Manufacturing method of static down flake and mixed down

A manufacturing method and flake technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of composite down flock structure, inconvenient manufacturing method, too large difference between vertical and horizontal tension ratio, large energy consumption, etc., and achieve significant economical benefits. Benefits and social benefits, the effect of reducing socially necessary labor time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-31

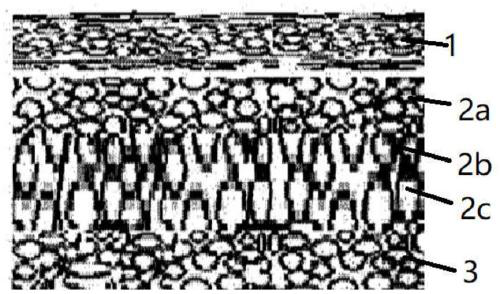

[0066] Select different raw materials and raw material weight ratios for the upper, middle and lower layers of flakes to make multi-layer composite static down flakes according to the following steps. A total of 31 specific examples are cited. The ingredients of each specific embodiment are shown in Table 1 below.

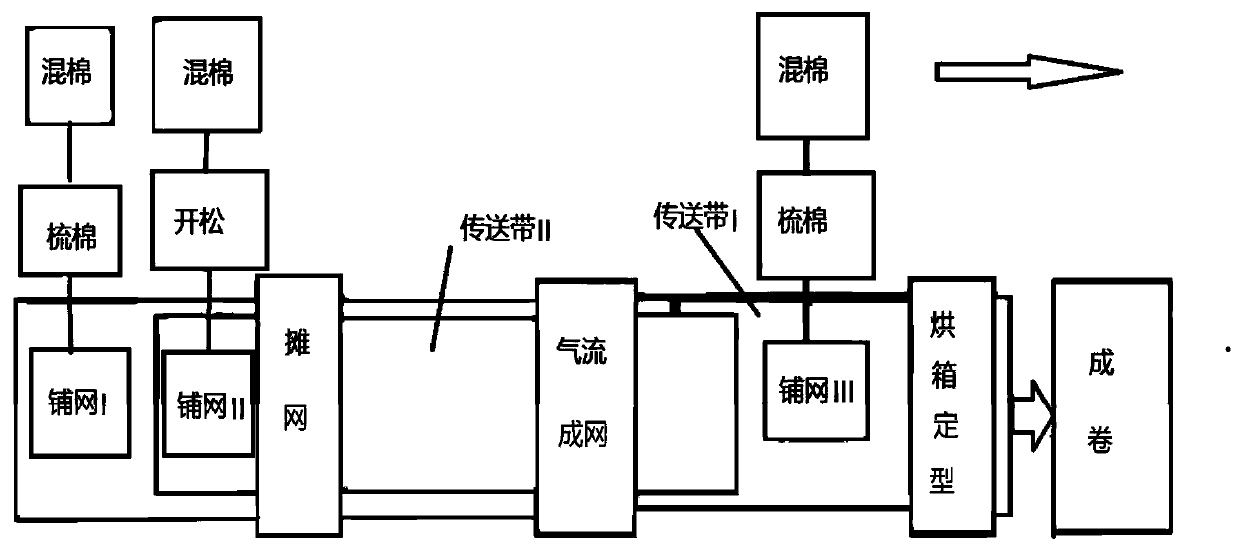

[0067] Such as figure 1 As shown, the flow chart of the manufacturing method of the multi-layer composite static down batting of the present invention is shown.

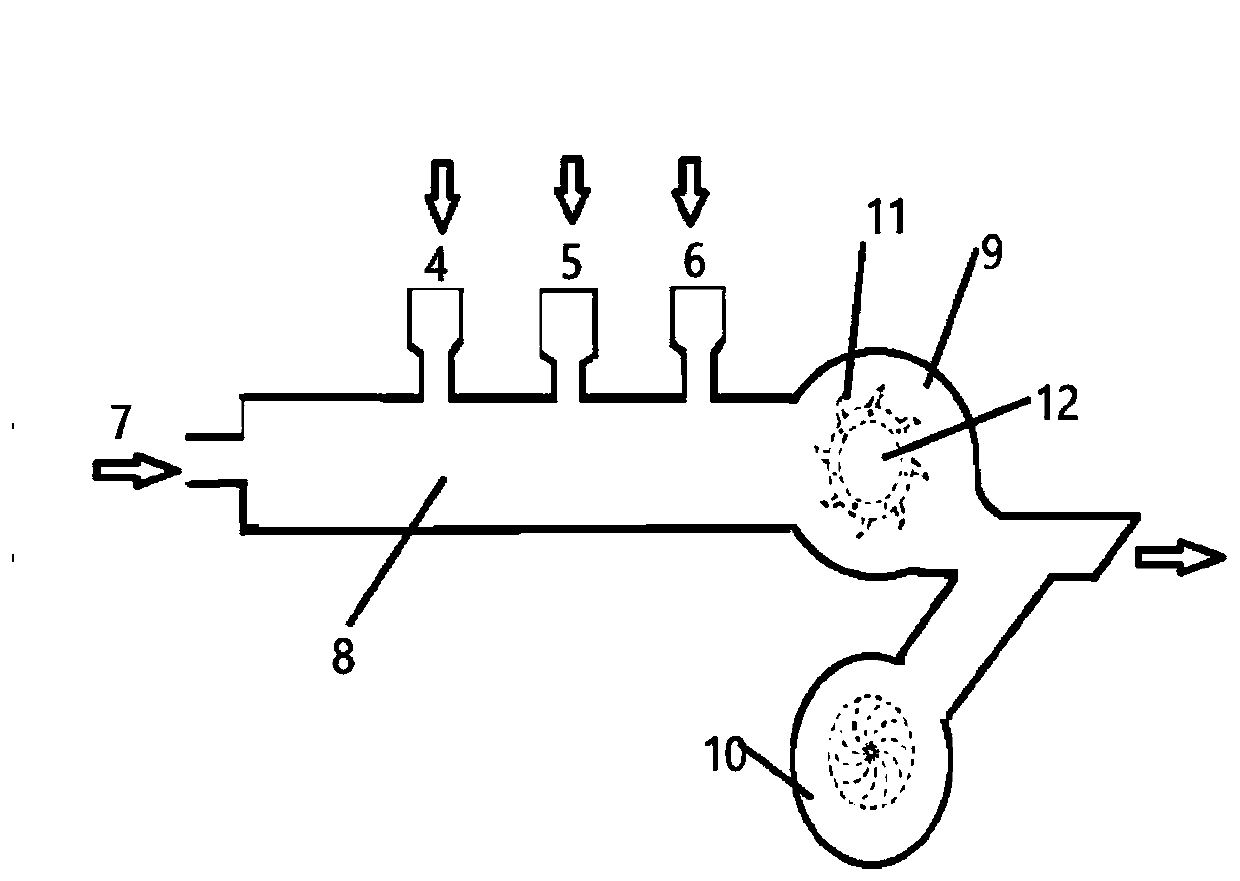

[0068] Firstly, the animal and plant fibers and low melting point fibers are blended, carded, and laid at the laying point I to make a continuous lower layer of wadding, which is sent to the laying point III under the conveyance of the conveyor belt I, where the animals and plants are laid. Fibers and low-melting fibers are mixed, opened, and laid at Laying II, then the down fibers mixed with functional materials are paved, and the middle layer flakes are made by air-laid, which are also conveyed by the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com