Pour point reducing paraffin inhibitor, and preparation method thereof

A wax inhibitor and porous polymer technology, which is applied in the field of pour point depressant wax inhibitor and its preparation, can solve the problem that the low temperature rheological properties of waxy crude oil cannot be effectively improved, and achieve the improvement of nucleation barrier, reduction of deposition, The effect of lowering the freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

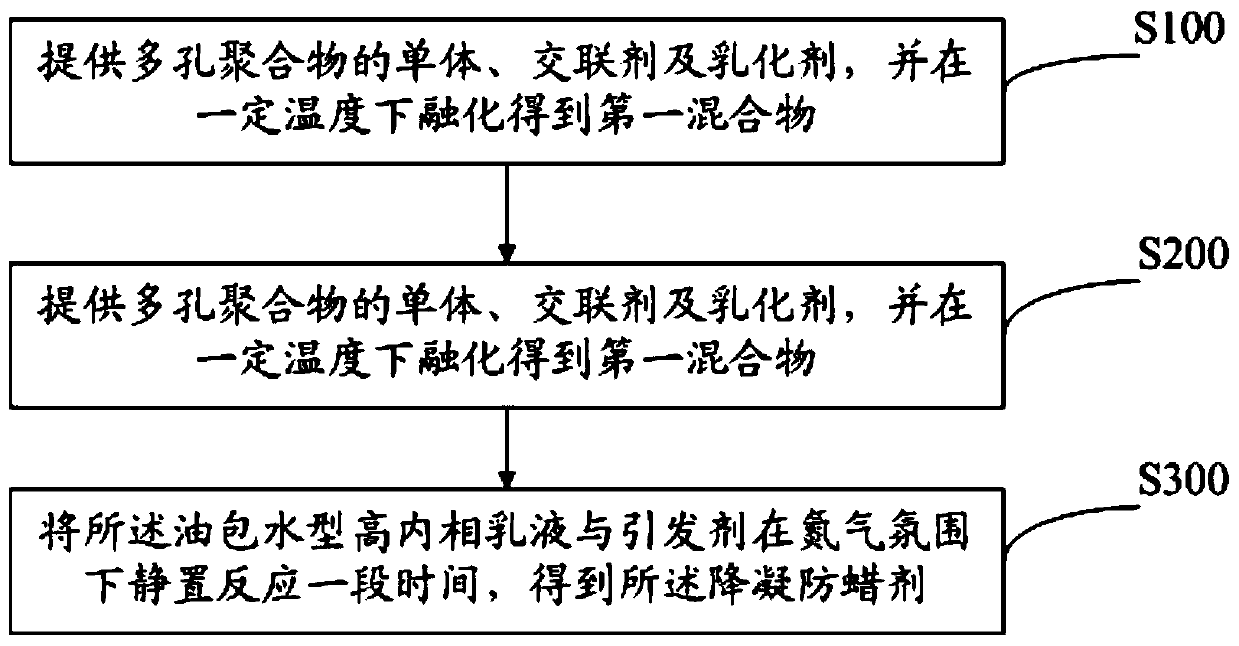

[0056] 26mL of octadecyl acrylate (reactive monomer), divinylbenzene (crosslinking agent) of 10% of the mass of octadecyl acrylate, Span-80 (emulsifier) of 30% of the mass of octadecyl acrylate ) heating and melting at 70°C to obtain the first mixture;

[0057] The first mixture was emulsified with 74 mL of distilled water for 30 min under stirring to prepare a water-in-oil type high internal phase emulsion;

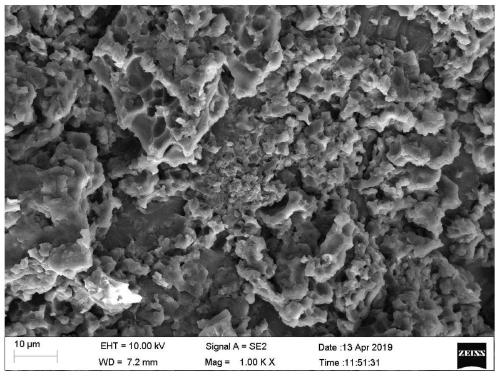

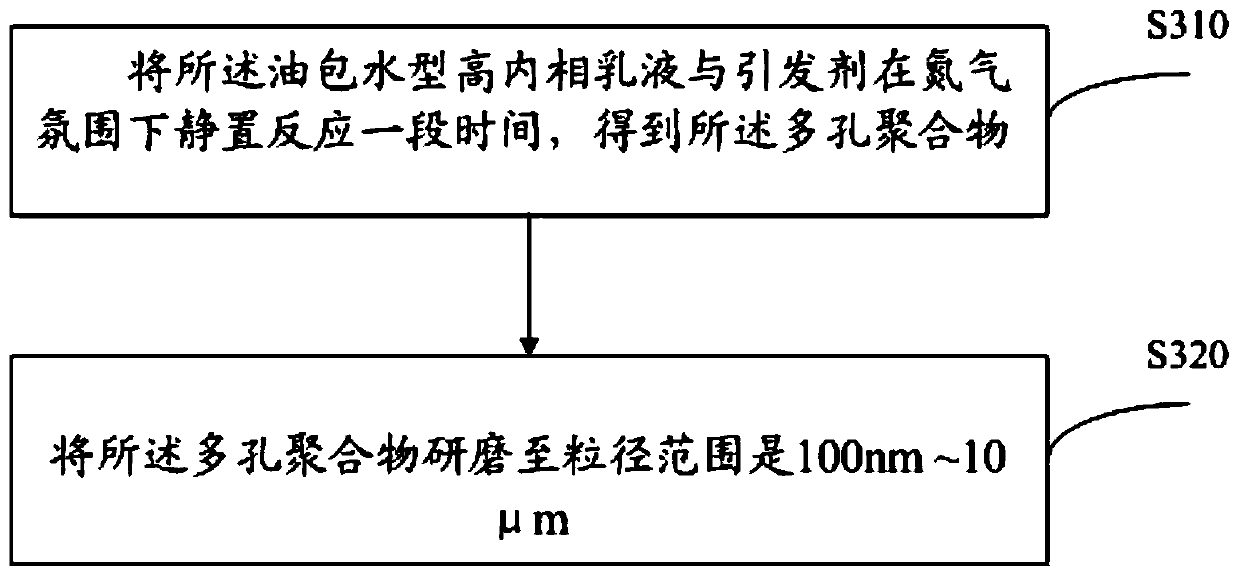

[0058] Using azobisisobutyronitrile with 1% mass of stearyl acrylate as an initiator, the prepared water-in-oil type high internal phase emulsion was transferred to a mold and left to react for 1 day under the protection of a nitrogen atmosphere. The porous polymer is prepared; the porous polymer is ground to a particle size range of 100 nm to 10 μm to obtain the pour point depressant and wax preventive agent 1.

Embodiment 2

[0060] 24mL of cetyl acrylate (reaction monomer), divinylbenzene (crosslinking agent) of 5% of the cetyl acrylate mass, Span-80 (emulsifier) of 30% of the cetyl acrylate mass ) heating and melting at 60° C. to obtain the first mixture;

[0061] The first mixture was emulsified with 76 mL of distilled water for 30 min under stirring to prepare a water-in-oil type high internal phase emulsion;

[0062] Using 1% azobisisobutyronitrile by mass of cetyl acrylate as an initiator, the prepared water-in-oil type high internal phase emulsion was transferred to a mold and left to react for 1 day under the protection of a nitrogen atmosphere. The porous polymer is prepared; the porous polymer is ground to a particle size range of 100 nm to 10 μm to obtain the pour point depressant and wax preventive agent 2.

Embodiment 3

[0064] 22mL of eicosyl acrylate (reactive monomer), divinylbenzene (crosslinking agent) of 10% of said eicosyl acrylate mass, Span-80 (emulsifier) of 30% of said eicosyl acrylate mass ) heating and melting at 80°C to obtain the first mixture;

[0065] The first mixture was emulsified with 78 mL of distilled water for 30 min under stirring to prepare a water-in-oil type high internal phase emulsion;

[0066] Using 1% azobisisobutyronitrile by mass of the eicosyl acrylate as an initiator, the prepared water-in-oil type high internal phase emulsion was transferred to a mold and left to react for 1 day under the protection of a nitrogen atmosphere. The porous polymer is prepared; the porous polymer is ground to a particle size range of 100 nm to 10 μm to obtain the pour point depressant and wax preventive agent 3.

[0067] Take the pour point depressant and wax preventive agent 1 as an example to test the effect of the present application's pour point depressant and wax prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com