Method for preparing colloidal crystal by emulsion suspension

A technology of colloidal crystals and emulsions, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of complex equipment, complex operation, low coating efficiency, etc., to achieve improved surface uniformity, simple preparation process, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

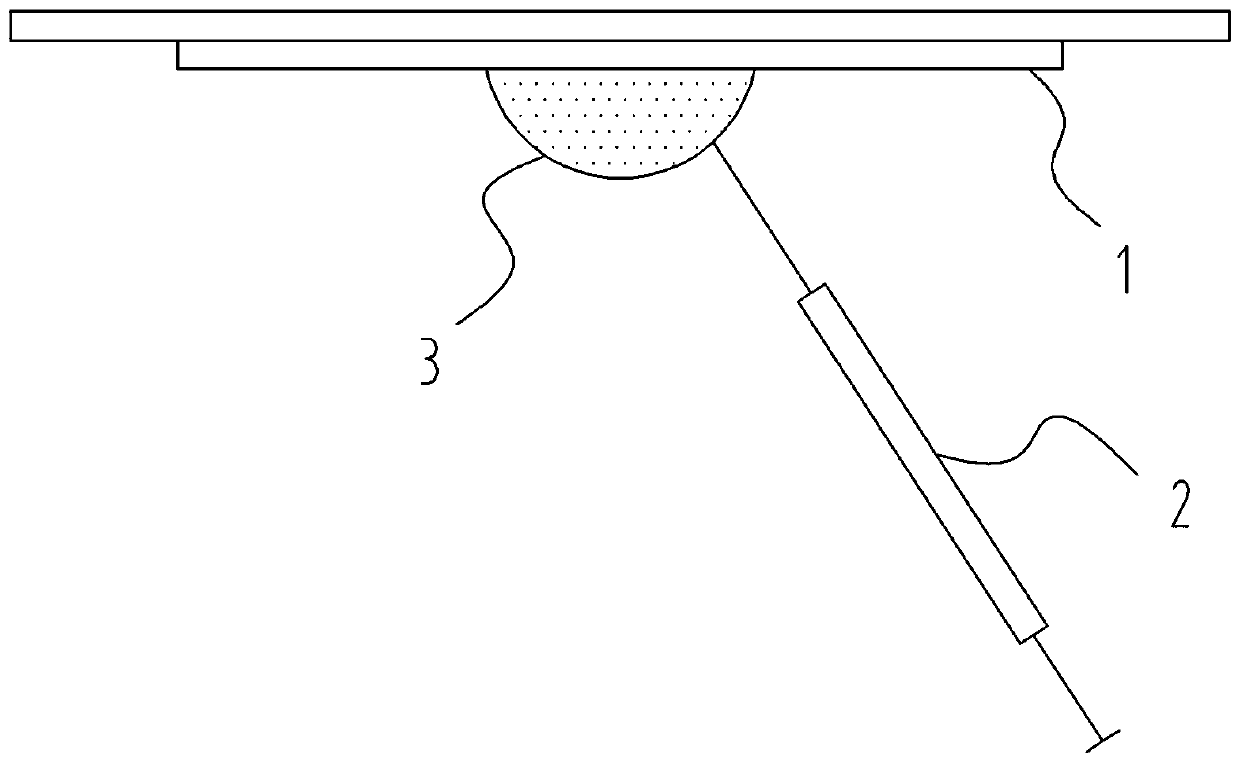

[0019] Such as figure 1 Shown, the present invention provides a kind of emulsion suspension and prepares the method for colloidal crystal, comprises the following steps:

[0020] S1, preparing latex particle suspension emulsion; using deionized water as the dispersion liquid, dispersing to obtain a polystyrene colloid particle suspension microemulsion with a solid content of 0.1%;

[0021] S2. The hydroxylated glass substrate is used as the substrate 1 to be coated, and the coating area is selected as 1cm 2 , injecting 40ul of colloidal particle suspoemulsion to the lower surface of the substrate to be coated with a micro injector 2, under the attraction force of the substrate to be coated 1 to the suspoemulsion, the suspoemulsion 3 is suspended on the lower surface of the substrate to be coated 1;

[0022] S3, combine figure 2 and image 3 As shown, the substrate to be coated with the suspended emulsion is moved into an oven at 40°C to evaporate the dispersion in the susp...

Embodiment 2

[0024] The invention provides a method for preparing colloidal crystals by suspension of emulsion, comprising the following steps:

[0025] S1, preparing latex particle suspension emulsion; using ethanol as the dispersion liquid, dispersing to obtain a silica colloidal particle suspension microemulsion with a solid content of 5%;

[0026] S2. Use the hydroxylated glass substrate as the substrate to be coated, and the coating area is selected as 1cm 2 , injecting 40ul colloidal particle suspoemulsion to the lower surface of the substrate to be coated with a micro injector, under the attraction force of the substrate to be coated to the suspoemulsion, the suspoemulsion is suspended on the lower surface of the substrate to be coated;

[0027] S3. Move the substrate to be coated with the suspended emulsion into a vacuum tube furnace at 150°C to evaporate the dispersion in the suspension, and the nanoparticles will be regularly discharged under the action of the capillary force gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com