Sulfuric acid etching process method

A process method, sulfuric acid technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effect of increasing corrosion uniformity, increasing the concentration of chemical solution, and increasing the concentration of hydrogen ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

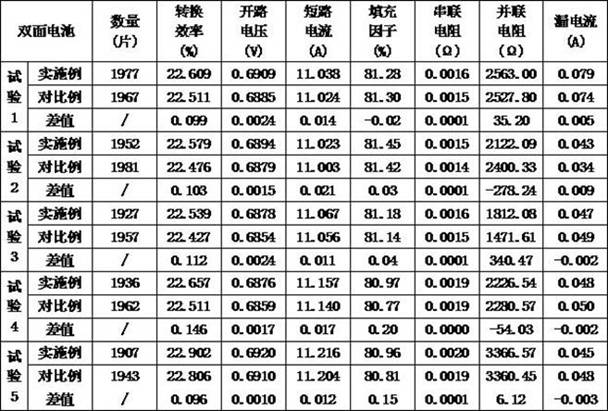

[0043]Example: Using the process of the invention

[0044]After using 166mm×166mm P-type monocrystalline silicon wafers with a resistivity of 0.4~1.1Ω•cm for texturing, diffusion and SE doping, the wafers are automatically fed to the etching and feeding area. The wafer spacing and speed The etched groove roller and structure, and other groove structures and processes are unchanged.

[0045]The temperature of the etching tank of the etching machine is set to 12℃, the circulating flow rate is set to 40 L / min, the amount of water film is set to 20ml, the initial dosage: the initial dosage of pure water is set to 225g / L, the initial dosage of hydrofluoric acid Set 92.5g / L, the initial dosage of nitric acid to 483.5g / L, and the initial dosage of sulfuric acid to 226g / L; replenishment volume: water replenishment volume is set to 0mL / tablet, hydrofluoric acid replenishment volume is set to 3.78mL / tablet, nitric acid The amount of fluid replacement was set to 4.11 mL / tablet, and the amount of sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com