Viscose cotton yarn gluing process

A cotton yarn and gluing technology, which is used in textile processing machine accessories, liquid/gas/vapor yarn/filament processing, textiles and papermaking, etc. Improve the effect of gluing, gluing evenly, and enhance the effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

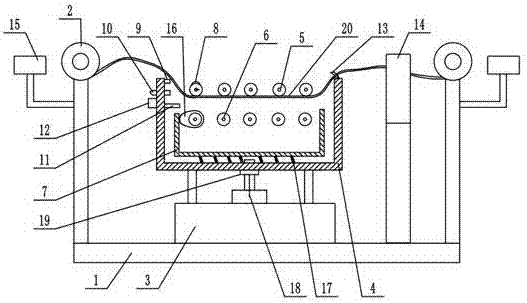

[0030] An example basically looks like this:

[0031] The viscose cotton yarn gluing process comprises the following steps:

[0032] S1: cleaning: cleaning the cotton yarn 20 to be glued to remove impurities in the cotton yarn 20; cleaning the cotton yarn 20 with tap water at 20°C-35°C.

[0033] S2: drying before gluing: drying the washed cotton yarn 20 at a drying temperature of 30°C-40°C.

[0034] S3: Cotton yarn combing: unwinding the dried cotton yarn 20 and collecting it into rolls.

[0035] S4: Stirring and gluing: Wrap the cotton yarn 20 on various parts of the gluing device in turn, and apply glue to the cotton yarn 20. During the gluing process, the glue is constantly stirred to prevent the glue from solidifying or delaminating. The temperature of the gluing glue is 20°C -35°C.

[0036] S5: squeegee: a squeegee is installed on the gluing device to squeegee the cotton yarn 20 after gluing, and the squeegee is a rubber squeegee.

[0037] S6: drying after gluing: dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com