A compound surfactant with ultra-low oil-water interfacial tension and preparation method thereof

A technology of oil-water interfacial tension and surfactant, applied in the field of compound surfactant and its preparation, compound surfactant for oil displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a composite surfactant with ultra-low oil-water interfacial tension, comprising the following steps:

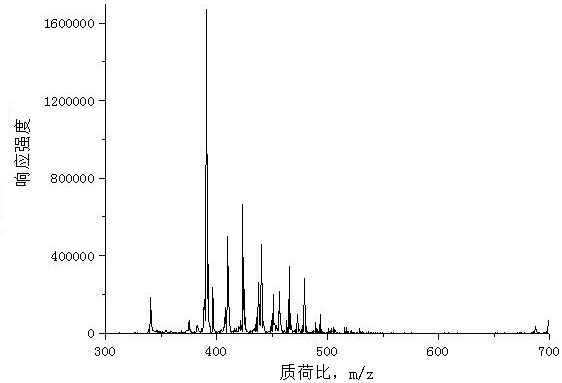

[0032] (1) Synthesis of alkylbenzene sulfonate:

[0033] ①Synthesis of light alkylbenzene sulfonate: take 20g of low molecular weight industrial alkylbenzene with a molecular weight of 330, put it in a three-necked bottle, and keep the temperature in an oil bath at 50°C; weigh 50g of fuming sulfuric acid, place Slowly add it dropwise into a three-necked flask to carry out sulfonation reaction, and at the same time carry out magnetic stirring; after reacting for 60 minutes, dissolve the reaction product in 20% sodium hydroxide solution for neutralization reaction to obtain light alkylbenzene Sulfonate;

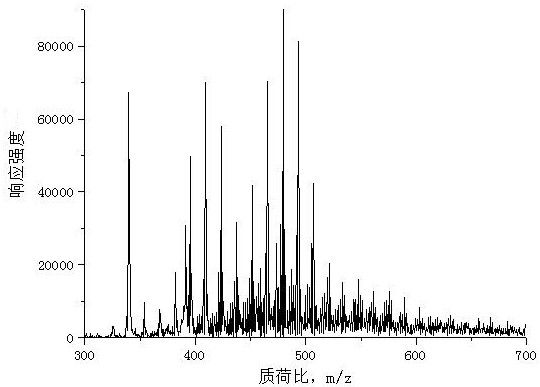

[0034] ②Synthesis of heavy alkylbenzene sulfonate: Take 20g of high-molecular-weight industrial alkylbenzene with a molecular weight of 410, put it in a three-necked bottle, and keep the temperature in an oil bath at 50°C; weigh 50g of fuming su...

Embodiment 2

[0041] A preparation method of a composite surfactant with ultra-low oil-water interfacial tension, comprising the following steps:

[0042] (1) Synthesis of alkylbenzene sulfonate: same as Example 1.

[0043] (2) Purification of alkylbenzene sulfonate: same as Example 1.

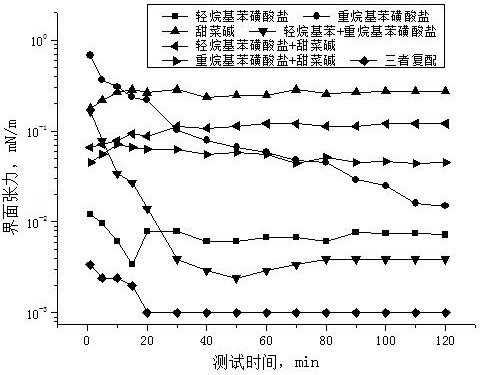

[0044] (3) Preparation of compound surfactant: add purified light alkylbenzene sulfonate, heavy alkyl benzene sulfonate and betaine into brine, stir evenly to obtain compound surfactant; The mass percentage of the components is as follows: 0.2% of light alkylbenzene sulfonate, 0.2% of heavy alkylbenzene sulfonate and 0.15% of betaine, and the balance is brine; the salinity of brine is 5000mg / L.

[0045] (4) Evaluation of interfacial activity: the oil-water interfacial tension of the compound surfactant is 6×10 -4 mN / m.

Embodiment 3

[0047] A preparation method of a composite surfactant with ultra-low oil-water interfacial tension, comprising the following steps:

[0048] (1) Synthesis of alkylbenzene sulfonate: same as Example 1.

[0049] (2) Purification of alkylbenzene sulfonate: same as Example 1.

[0050] (3) Preparation of compound surfactant: add purified light alkylbenzene sulfonate, heavy alkyl benzene sulfonate and betaine into brine, stir evenly to obtain compound surfactant; The mass percentage of the components is as follows: 0.3% of light alkylbenzene sulfonate, 0.3% of heavy alkylbenzene sulfonate and 0.2% of betaine, and the balance is brine; the salinity of brine is 2000mg / L.

[0051] (4) Evaluation of interfacial activity: the oil-water interfacial tension of the compound surfactant is 8×10 -4 mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com