Radial electrospinning nozzle based on rectangular blades

A radial and vane technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of high energy consumption, difficult control of fiber quality, needle blockage and other problems of needle-free electrospinning technology, and achieve increased Spinning liquid surface area, stable droplets, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

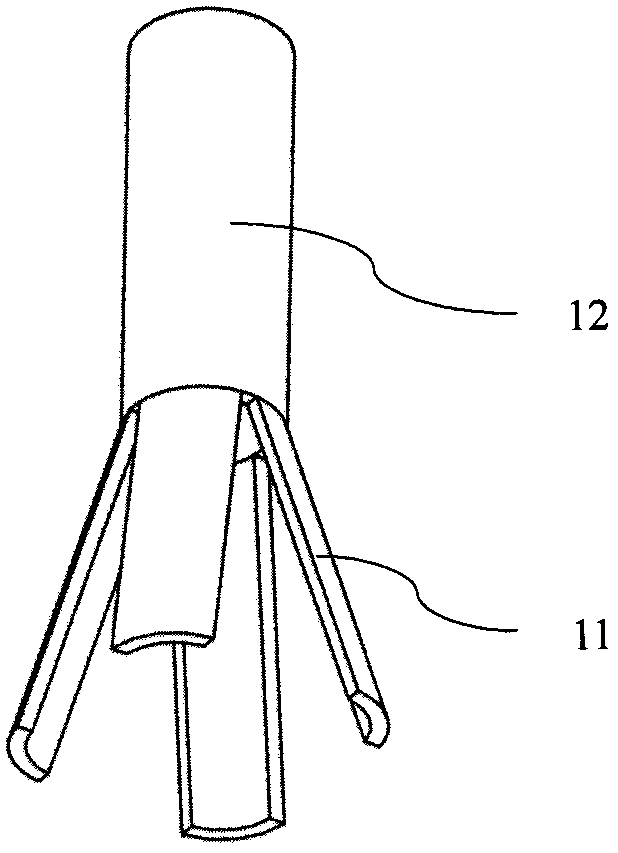

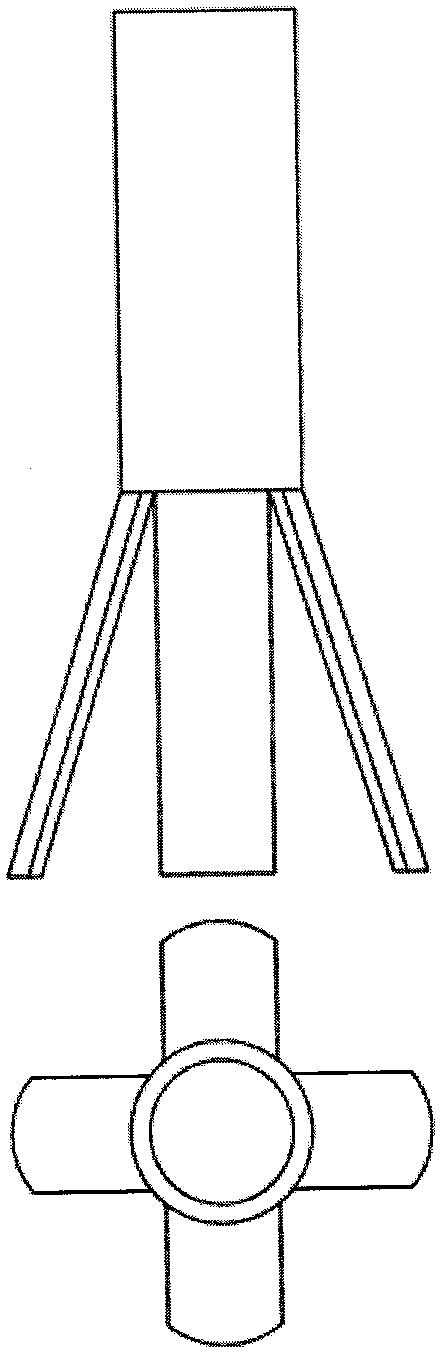

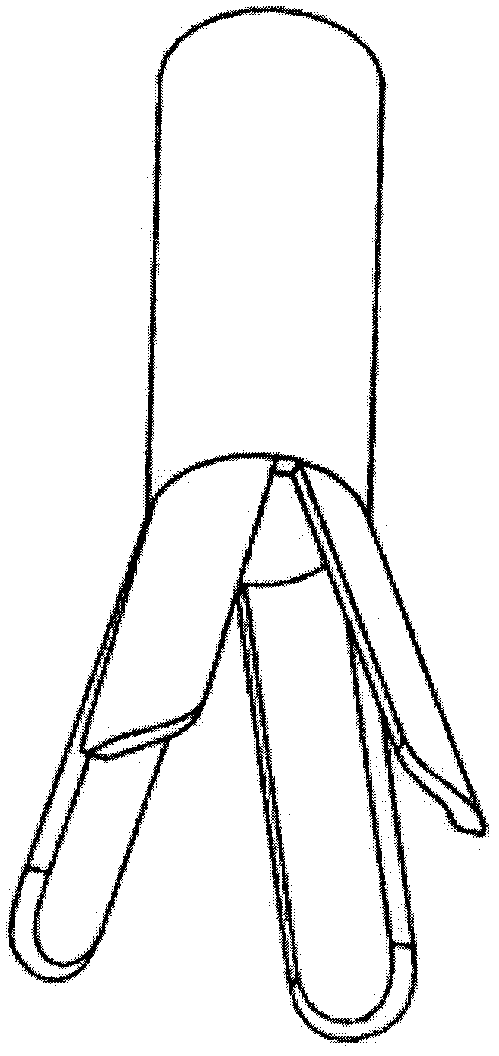

[0012] The present invention provides a radial electrospinning nozzle based on rectangular blades (see Figure 1~4 ), including a radial spinneret 11 and a cylindrical tube 12. figure 1 and figure 2 As shown, it is an embodiment of the present invention—a radial electrospinning nozzle with 4 rectangular blades, the radial spinneret is located at the lower part of the cylindrical tube, and the inner diameter of the radial spinneret is exactly the same as the inner diameter of the cylindrical tube. Consistent and tightly connected, it can realize the unobstructed transportation of spinning fluid; the radial spinneret is composed of 4 rectangular blades uniformly distributed on the circumference, each rectangular blade is opened 30° outward, and the thickness of the rectangular blade is 0.2mm, the rectangular blade is planar along the length direction, the len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com