An aqueous ceramic/PVDF mixed coating slurry, a preparation method and an application thereof

A ceramic material and water-based technology, which is applied in the field of water-based ceramic/PVDF mixed coating slurry and its preparation, can solve the problem of uneven dispersion of coating particles of mixed-coated separators, shortened cycle life of lithium ion batteries, and uneven local current density. and other problems, to achieve the effect of strong binding force, dense surface and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

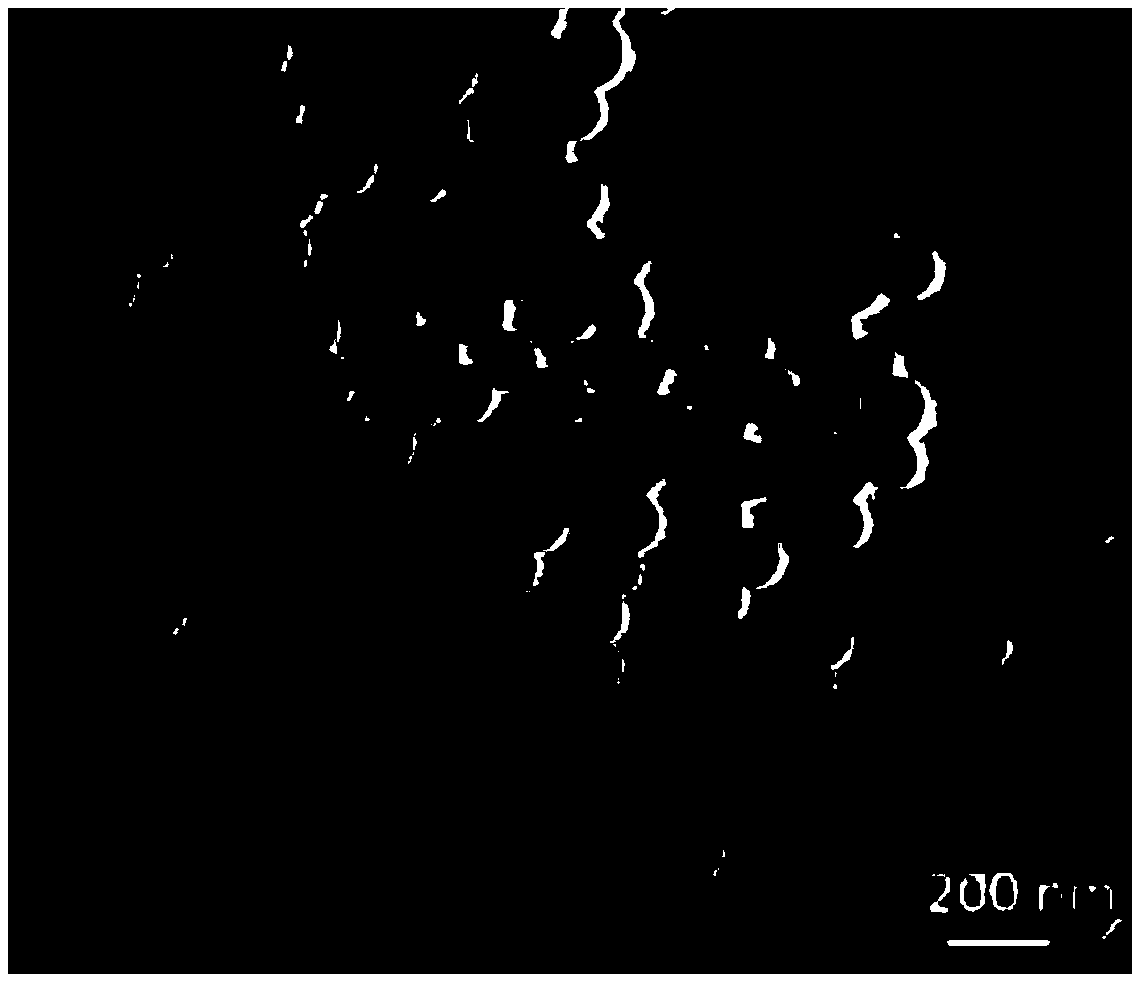

Image

Examples

Embodiment 1

[0051] Add 170g of high-purity water, 0.5g of perfluoroalkyl acrylate, 0.5g of perfluoroalkyl carboxylic acid amine, 0.5g of tert-butyl hydroperoxide and 1g of acetone into an autoclave filled with nitrogen. Under the conditions, 60g of vinylidene fluoride monomer and 40g of hexafluoropropylene monomer gas are continuously introduced into the mixed solution, and the reaction pressure is controlled to 4.0Mpa by adjusting the gas flow rate. After reacting for 8 hours, filter and wash 5 times with pure water to obtain Concentrated PVDF polymer emulsion, adding deionized water to the concentrated PVDF polymer emulsion to adjust the solid content, and preparing a water-based PVDF polymer emulsion with a mass fraction of 20%.

[0052] Add 20g magnesium hydroxide, 0.1g styrene-maleic anhydride and 0.4g sodium polyacrylate in 45g deionized water, after stirring for 3 hours, add 0.2g hydroxyethyl cellulose and 15g polyurethane, continue stirring for 6 hours, and finally 20g of water-ba...

Embodiment 2

[0056] Add 150g of high-purity water, 0.5g of sodium perfluoroalkane sulfonate, 0.9g of tert-butyl hydroperoxide and 0.8g of acetone into an autoclave filled with nitrogen, mix well, and continue to pass through the mixed solution at 80°C Add 60g vinylidene fluoride monomer and 40g hexafluoropropylene monomer gas, control the reaction pressure to 2.0Mpa by adjusting the gas flow rate, after reacting for 10h, filter the prepared PVDF emulsion, wash 3 times with pure water to obtain concentrated PVDF For the polymer emulsion, deionized water is added to the concentrated PVDF polymer emulsion to adjust the solid content, and the water-based PVDF polymer emulsion with a mass fraction of 20% is prepared.

[0057] Add 10g of aluminum oxide and 0.01g of sodium polyacrylate to 45g of deionized water, and after stirring for 8 hours, add 0.25g of sodium carboxymethyl cellulose, 0.25g of sodium alginate and 7.5g of styrene-butadiene latex, continue stirring for 10 hours, and finally mix 4...

Embodiment 3

[0061] Add 200g of high-purity water, 0.8g of perfluoroalkyl acrylate, 0.3g of tert-butyl hydroperoxide and 1.7g of acetone into an autoclave filled with nitrogen. 60g vinylidene fluoride monomer and 40g hexafluoropropylene monomer gas, control the reaction pressure to 1.5Mpa by adjusting the gas flow rate, after 15 hours of reaction, filter the prepared PVDF emulsion, wash 4 times with pure water to obtain concentrated PVDF polymerization Add deionized water to the concentrated PVDF polymer emulsion to adjust the solid content, and prepare a water-based PVDF polymer emulsion with a mass fraction of 20%.

[0062] Add 10g titanium dioxide, 20g boehmite and 2.0g polyethylene glycol in 45g deionized water, after stirring for 3 hours, add 0.5g methyl hydroxyethyl cellulose, 5.0g styrene-acrylic latex and 6.0g polyacrylate emulsion, continue Stir for 6 hours, and finally add 10 g of water-based PVDF polymer emulsion and 0.05 g of fluoroalkyl ethoxy ether alcohol simultaneously and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com