusion can smoothly float on the surface of the melt and then is removed, and therefore the product quality is improved.

Owner:湖北新金洋资源股份公司

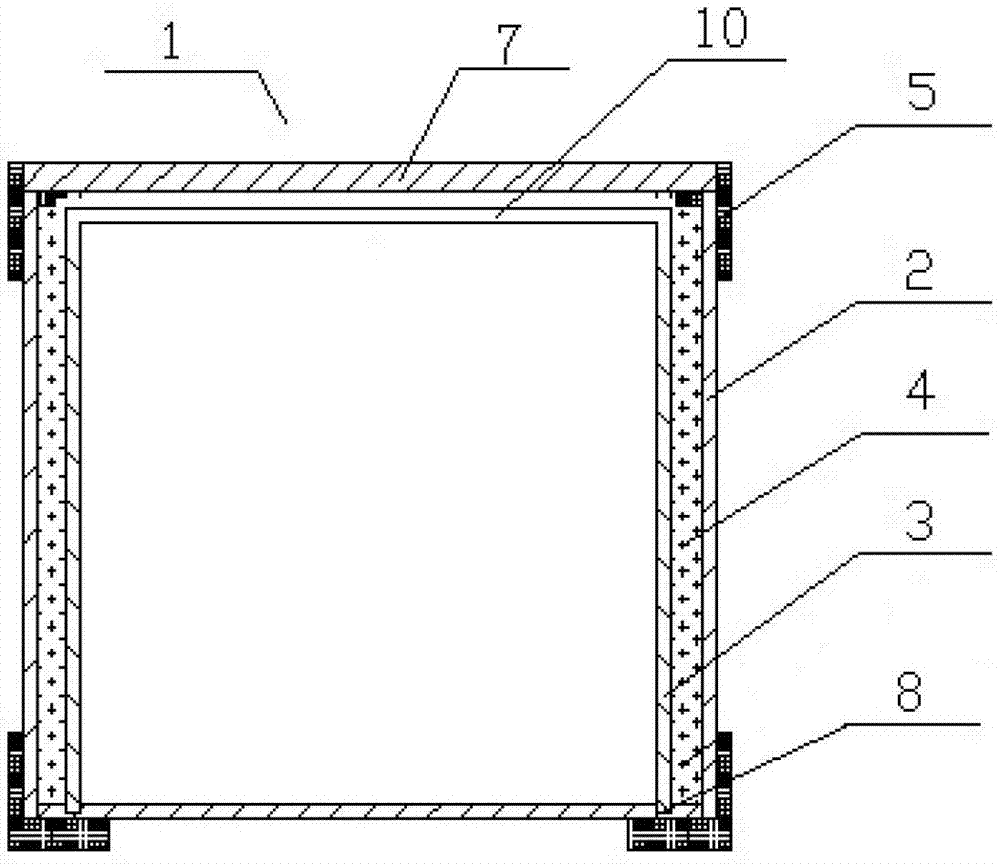

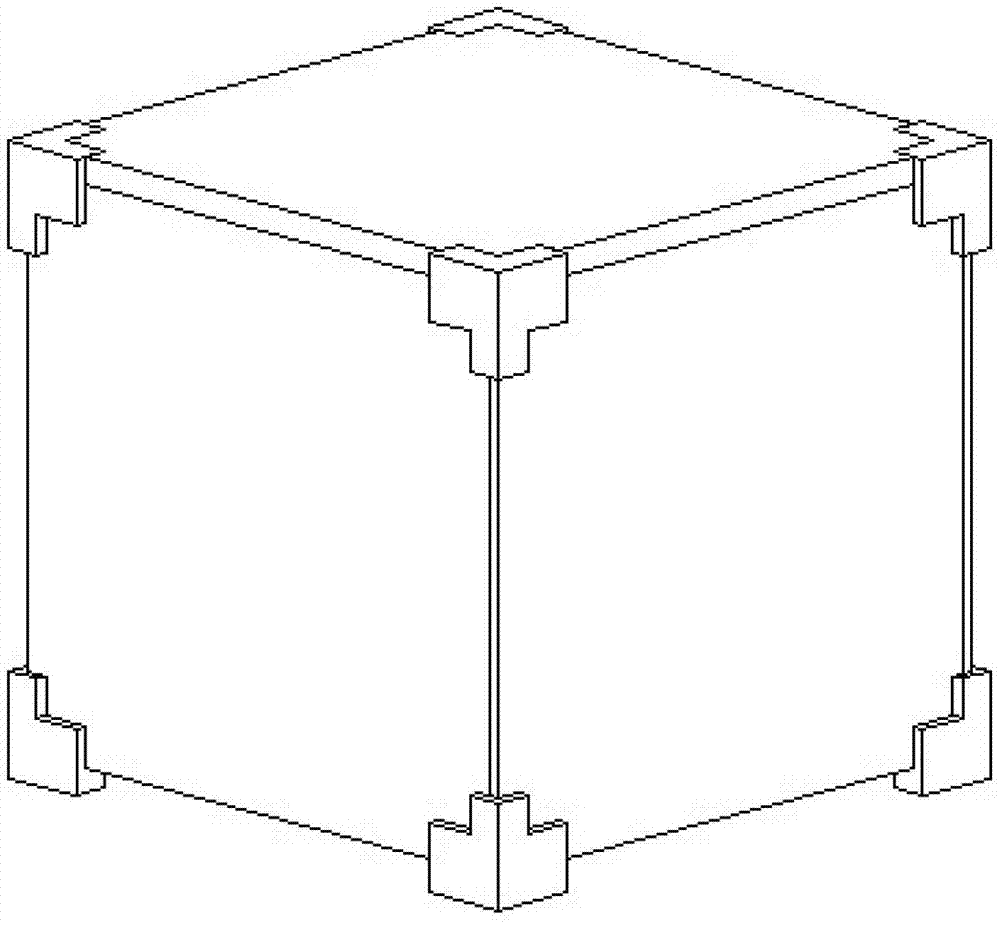

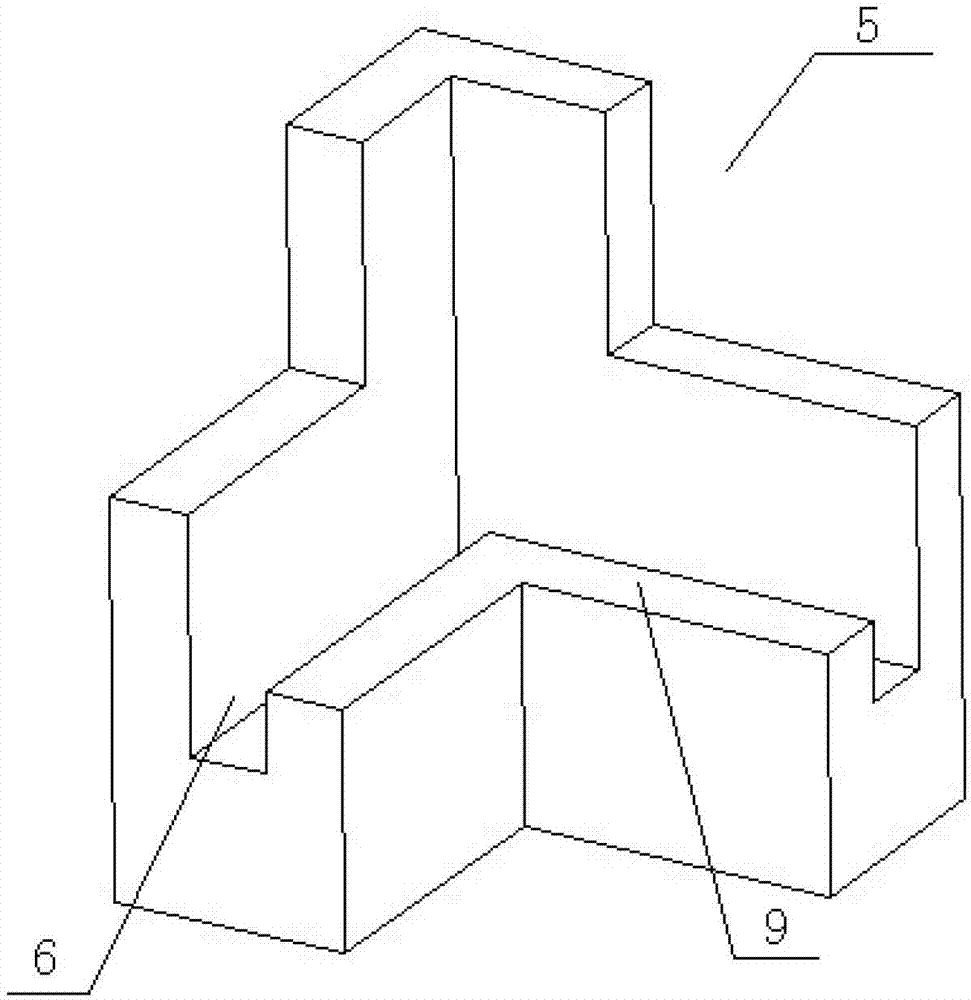

Air-permeable moisture-proof container capable of being assembled

ActiveCN103171814AGuaranteed breathabilityExtended shelf lifeFlexible coversWrappersDrying AgentsMoisture

The invention provides an air-permeable moisture-proof container capable of being assembled. The air-permeable moisture-proof container capable of being assembled comprises an air-permeable moisture-proof container body and a container cover which are matched. The air-permeable moisture-proof container body comprises a bottom surface and a lateral wall, wherein the lateral wall is in a double-layer structure and comprises an inner-layer lateral wall and an outer-layer lateral wall, a hollow cavity used for containing drying agent is formed among the inner-layer lateral wall, the outer-layer lateral wall and the bottom surface, the inner-layer lateral wall is formed by inner-layer freshness preservation boards in an assembly mode, the outer-layer lateral wall is formed by outer-layer freshness preservation boards in an assembly mode, and the air-permeable moisture-proof container body is formed among the inner-layer freshness preservation boards, the outer-layer freshness preservation boards and the bottom surface in an assembly mode. The air-permeable moisture-proof container is capable of being installed on site according the scale requirements, and has a good food freshness preservation effect.

Owner:BEIJING RECHSAND SCI & TECH GRP

Solvent for high-temperature melting heat-resistant aluminium alloy

The invention was involved in an agent of fusion, especially for the agent of fusion for smelting heat-resisting aluminum alloy at high temperature. The agent of fusion consist of 60%-80% Na3AlF6, 5%-10% NaCl and 10%-20% CaF2. It had strong ability of adsorption, solution power and formation of slag. Compared with metal melt, the agent of fusion had rather large gravity difference. It was easy to separate the agent of fusion from metal for there was large boundary tension between metal melt and it. The agent of fusion had strong chemical stability and heat stability, so there was no corrosive action to metal and lining or no harmful gas and impurity. The agent of fusion with lower melting point and suitable viscosity, little hygroscopic ability and low vapor pressure was convenient to produce with cheap price. During the practice, the refine effect of slag removal and degasification were improved and metal oxidation, air-breathing and volatilization and the interaction of metal and lining were decreased so that the alloy technology was improved. The extensibility of alloy treated by antiflux was improved by 30% compared with the untreated alloy.

Owner:CENT SOUTH UNIV

Anti-oxidizing nanometer mixed oil with low cost and preparation method thereof

ActiveCN109054948ALowering the freezing pointHigh interfacial tensionLubricant compositionOxidation resistantAntioxidant

The invention discloses an anti-oxidizing nanometer mixed oil with low cost. The anti-oxidizing nanometer mixed oil is prepared from the following components in parts by weight: 30 to 50 parts of mineral oil, 15 to 20 parts of rapeseed oil, 4 to 8 parts of olive oil, 6 to 12 parts of castor oil, 15 to 30 parts of anhydrous ethanol, 1 to 5 parts of composite antioxidant, 1 to 3 parts of nanometer SiO2 (silicon dioxide) particle, 1 to 3 parts of nanometer ZnO (zinc oxide) particle, 1 to 3 parts of nanometer A12O3 (aluminum oxide) particle, 1 to 3 parts of polymethacrylate pour point depressant,0.5 to 2 parts of passivating agent, 0.5 to 1 part of viscosity regulator, and 0.5 to 1 part of metal chelating agent. The anti-oxidizing nanometer mixed oil has the advantages that the better anti-oxidizing property is realized, the oxidizing speed of the mixed oil is delayed, and the service life is prolonged; the pour point is smaller, and the use requirement under the low-temperature environment is met; the good electric property and physical-chemical property are realized, and the cost is low.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +3

Preparation method of flat acrylic fiber

ActiveCN110835786AImprove hydrophobicityImprove flatnessArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceSpinning

The invention relates to a preparation method of flat acrylic fiber. The preparation method is characterized by sequentially including following steps: spinning, coagulating, and forming: extruding polymer dope of 10-13.5wt% in polyacrylonitrile copolymer content into coagulating bath by a rectangular-hole spinneret plate after being treated specially, and forming primary fiber through double diffusion coagulating; drying for densification after water washing and drafting, and performing heat setting; oiling, winding, and drying: subjecting fiber after being treated thermally to soak-oiling and winding sequentially to endow with processability after spinning to obtain the flat acrylic fiber. Compared with existing rectangular-hole spinneret plates, the preparation method has the advantagesthat the surface of a tantalum metal spinneret plate is improved through nitriding and siliconing, in this way, temperature difference of the polymer dope in the spinneret plate and the coagulating bath is increased from delta 45-50 DEG C before treatment to delta 55-60 DEG C, contact angle of the dope at an orifice outlet is increased by 30 degrees, rheological performance of the dope is improved, and production stability and quality improvement of the flat fiber are ensured.

Owner:CHINA PETROLEUM & CHEM CORP

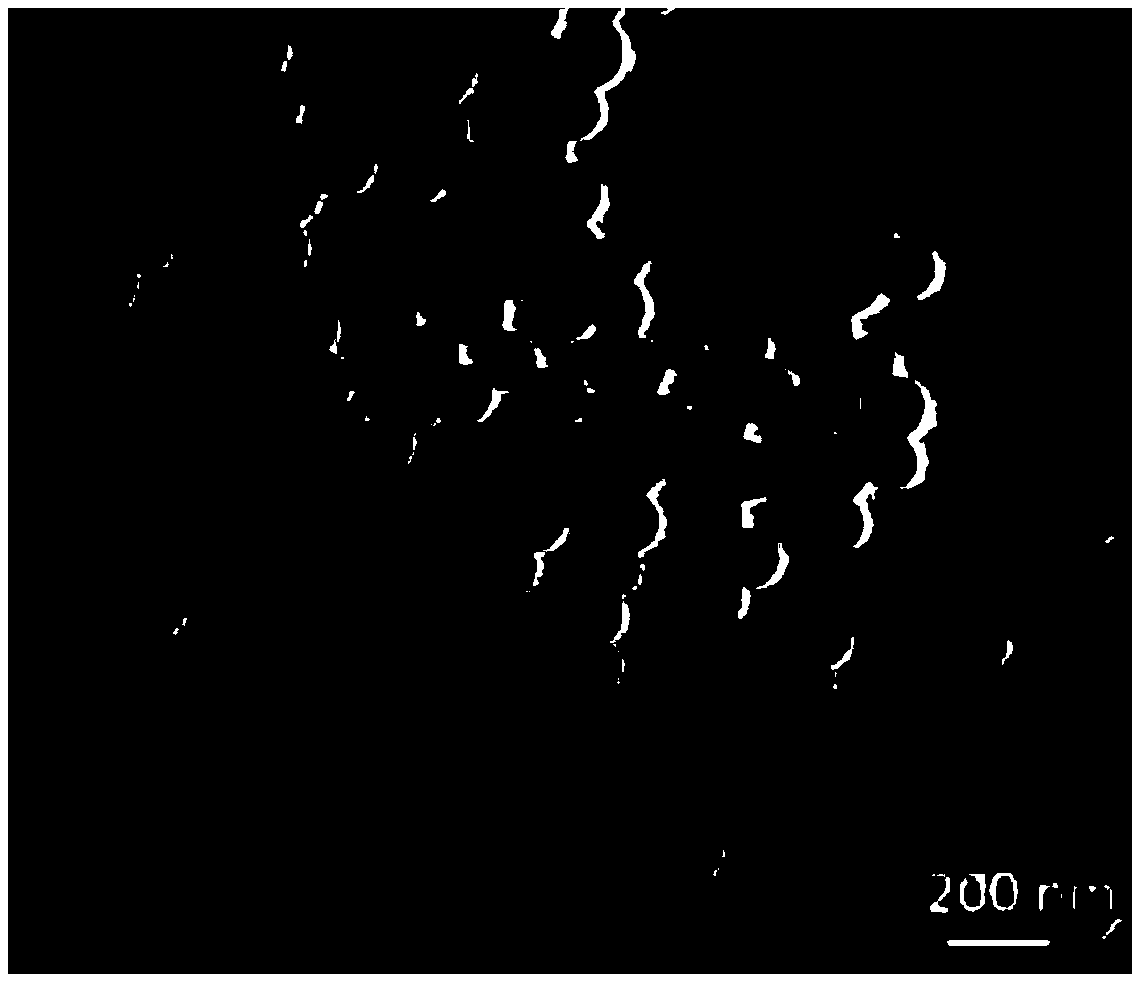

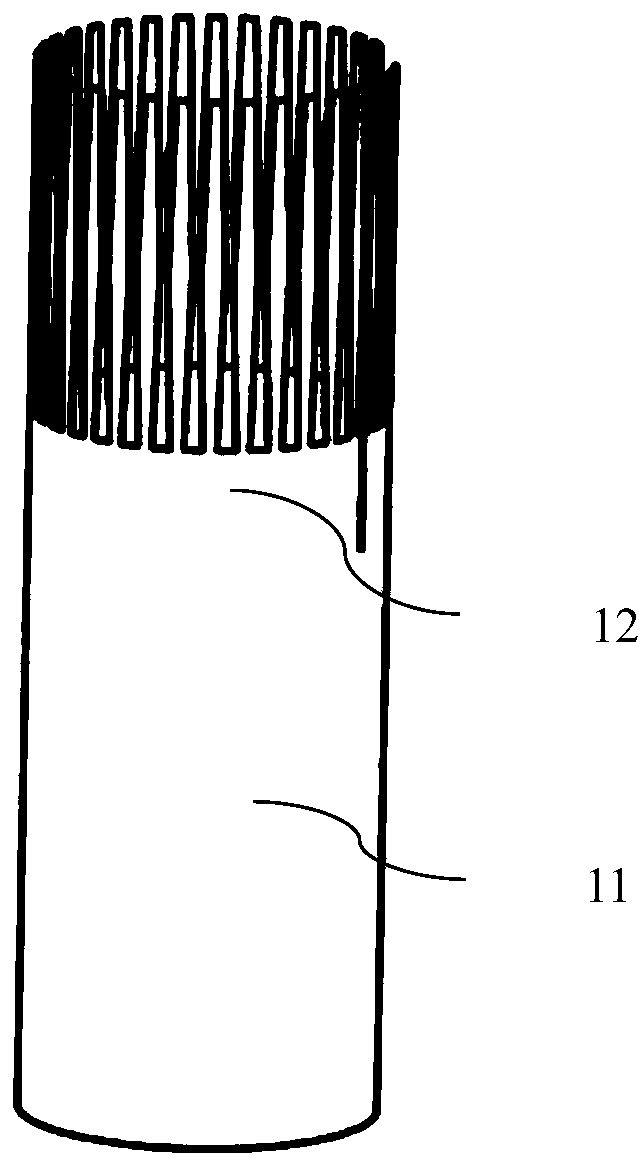

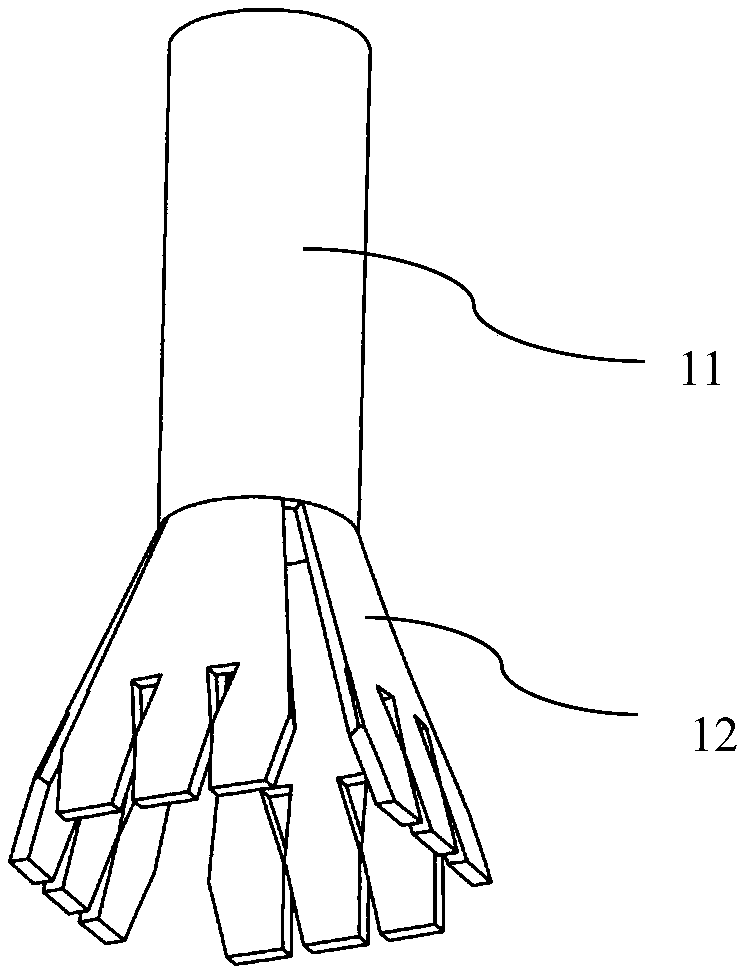

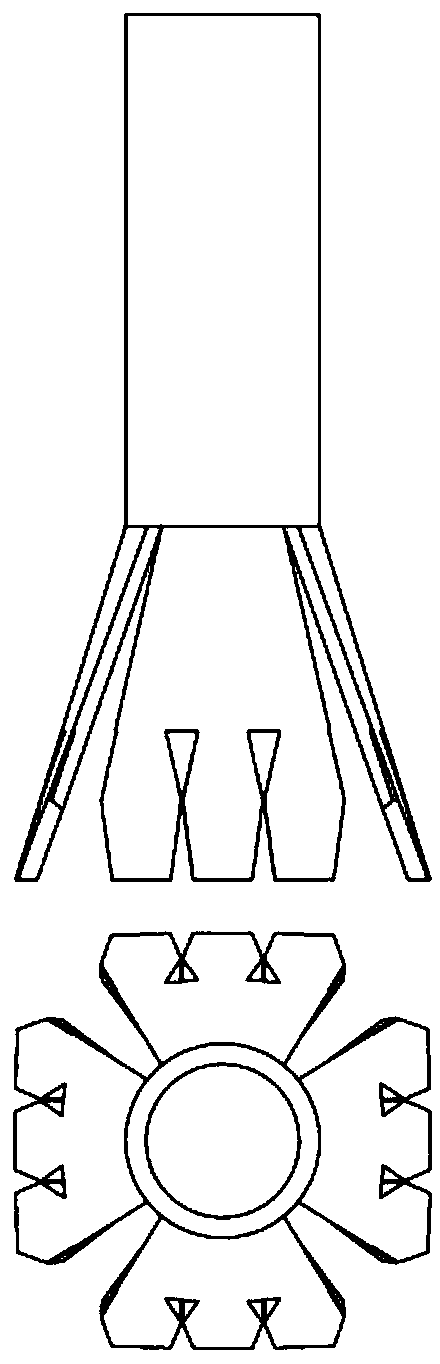

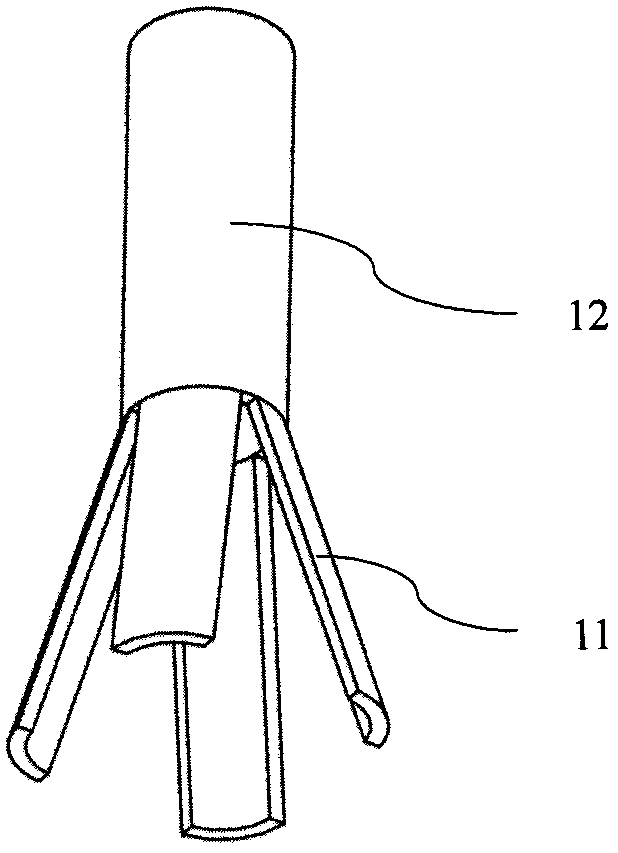

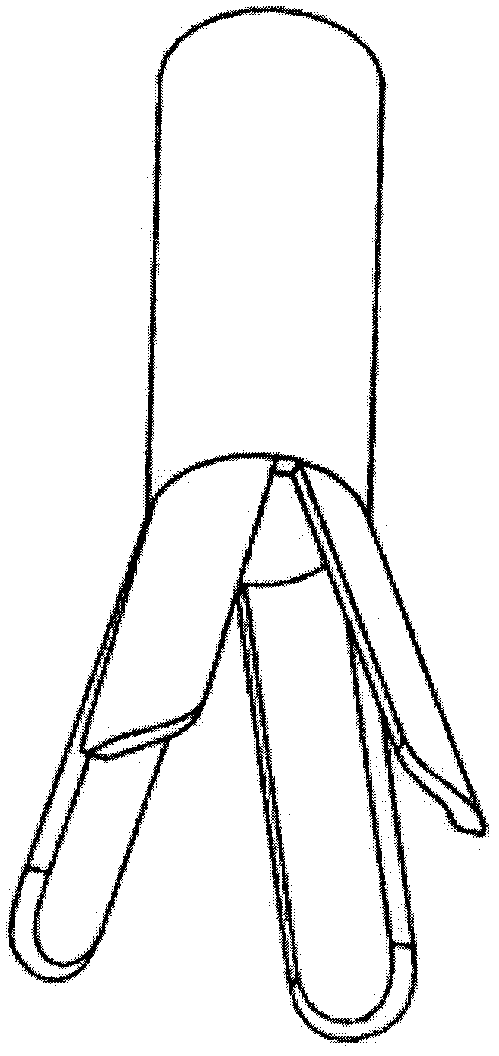

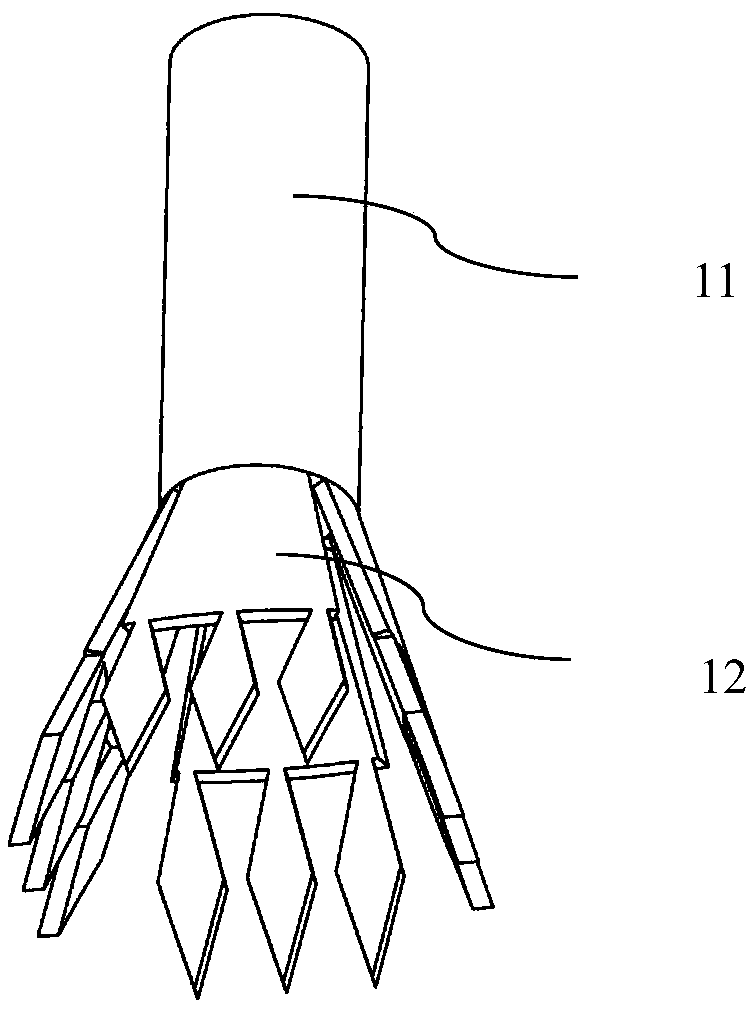

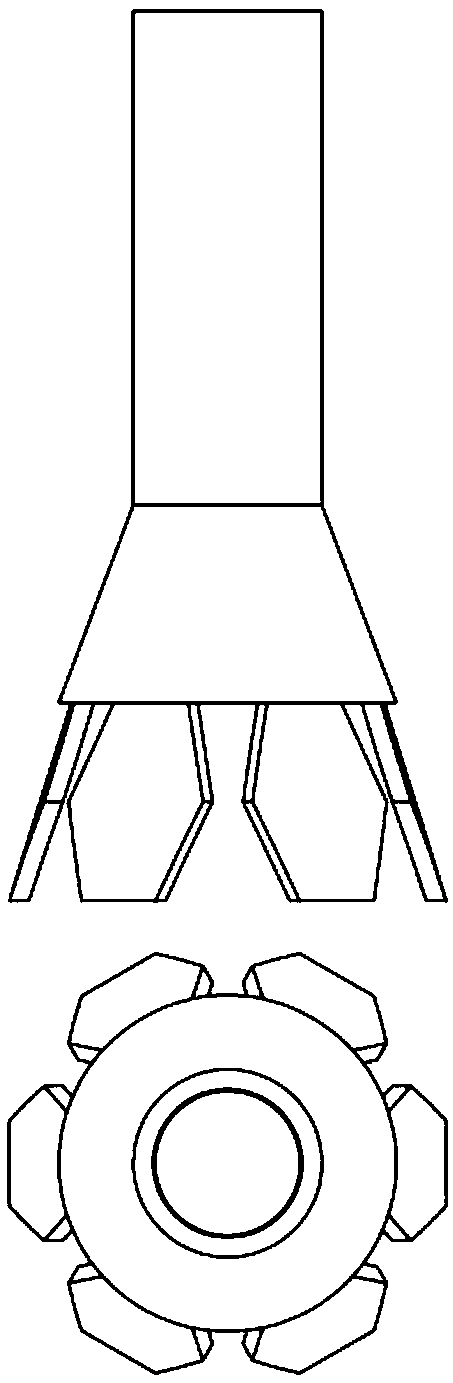

Radial electrospinning nozzle based on differential polygonal blades

InactiveCN108893787AHigh interfacial tensionNot volatileFilament/thread formingHigh concentrationElectrospinning

The invention relates to a radial electrospinning nozzle based on a differential polygonal blade, belonging to the technical field of nanofiber preparation, which is composed of a cylindrical tube anda radial spinneret with a differential polygonal blade at the top. The radial spinneret is composed of a plurality of radial blades with the same structure evenly distributed along the circumference,a plurality of differential polygonal blades are equally spaced at the top of each radial blade, the radial spinneret is located at the upper or lower part of the cylindrical tube, and the inner diameter of the joint is equal, and the connection is tight and smooth, so that the barrier-free transport of the electrospinning fluid can be realized. The radial spinneret is composed of a plurality ofradial blades with the same structure uniformly distributed along the circumference. The radial electrospinning nozzle based on the differential polygon blade has a large inner diameter, is favorablefor avoiding the clogging problem, and can electrospin the high-concentration spinning solution; The radial spinneret can stabilize the droplets and produce multiple spinning jets, resulting in high spinning yield. The tubular structure can realize sealed and controllable liquid supply, and the solvent is not easy to volatilize. Differential polygon blades with tips can generate higher field strength and reduce energy consumption.

Owner:WUHAN TEXTILE UNIV

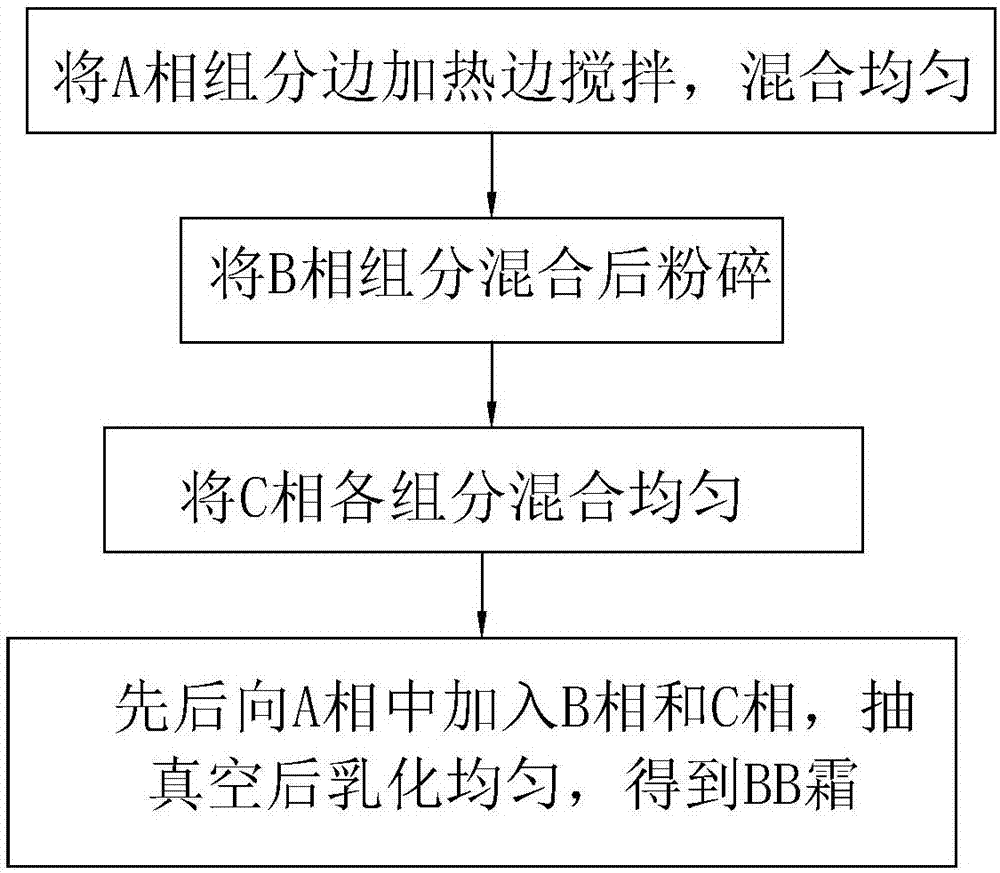

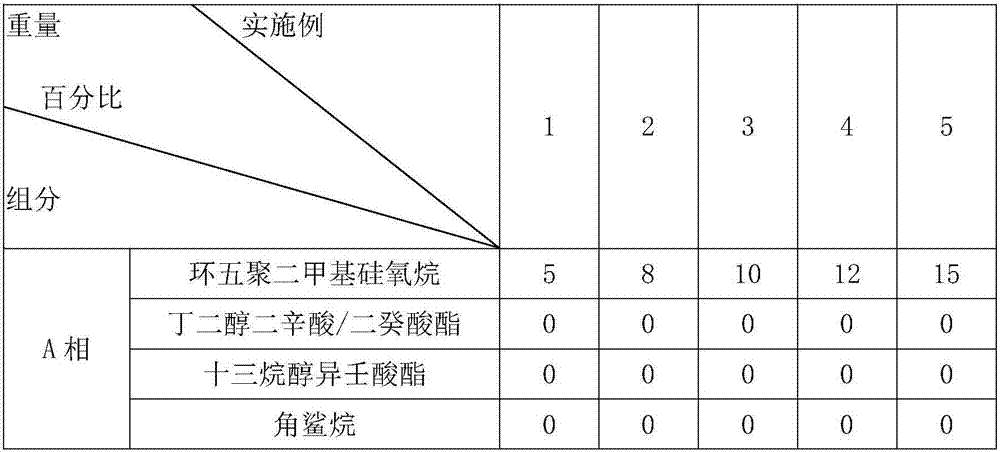

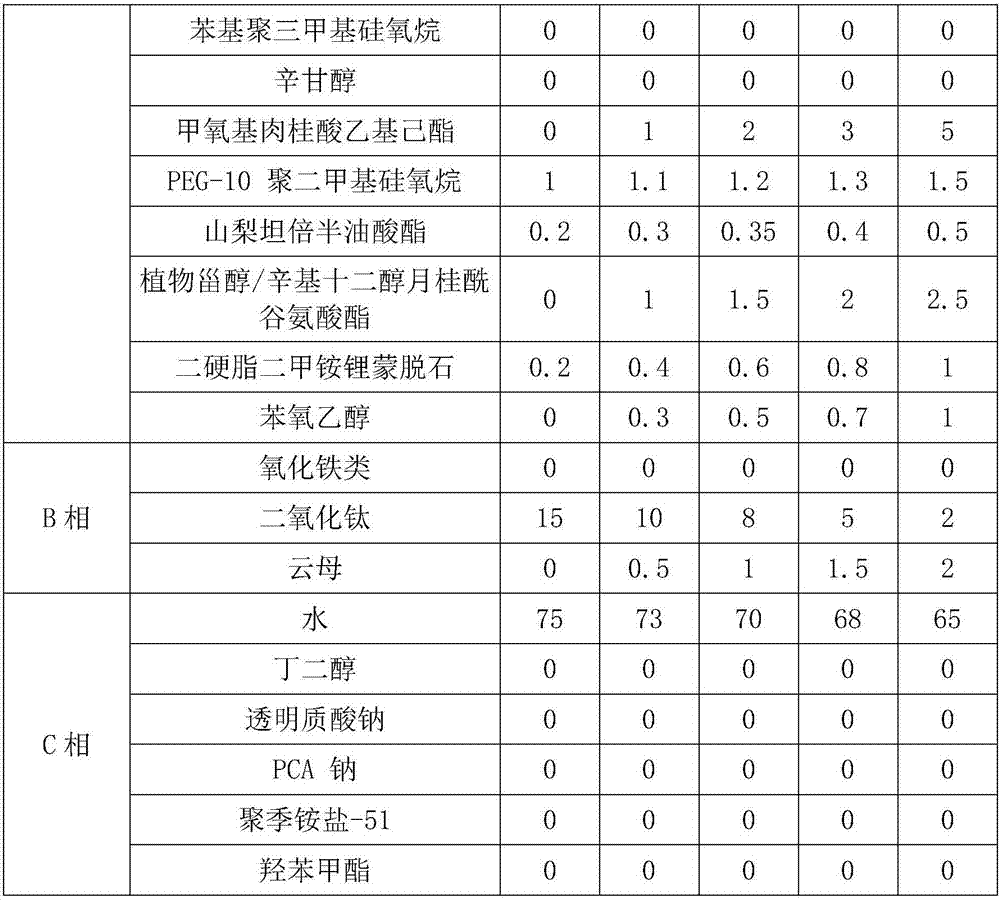

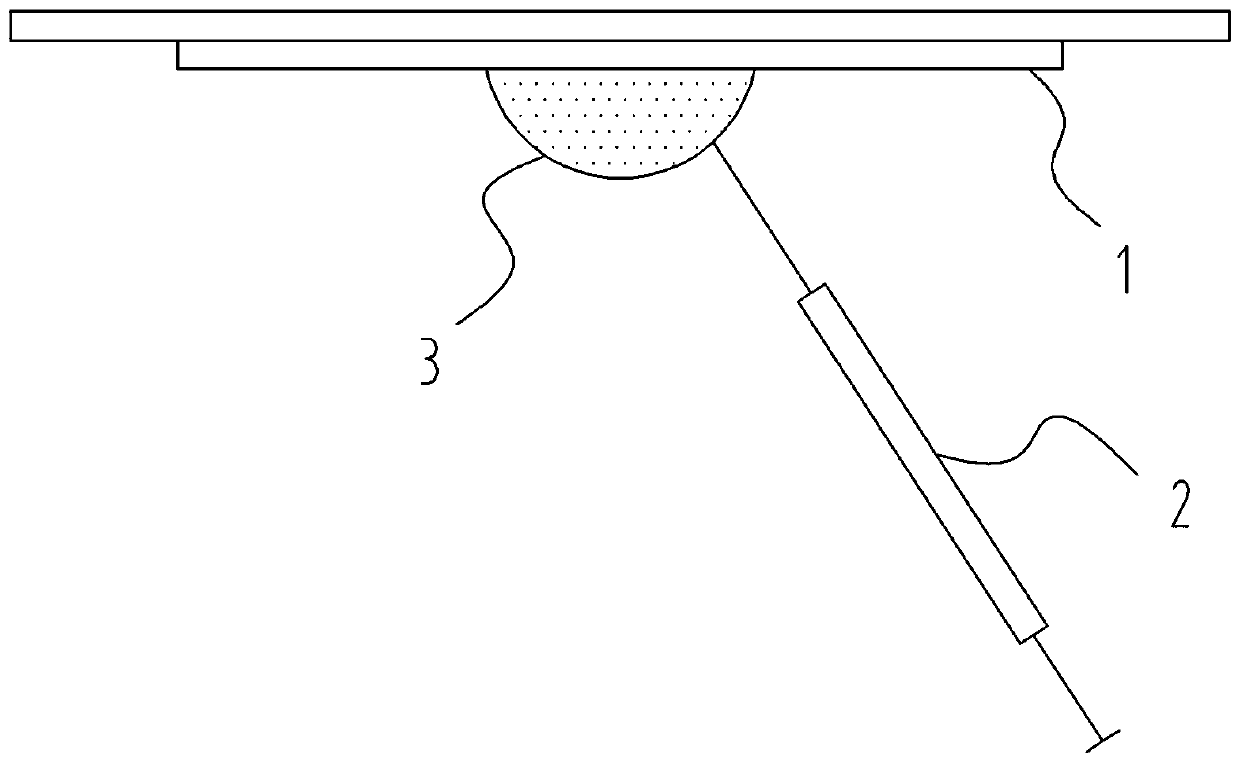

BB cream and preparation method thereof

InactiveCN107456403AUV protectionImprove absorption rateCosmetic preparationsMake-upUltrasonic emulsificationDimethyl siloxane

The invention discloses a BB cream and a preparation method thereof, relating to the technical field of cosmetics. The BB cream contains the following components in percentage by weight: 5%-15% of cyclopentasiloxane, 0-5% of a sun-screening agent, 1%-1.5% of PEG-10 polydimethylsiloxane, 0.2%-0.5% of sorbitan sesquioleate, 0-2.5% of phytosterol / octyldodecanol lauroyl glutamate, 0.2%-1% of a thickener, 0-1% of a preservative, 2%-15% of a coloring agent, 0-2% of a filling agent and 65%-75% of water. By utilizing an ultrasonic emulsification process, the use amount of an emulsifying agent is reduced, the water resistance and oil resistance of the product are enhanced, the makeup effect durability is improved, a dizzy makeup phenomenon does not occur, meanwhile, the stability of the BB cream is improved, the irritation is reduced, and bacteria can be effectively killed; and a natural skin-simulated moisturizing film is formed by virtue of a synergistic interaction effect of PCA sodium salt, hyaluronic acid and polyquaternary ammonium salt-51, so that the moisturizing property of the product is improved, and skin is moist and smooth.

Owner:上海禾雅化妆品有限公司

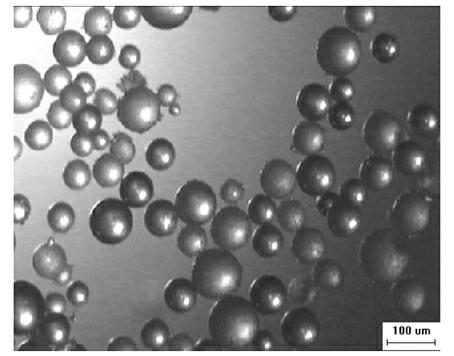

Method for preparing colloidal crystal by emulsion suspension

InactiveCN107604442AHigh interfacial tensionImprove crystal surface uniformityPolycrystalline material growthFrom normal temperature solutionsCoated membraneEmulsion

The invention discloses a method for preparing a colloidal crystal by emulsion suspension. The method comprises the following steps: step 1, preparing a colloidal particle suspension emulsion; step 2,injecting the colloidal particle suspension emulsion into the lower surface of a membrane substrate to be coated, and enabling the suspension emulsion to be suspended at the lower surface of the membrane substrate to be coated under attractive force of the membrane substrate to be coated to the suspension emulsion; and step 3, transferring the to-be-coated membrane substrate suspending the suspension emulsion into an atmosphere with a temperature of 40-150 DEG C, and making the dispersion liquid in the suspension emulsion evaporated to obtain the colloidal crystal. According to the invention,colloidal particles are regularly arranged under actions of force such as capillary force and self gravity generated by evaporation of the dispersion liquid, so that the colloidal crystal is prepared, when the suspension emulsion is suspended downwards, the interfacial tension formed between the liquid surface and the substrate, namely, the capillary force which drives small spheres arranged, canbe increased under actions of the gravity of the dispersion liquid, so that the surface uniformity of the film-forming colloid crystal is improved; and the method has the advantages that the preparation process is simple, the efficiency is high, and complex equipment is not needed.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

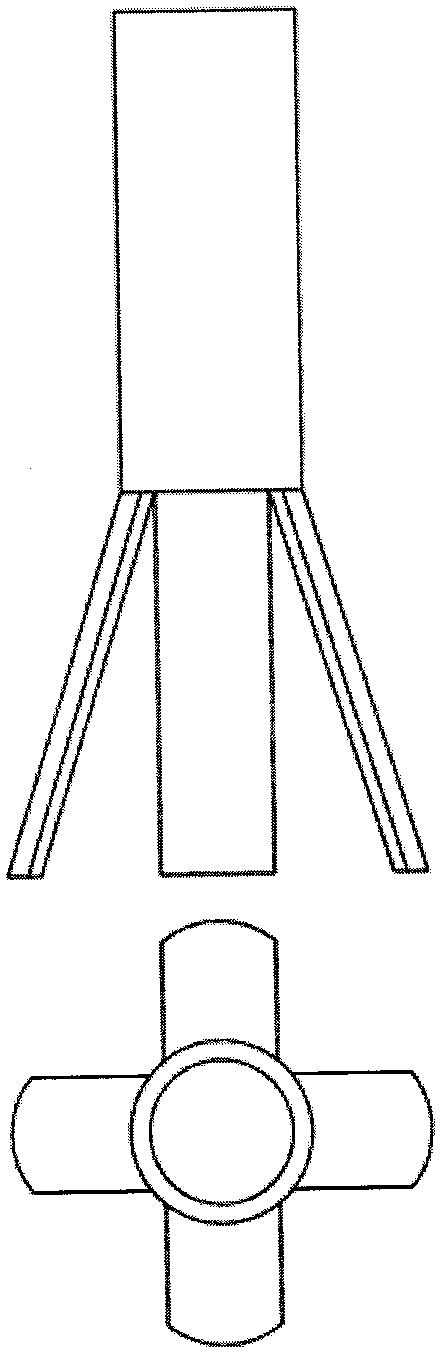

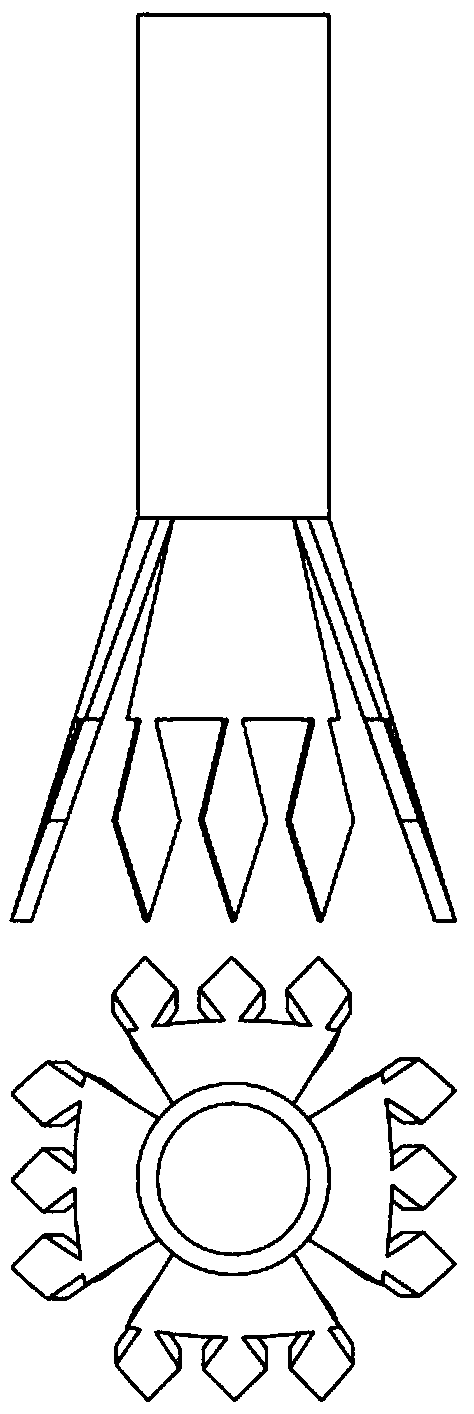

Radial electrospinning nozzle based on rectangular blades

ActiveCN110512292ASolve the blockageHigh interfacial tensionFilament/thread formingHigh concentrationElectrospinning

The invention relates to a radial electrospinning nozzle based on rectangular blades, and belongs to the field of nanofiber preparation. The nozzle comprises a radial spinneret and a cylindrical tube.The radial spinneret is composed of a plurality of uniformly distributed rectangular blades of the same structure, each rectangular blade opens to the outer side to be radial at a certain angle, theradial spinneret is closely and smoothly connected with the cylindrical tube, and barrier-free transport of a spinning fluid can be achieved. The radial electrospinning nozzle based on rectangular blades has the large inner diameter, the needle blocking problem is avoided conveniently, and electrostatic spinning can be conducted on a high-concentration spinning solution system; the radial spinneret with the rectangular blades has the function of stabilizing liquid droplets; meanwhile, the area of the spinning liquid surface is increased, multiple spinning jets can be generated, and the spinning output can be increased conveniently; closed and controllable liquid supply can be achieved by means of an injection pump, and a solvent is not likely to be volatilized; the rectangular blades havethe point effect, and the energy consumption can be lowered; in addition, the radial electrospinning nozzle based on the rectangular blades can be used for alternating current spinning.

Owner:WUHAN TEXTILE UNIV

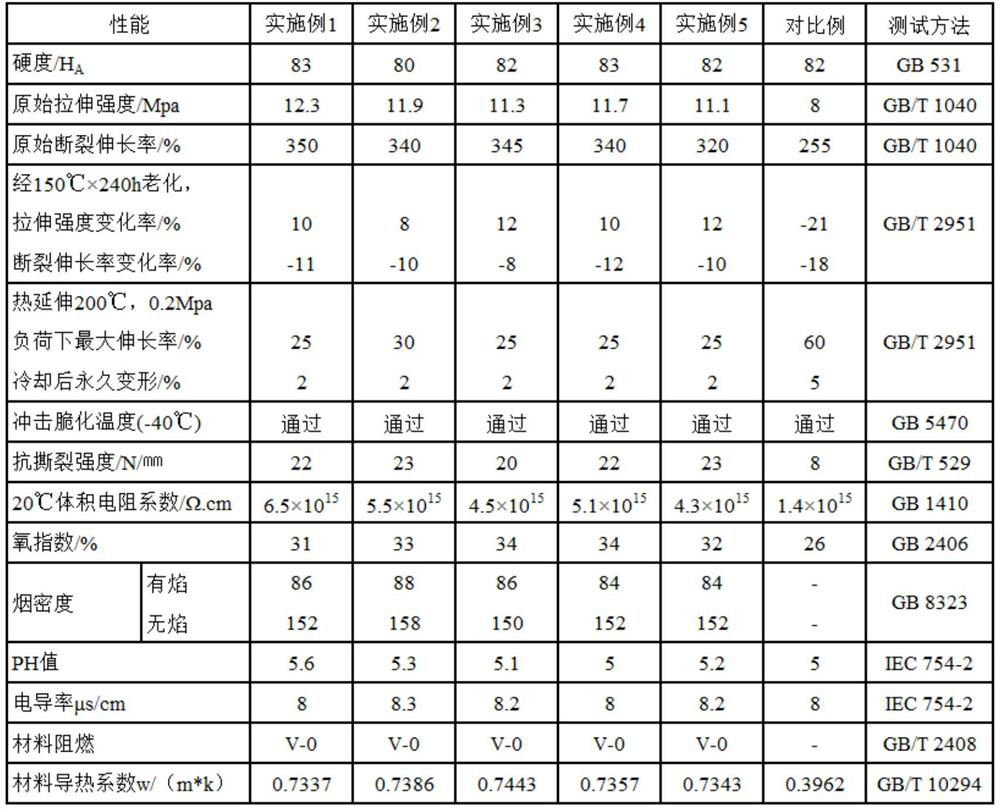

Charging pile cable material and preparation method thereof

The invention relates to a cable, in particular to a charging pile cable material and a preparation method thereof. The flame-retardant EPDM rubber material is prepared from the following materials in parts by weight: 55-70 parts of EPDM rubber, 10-20 parts of ethylene-octene copolymer resin, 8-12 parts of a compatilizer, 6-12 parts of polyethylene-acrylate rubber, 5-10 parts of an ethylene-vinyl acetate copolymer, 2-5 parts of polyphenyl ether, 60-80 parts of a flame retardant, 20-30 parts of a flame-retardant synergist, 15-25 parts of a heat-conducting filler, 0.5-1 part of polyethylene wax, 1.2-2 parts of an antioxidant, 0.9-1.2 parts of a cross-linking agent and 0.1-0.3 part of an anti-degradation agent. The charging pile cable material can simultaneously meet the requirements of softness, high flame retardance, low thermal resistance, high and low temperature resistance, aging resistance, cracking resistance and high insulation.

Owner:WUXI JAKE PLASTIC

Oil pipe paraffin control and scale removal agent and preparation method and application thereof

The invention belongs to the technical field of crude oil paraffin inhibitors, and discloses an oil pipe paraffin inhibitor and a preparation method and application thereof.The preparation method comprises the steps that graphene oxide powder is evenly dispersed in a water solvent under the ultrasonic action to obtain graphene oxide turbid liquid; then, uniformly dispersing a binary polymer monomer and a silane coupling agent into the graphene oxide turbid liquid through primary stirring treatment, and dropwise adding an initiator for suspension polymerization, so that the binary polymer monomer is polymerized on the surface of graphene oxide to obtain a binary polymer-graphene oxide compound; and then adding the descaling agent, stirring for the second time, and uniformly mixing, so as to obtain the paraffin-control descaling agent for the oil pipe. The oil pipe paraffin and scale inhibitor is good in paraffin and scale inhibition effect, the preparation method is simple and easy to operate, the preparation raw materials are low in cost, and the preparation method is green and environmentally friendly.

Owner:天信管业科技集团有限公司

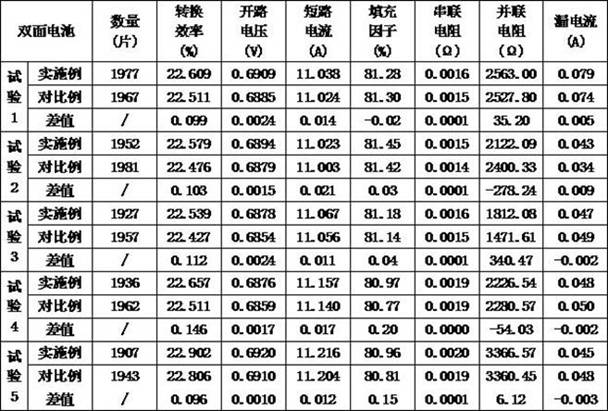

Sulfuric acid etching process method

InactiveCN112349814AEasy to polishImprove reflectivityFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidPhysical chemistry

The invention discloses a sulfuric acid etching process method, which comprises the following steps of: in an etching process of a silicon wafer, setting the initial proportioning amount of pure waterin an etching tank to be 220+ / -50g / L, the initial proportioning amount of hydrofluoric acid to be 100+ / -50g / L, the initial proportioning amount of nitric acid to be 510+ / -50g / L and the initial proportioning amount of sulfuric acid to be 220+ / -50g / L; the pure water supplementing amount of the etching tank is set to be 0 mL / piece, the hydrofluoric acid supplementing amount is set to be 4.0+ / -2.0 mL / piece, the nitric acid supplementing amount is set to be 5.0+ / -2.0 mL / piece, and the sulfuric acid supplementing amount is set to be 1.5+ / -1.0 mL / piece; and according to the method, equipment (suitable for rollers of different types or tooth depths) does not need to be improved, sulfuric acid only needs to be supplemented in the primary preparation and production process of the etching groove, polishing of the back face of the silicon wafer and improvement of the reflectivity can be achieved through comprehensive optimization and adjustment of the process temperature, the circulating flow andthe water film amount, then the purpose of improving the conversion efficiency of the single crystal cell is achieved, and various electrical parameters of the prepared silicon wafer completely meetthe original requirements, and the process is simple and easy to implement.

Owner:平煤隆基新能源科技有限公司

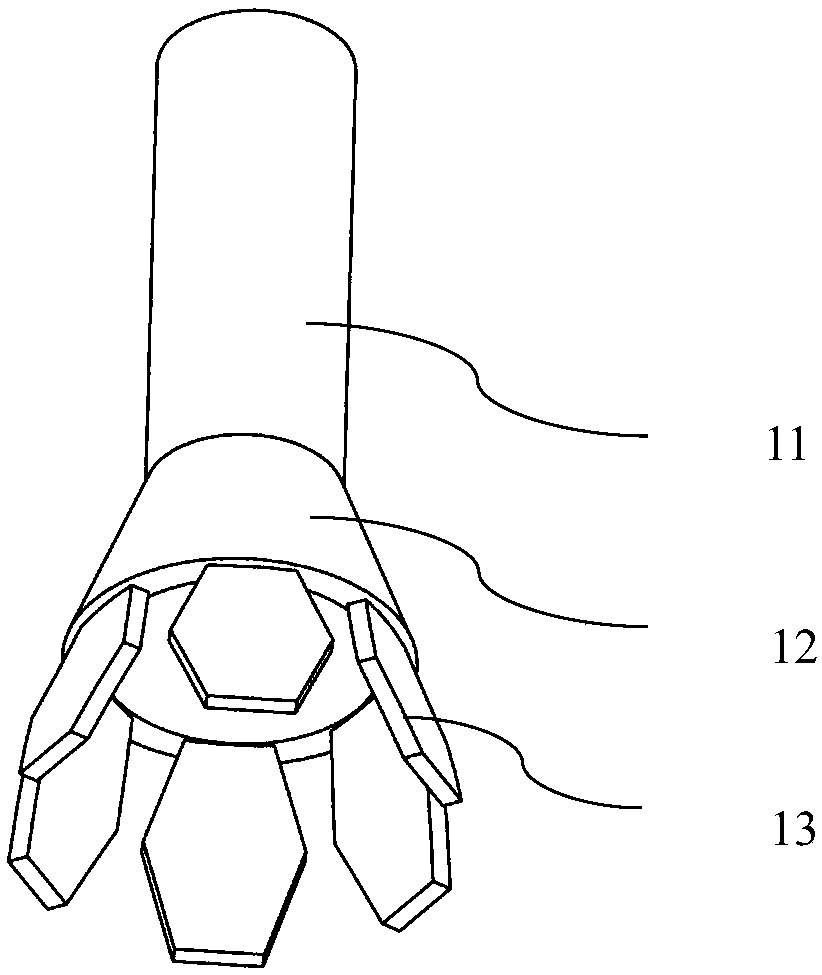

Radial electrospinning nozzle based on differential rhombus blades

InactiveCN109023552AHigh interfacial tensionNot volatileFilament/thread formingHigh concentrationElectrospinning

The invention relates to a radial electrospinning nozzle based on differential rhombus blades, and belongs to the technical field of nanofiber preparation. The radial electrospinning nozzle based on differential rhombus blades is composed of a cylinder tube and a radial spinneret with differential rhombus blades, wherein the radial spinneret is composed of a plurality of radial blades which have the same structure and are uniformly distributed along the circumference; a plurality of differential rhombus blades are arranged at the top of each radial blade at equal interval; the radial spinneretis arranged at the upper part or the lower part of the cylinder tube; and the radial spinneret and the cylinder tube have the same inner diameter at a joint and are closely and smoothly connected, thus being able to realize unobstructed transport of spinning fluids. The radial electrospinning nozzle based on differential rhombus blades has a large inner diameter, thus being beneficial to avoidance of the clogging problem, and can electrospin high concentration spinning solution. Besides, the radial spinneret has the function of stabilizing droplets, and can produce multiple spinning jets, thus being large in the spinning yield. Moreover, the tubular structure of the radial electrospinning nozzle based on differential rhombus blades can achieve closed and controllable liquid supply, and the solvent is not volatile, and the differential rhombus blades have tips to produce higher field strength, thus being able to reduce energy consumption.

Owner:WUHAN TEXTILE UNIV

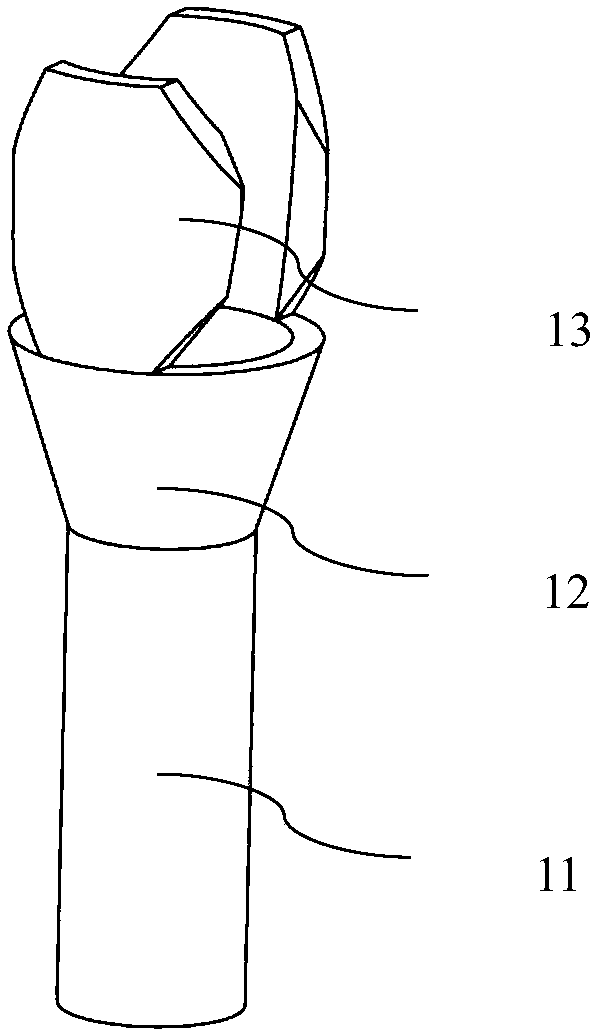

Horn-shaped electrospinning nozzle with differential polygon blades at top

InactiveCN108707980ASolve the blockageHigh interfacial tensionFilament/thread formingHigh concentrationElectrospinning

The invention relates to a horn-shaped electrospinning nozzle with differential polygon blades on the top and belongs to the technical field of nanofiber preparation. The horn-shaped electrospinning nozzle is formed by a cylinder tube, a horn mouth and the differential polygon blades; the differential polygon blades are evenly distributed at the top of the big opening of the horn mouth circumferentially, the horn mouth is located on the upper portion or the lower portion of the cylinder tube, the small opening of the horn mouth is equal to the joint of the cylinder tube in inner diameter withcontact and smooth connection, and barrier-free transportation of spinning fluid can be realized. The horn-shaped electrospinning nozzle with the differential polygon blades at the top is large in theinner diameter, so that plugging of needles can be favorably avoided, and electrospinning can be performed on high-concentration spinning solutions; the differential polygon blades at the top of thespinning nozzle has the function of stabilizing droplets, the area of spinning fluid level is enlarged, multiple spinning jets can be generated, and spinning production is increased; closed and controllable fluid supply can be realized through the tubular structure, and solvents are less prone to volatilization; the differential polygon blades at the top of the horn mouth are provided with tips, so that higher field intensity can be produced, and energy consumption can be reduced.

Owner:WUHAN TEXTILE UNIV

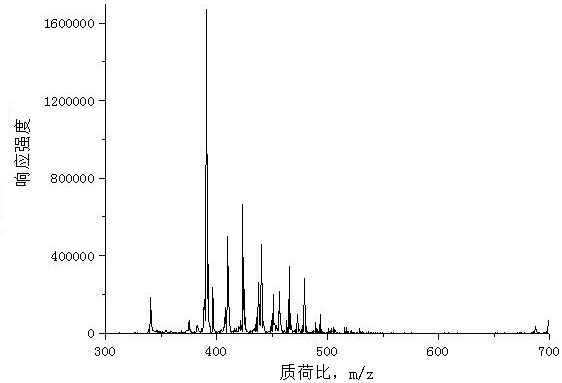

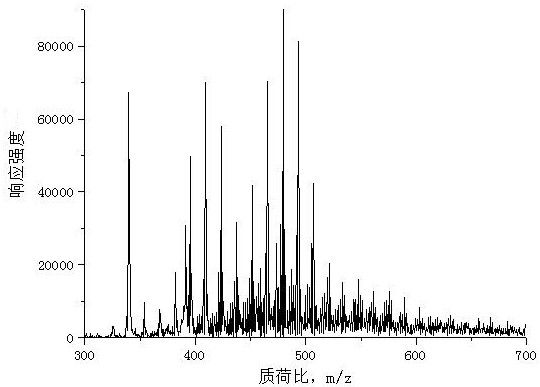

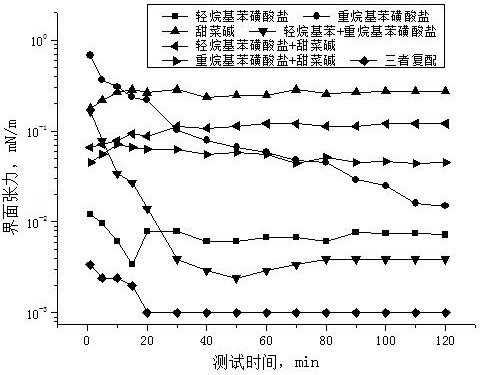

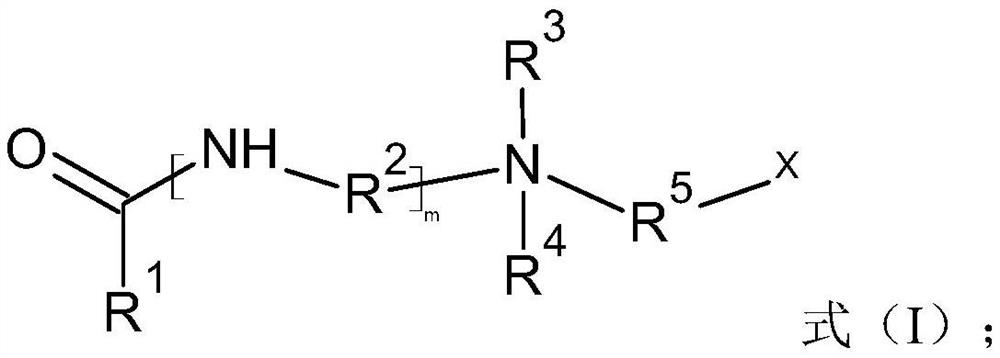

A compound surfactant with ultra-low oil-water interfacial tension and preparation method thereof

ActiveCN112011326BHigh interfacial tensionHigh interface activityDrilling compositionHexadecaneAlkane

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

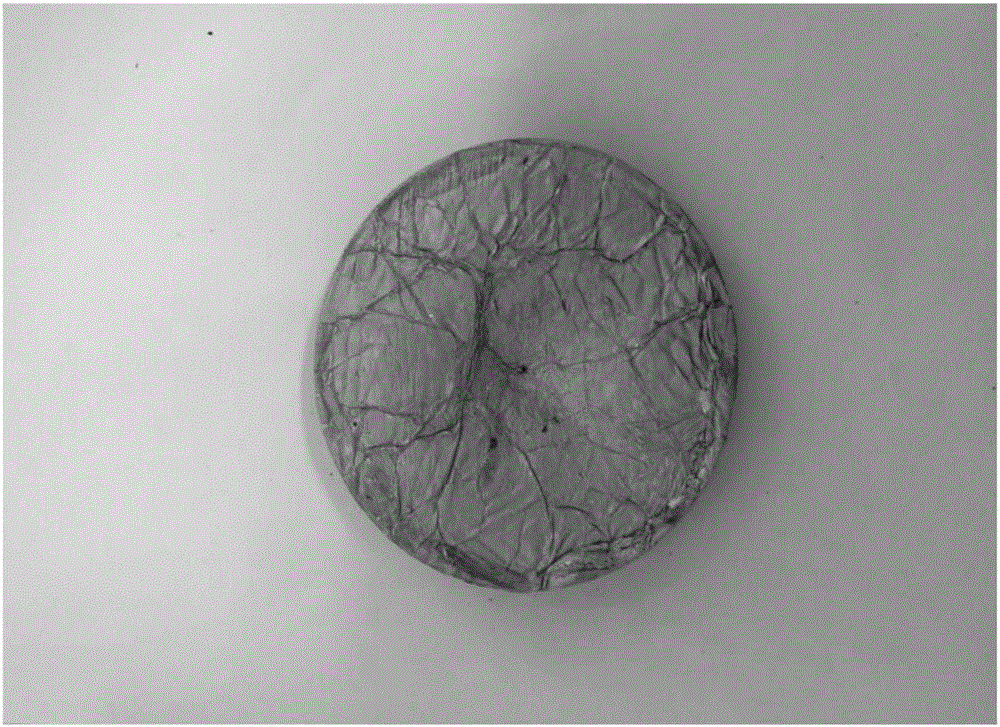

Recycling method of foamed magnesium

The invention provides a recycling method of foamed magnesium. According to the method, the melting temperature of slag is lowered with CaF2 serving as a fluxing agent; then metamorphic blocks formed by mixing and pressing hexachloroethane and aluminum powder are added, and slag conglomeration and metamorphism are performed; and finally, pure molten magnesium is obtained in an argon refining manner, and therefore the foamed magnesium can be recycled. By taking effective measures in the recycling method, the foamed magnesium is successfully recycled, and the recycling rate reaches 80%. While it is guaranteed that the foamed magnesium is successfully recycled, energy consumption in the recycling process is reduced, cost is lowered, the recycling method is safe and environment-friendly and is a recycling method, meeting the production practice requirement, of the foamed magnetism.

Owner:HEBEI UNIV OF TECH

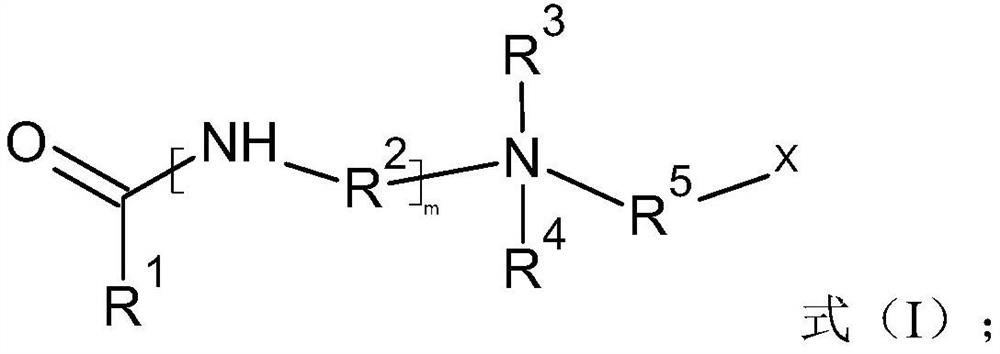

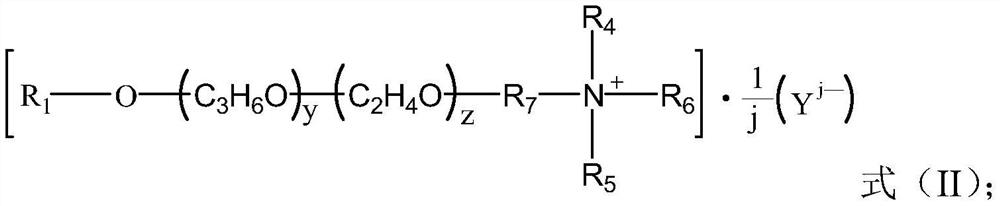

Oil-resistant foam drainage agent composition, foam drainage agent combined liquid and application thereof

ActiveCN113913172AImprove hydrophilicityIncrease liquid carrying capacityDrilling compositionSulfonateBetaine

The invention relates to the field of foam liquid drainage gas production, in particular to an oil-resistant foam liquid drainage agent composition, a foam liquid drainage agent combined liquid and application thereof. The foam drainage agent composition contains alkyl amido betaine with a structure as shown in a formula (I), polyether quaternary ammonium salt with a structure as shown in a formula (II) and a sulfonate anionic surfactant, and has excellent foam oil resistance, thermal stability, foamability and liquid carrying property, so that the foam drainage agent composition has excellent foam drainage performance when in use. Meanwhile, the foam drainage agent combined liquid is applied to the liquid drainage and gas production process of a gas well, has excellent oil resistance, thermal stability, foamability and liquid carrying property, and can ensure smooth gas production of the gas well.

Owner:CHINA PETROLEUM & CHEM CORP +1

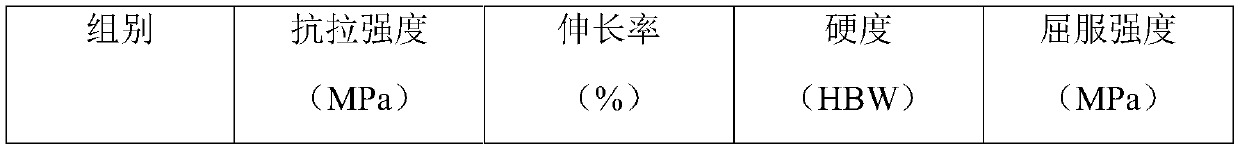

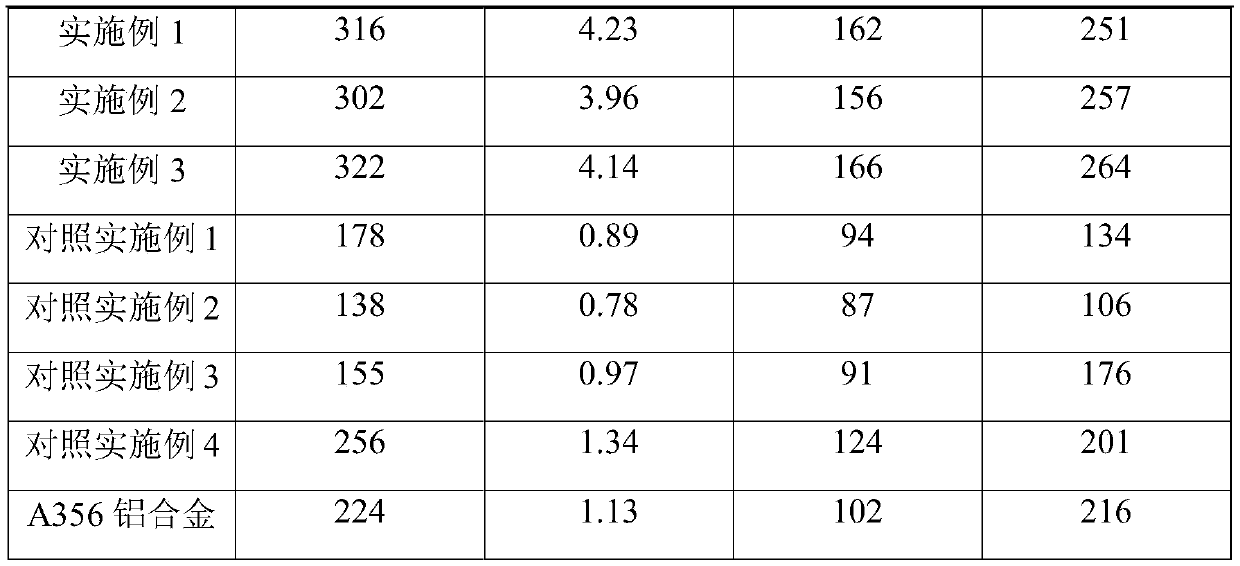

Covering comprehensive material as well as preparation method and application thereof

InactiveCN109988930AImprove refinement metamorphic effectImprove the efficiency of spoilage treatmentMANGANESE ACETATESlag

The invention discloses a covering comprehensive material as well as a preparation method and application thereof, and relates to the field of aluminum alloy modifiers. The covering comprehensive material is prepared from the following raw materials of, in percentage by weight, 3%-9% of aluminum chloride, 0.5%-0.8% of manganese acetate, 2%-9% of sodium nitrate, 0.11%-0.18% of zinc fluoride, 8%-12%of potassium chloride, 12%-16% of sodium chloride, 6%-10% of sodium fluoride, 9%-18% of composite powder and the balance sodium fluoroaluminate; when the covering comprehensive material is used as the modifier, the modification refinement elements are matched with each other, so that the modification effect is excellent; when the modifier is used as a covering agent, so that the melt can be prevented from being absorbed and oxidized, the heat preservation effect is good, the exhaust emission is promoted, the potash feldspar clay powder in the raw materials can be used as a modifier carrier toremove gas and remove slag, the smelting step is simplified, the smelting efficiency is improved, and the alloy hardness can be remarkably improved by the rich aluminum oxide and silicon oxide. Whenthe aluminum alloy is smelted, the strength, the plasticity and the hardness of an aluminum alloy casting can be remarkably improved by using the covering comprehensive material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

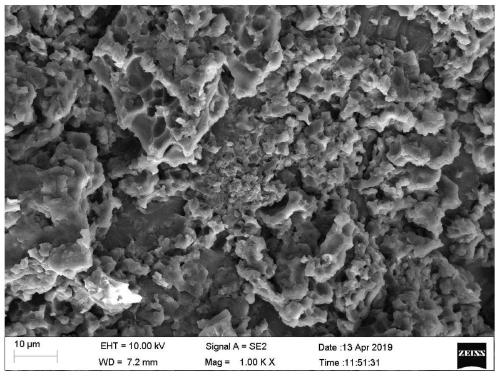

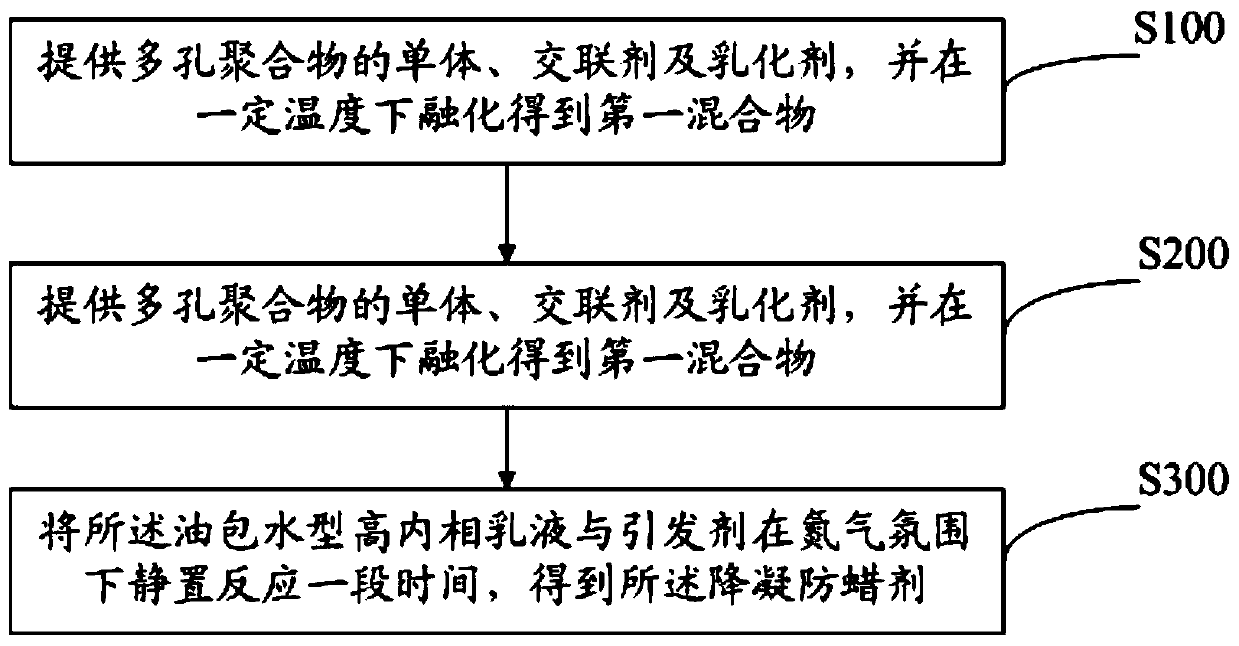

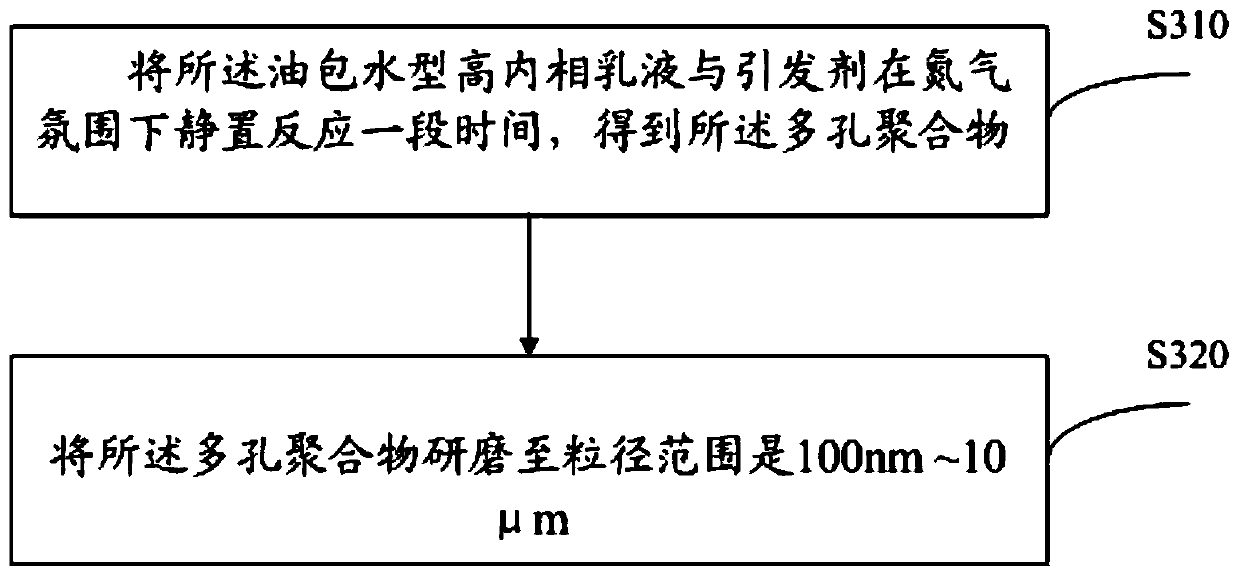

Pour point reducing paraffin inhibitor, and preparation method thereof

The invention discloses a pour point reducing paraffin inhibitor. The pour point reducing paraffin inhibitor comprises a porous polymer which is capable of realizing eutectic reaction and / or adsorption reaction with wax in crude oil, wherein the surface and the internal part of the porous polymer comprise alkyl side chains; and the alkyl side chains are capable of realizing eutectic reaction and / or adsorption reaction with wax in crude oil. The above method is capable of improving wax containing crude oil low temperature rheological property and reducing deposition of wax on tube walls.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com