Charging pile cable material and preparation method thereof

A cable material and charging pile technology, applied in the field of cables, can solve the problems of poor heat and aging resistance and scratch resistance, heat can not be dissipated in time, and limit the current carrying capacity of the cable, and achieve ozone resistance, aging resistance, halogen-free resistance and other problems. The effect of improving the combustion requirements and reducing the interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

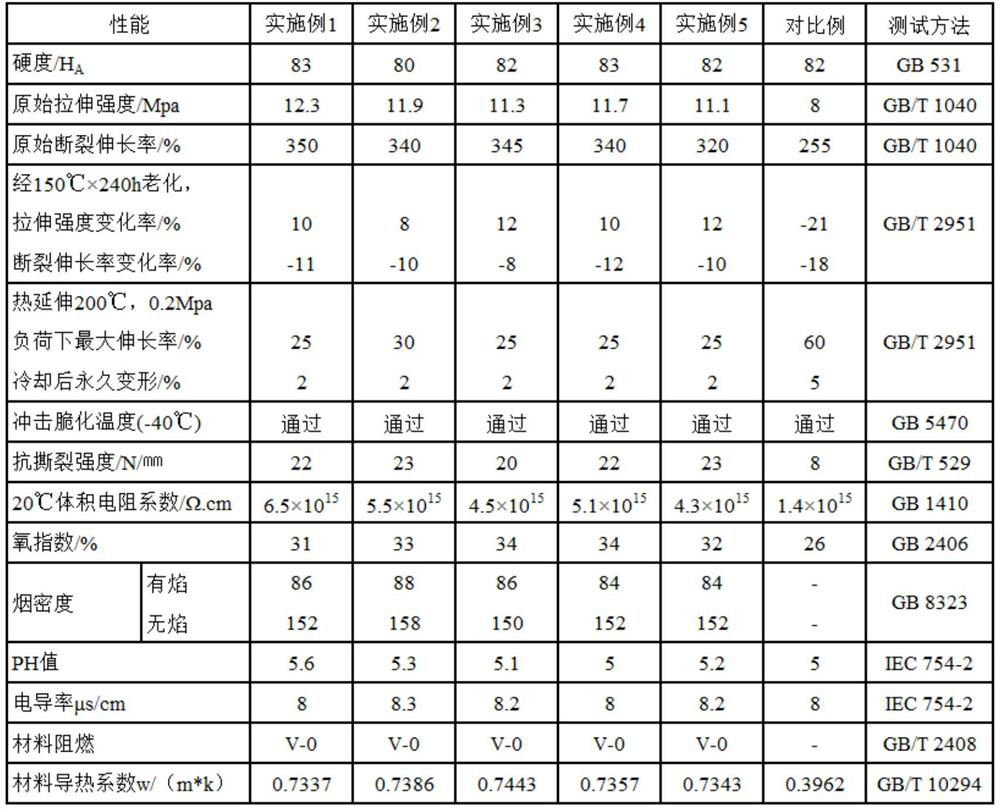

Examples

preparation example Construction

[0032] The preparation method of charging pile cable material comprises the following steps:

[0033] S1. Preparation of thermally conductive filler: After mixing silicon nitride and aluminum nitride uniformly in a weight ratio of 3:1, add a 2% mass fraction of silane coupling agent in anhydrous ethanol solution, and ultrasonically disperse at 60-70°C 2h, filter and remove the filtrate and then dry;

[0034] S2. Preparation of cable materials: heat-conducting filler and EPDM rubber, ethylene octene copolymer resin, maleic anhydride graft modified resin, polyethylene-acrylate rubber, ethylene-vinyl acetate copolymer prepared in step S1 Compounds, polyphenylene ether, flame retardant, flame retardant synergist, polyethylene wax, antioxidant, crosslinking agent, anti-degradation agent are added to the heating internal mixer and mixed to 170-175°C, and the mixing time is 15-20 Minutes, made into lump materials;

[0035] S3. Granulation: put the lump material prepared in step S2 ...

Embodiment 1

[0037] The charging pile cable material is made of the following materials in parts by weight:

[0038] 55 parts of EPDM rubber, 20 parts of ethylene octene copolymer resin, 8 parts of compatibilizer, 12 parts of polyethylene-acrylate rubber, 5 parts of ethylene-vinyl acetate copolymer, 3 parts of polyphenylene ether, flame retardant 60 parts, 20 parts of flame retardant synergist, 15 parts of thermally conductive filler, 0.6 part of polyethylene wax, 1.2 parts of antioxidant, 0.9 part of crosslinking agent, 0.2 part of anti-degradation agent.

Embodiment 2

[0040] The charging pile cable material is made of the following materials in parts by weight:

[0041] 60 parts of EPDM rubber, 10 parts of ethylene octene copolymer resin, 10 parts of compatibilizer, 12 parts of polyethylene-acrylate rubber, 8 parts of ethylene-vinyl acetate copolymer, 2 parts of polyphenylene ether, flame retardant 70 parts, 25 parts of flame retardant synergist, 20 parts of thermally conductive filler, 0.8 part of polyethylene wax, 1.6 parts of antioxidant, 1.2 parts of crosslinking agent, 0.3 part of anti-degradation agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com