Horn-shaped electrospinning nozzle with differential polygon blades at top

A polygonal and trumpet-shaped technology, which is applied in textiles and papermaking, fiber processing, filament/thread forming, etc., can solve the problems of high energy consumption, difficult control of fiber quality, and inconvenient cleaning of needle-free electrospinning technology, achieving increased Large spinning output, stable droplet, avoiding the effect of needle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

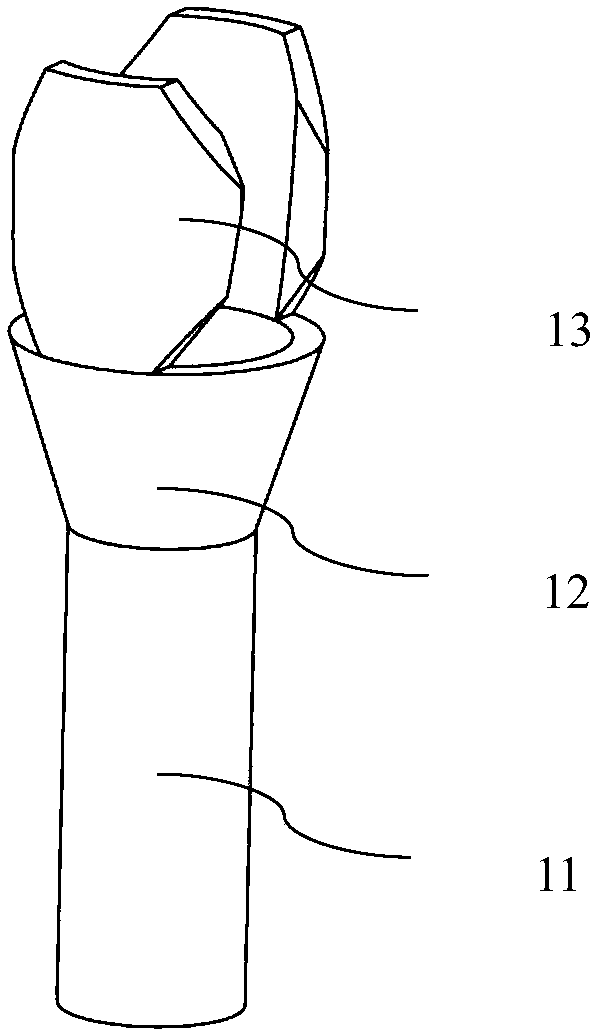

[0012] Embodiment one: figure 1 As shown, it is an embodiment of the radial electrospinning nozzle based on differential polygonal blades of the present invention—an electrospinning nozzle with two differential polygonal blades, the outward opening angle of the differential polygonal blades is 0°, and the cone angle of the bell mouth is 30°. The spinning nozzle is specifically: the number of the differential polygonal blades 13 is 2, uniformly distributed on the top of the large mouth of the bell mouth 12 along the circumference, and the bell mouth 12 is located at the top of the cylindrical tube 11 (spinning upwards), The inner diameter of the bell mouth 12 is equal to the junction of the cylindrical tube 11, and the connection is tight and smooth, which can realize the barrier-free transportation of spinning fluid; the inner diameter of the cylindrical tube 11 is 1.6mm, the length is 5mm, and the wall thickness is 0.2mm; the height of the bell mouth 12 is 2mm, the cone angle...

Embodiment 2

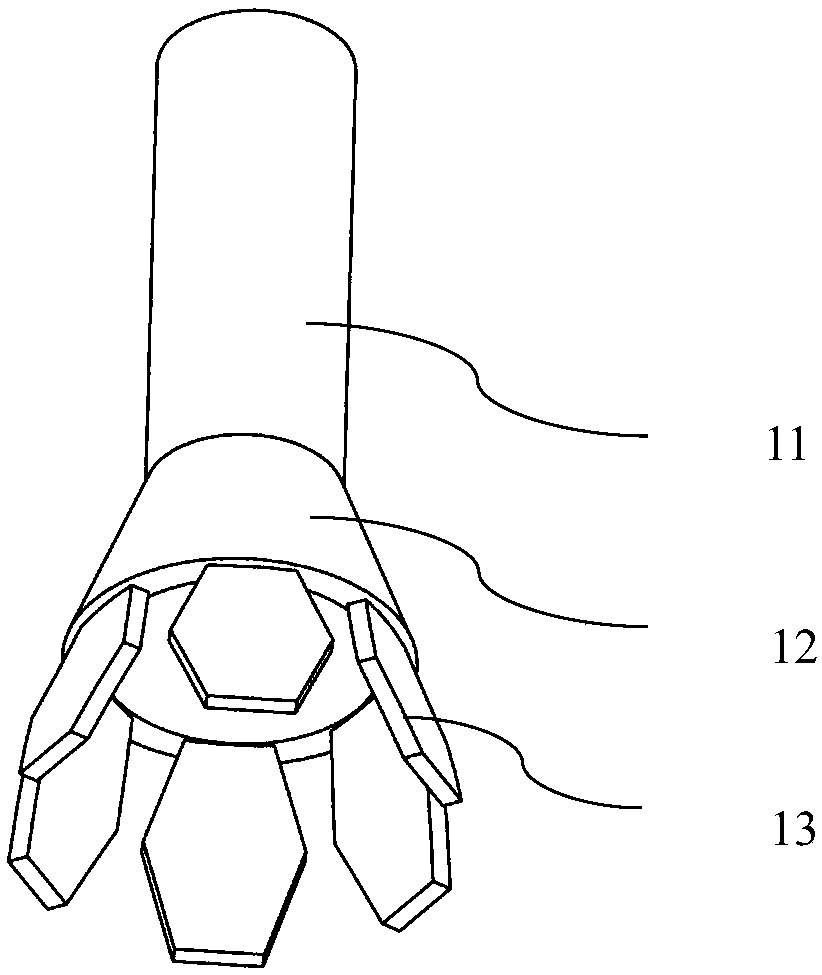

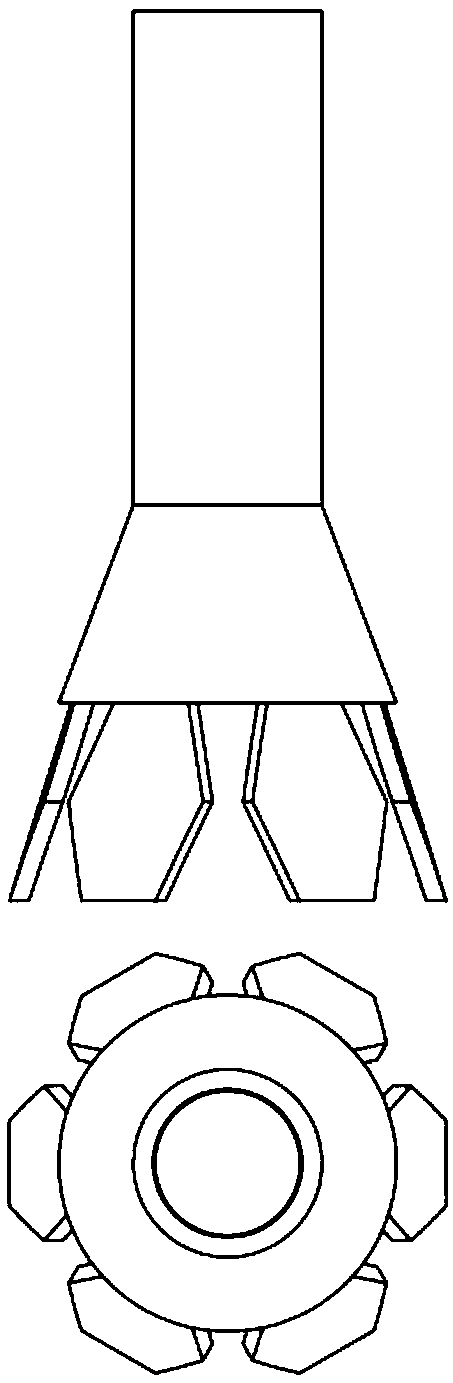

[0013] Embodiment two: figure 2 and image 3 As shown, it is an embodiment of the radial electrospinning nozzle based on differential polygonal blades of the present invention—an electrospinning nozzle with 6 differential polygonal blades, the outward opening angle of the differential polygonal blades is 45°, and the cone angle of the bell mouth is 45°. The spinning nozzle is specifically: the bell mouth 12 is located at the bottom of the cylindrical tube 11 (spinning downwards), the inner diameter of the junction of the bell mouth 12 and the cylindrical tube 11 is equal, and the connection is tight and smooth, which can Realize the unobstructed transportation of spinning fluid; the differential polygon blades 13 are evenly distributed on the top of the bell mouth 12 along the circumference; the inner diameter of the cylindrical tube 11 is 1.6mm, the length is 5mm, and the wall thickness is 0.2mm; the horn The mouth 12 has a height of 2mm, a cone angle of 45°, and a wall thi...

Embodiment 3

[0014] Embodiment three: Figure 4As shown, it is an embodiment of the trumpet-shaped electrospinning nozzle with differential polygonal blades on the top of the present invention used for large-scale nanofiber production——7 trumpet-shaped electrospinning nozzles with differential polygonal blades on the top are arranged in a linear array An electrospinning head, which contains 7 trumpet-shaped electrospinning nozzles with differential polygonal blades at the top, and the distance between the trumpet-shaped electrospinning nozzles is 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com