Recycling method of foamed magnesium

A recovery method and foam magnesium technology are applied in the recovery field of foam magnesium, which can solve the problems of polluting the environment and harming the human body, and achieve the effects of high recovery rate, low cost, and promoting heterogeneous nucleation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

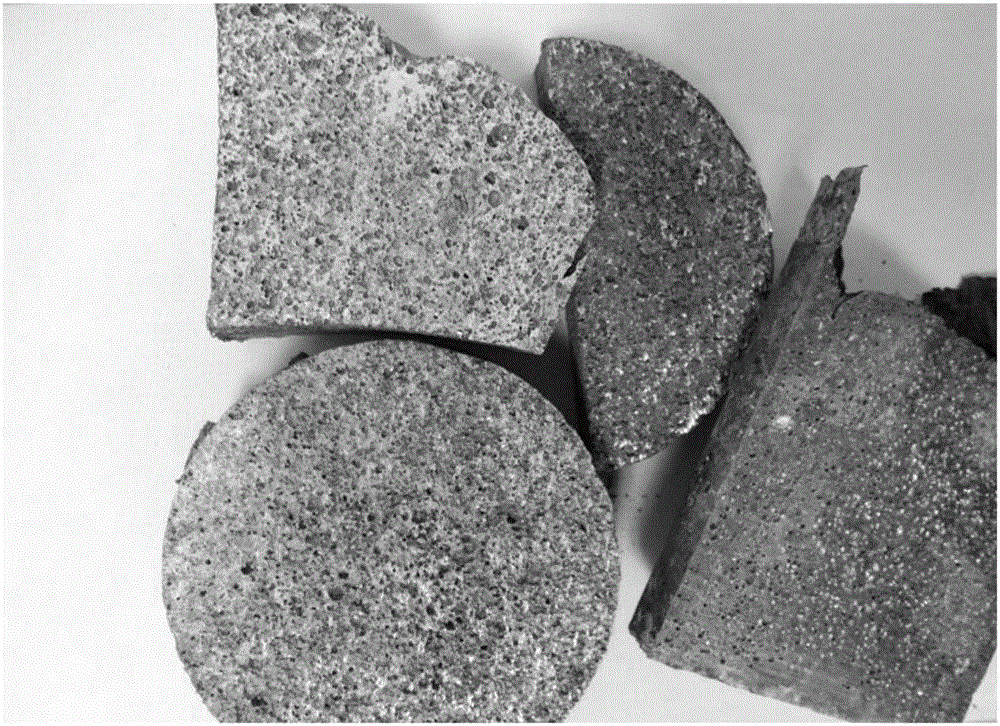

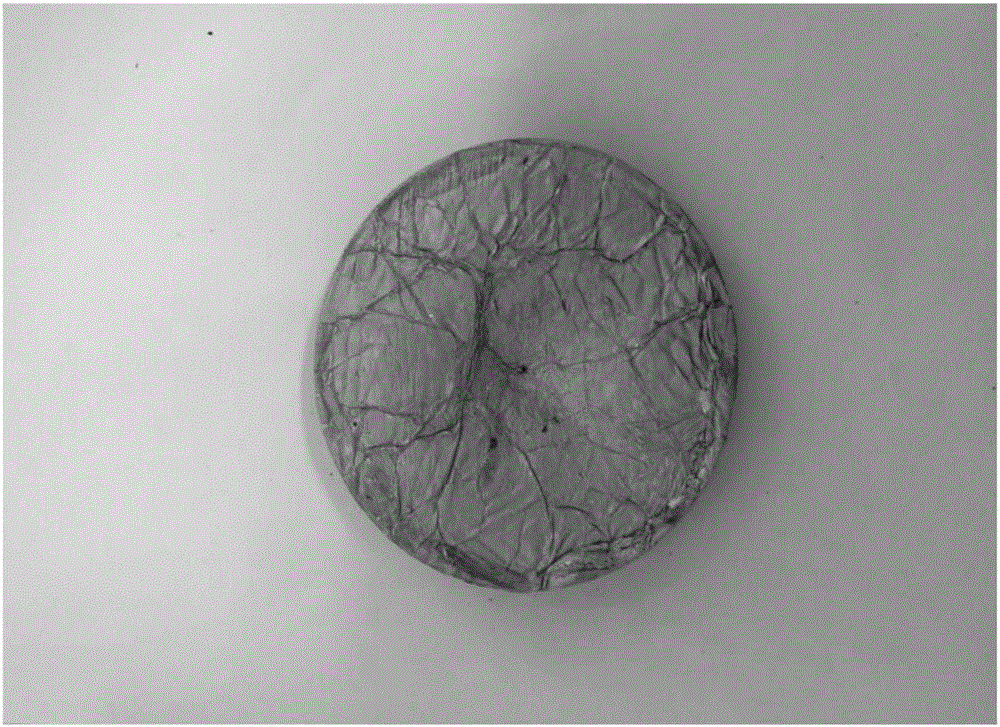

Image

Examples

Embodiment 1

[0025] The first step: clean the surface of the foamed magnesium, dry it until the water evaporates completely, and weigh its mass as 1000g;

[0026] The second step: mix hexachloroethane and 1% pure aluminum powder accounting for 0.3% of the total mass fraction of foamed magnesium, and press it to a density of 2.4g / cm 3 metamorphic block;

[0027] The third step: Put the dried magnesium foam into the crucible, and spread a layer of flux CaF on the surface of the foam magnesium 2 , whose mass is 20% of the mass fraction of foamed magnesium, the temperature of the crucible is raised to 720°C, and the volume ratio of 100:1 is fed into CO 2 and SF 6 Protect the gas, melt the foamed magnesium and keep it warm for 10 minutes to make the melt temperature uniform;

[0028] Step 4: Put in the stirring paddle and stir for 2 minutes at a speed of 200r / min to disperse the slag, and then add the metamorphic block produced in the second step to the melt;

[0029] Step 5: Feed Ar gas (p...

Embodiment 2

[0034] The first step: clean the surface of the foamed magnesium, dry it until the water evaporates completely, and weigh its mass as 1205g;

[0035] The second step: mix hexachloroethane and 2% pure aluminum powder accounting for 0.5% of the total mass fraction of foamed magnesium, and press it to a density of 2.7g / cm 3 metamorphic block;

[0036] The third step: Put the dried magnesium foam into the crucible, and spread a layer of flux CaF on the surface of the foam magnesium 2 , whose mass is 30% of the mass fraction of foamed magnesium, the temperature of the crucible is raised to 720°C, and the volume ratio of 50:1 is fed into the CO 2 and SF 6 The protective gas is used to melt the foamed magnesium and keep it warm for 15 minutes to make the temperature of the melt uniform;

[0037]Step 4: Put in the stirring paddle, and stir at a speed of 300r / min for 3 minutes to disperse the slag, and then add the metamorphic block produced in the second step to the melt;

[0038]...

Embodiment 3

[0041] The first step: clean the surface of the foamed magnesium, dry it until the water evaporates completely, and weigh its mass as 850g;

[0042] The second step: mix hexachloroethane and 1.5% pure aluminum powder accounting for 0.4% of the total mass fraction of foamed magnesium, and press it to a density of 2.5g / cm 3 metamorphic block;

[0043] The third step: Put the dried magnesium foam into the crucible, and spread a layer of flux CaF on the surface of the foam magnesium 2 , whose mass is 15% of the mass fraction of foamed magnesium, the temperature of the crucible is raised to 750°C, and at the same time, SF 6 and CO 2 Protect the gas, melt the foamed magnesium and keep it warm for 10 minutes to make the melt temperature uniform;

[0044] Step 4: Put in the stirring paddle, and stir at a speed of 100r / min for 2 minutes to disperse the slag, and then add the metamorphic block produced in the second step to the melt;

[0045] Step 5: Feed Ar gas (purity 99.999%) int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com