Aluminum-magnesium alloy slag removing agent, method for producing aluminum-magnesium alloy ingot and aluminum-magnesium alloy ingot

An aluminum-magnesium alloy and slag-removing agent technology, applied in the field of chemistry, can solve problems such as economic loss of enterprises and loss of metal resources, and achieve the effects of improving product quality, reducing metal loss and achieving good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

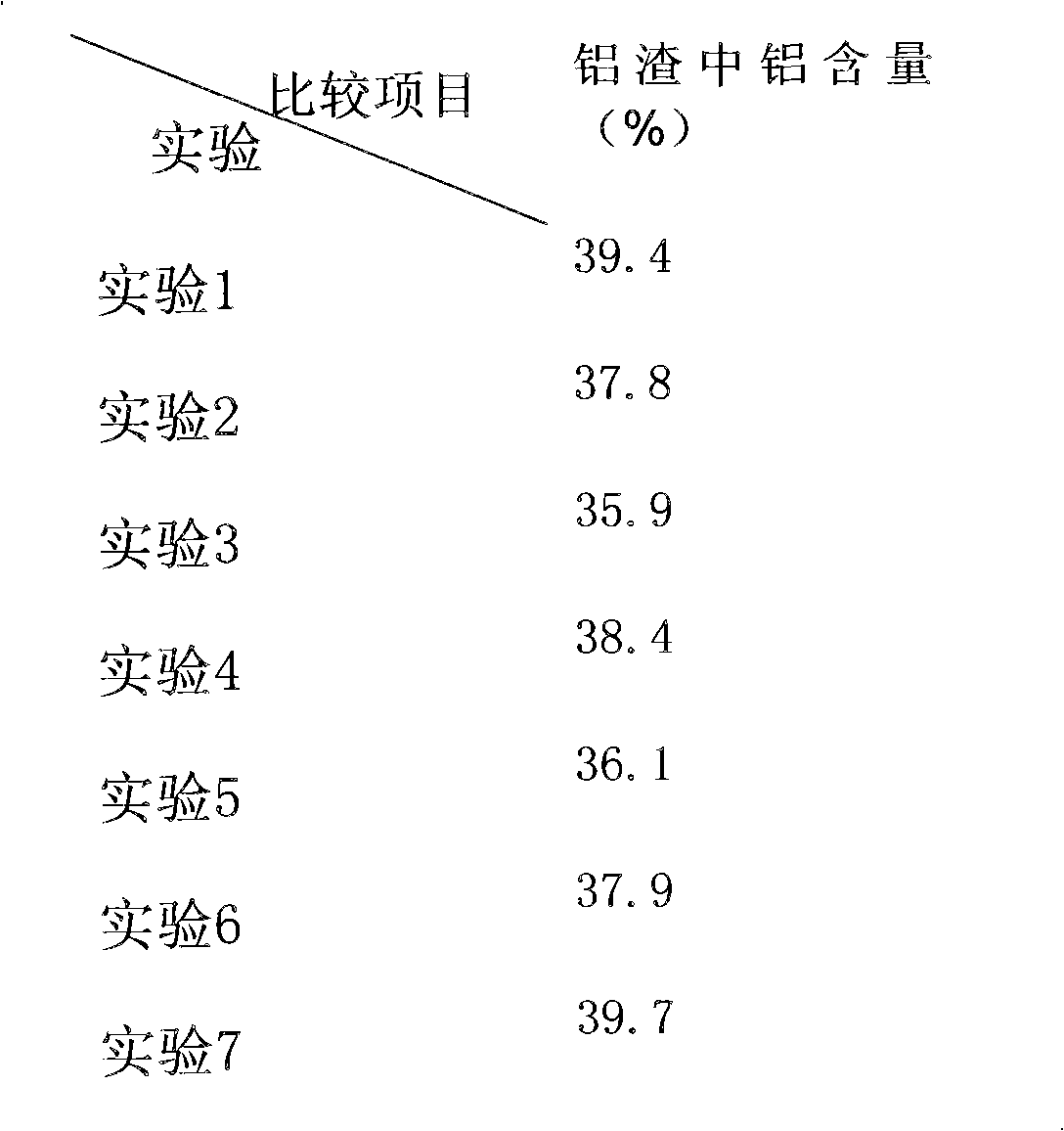

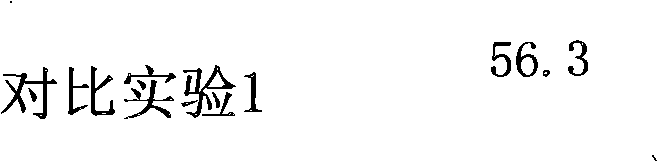

[0012] Embodiment 1.KCl (40%), MgCl 2 (40%), K 3 AlF 6 (20%)

[0013] In the production process of aluminum-magnesium alloy ingots with high magnesium content such as 5052 and 5083, the slag-removing agent containing the above ratio is taken from the packaging bag and added to the aluminum-magnesium alloy smelting process. Others are the same as conventional aluminum-magnesium alloy casting Ingot production process, detection of aluminum content in aluminum slag.

Embodiment 2

[0014] Embodiment 2.KCl (45%), MgCl 2 (35%), K 3 AlF 6 (20%)

[0015] In the production process of aluminum-magnesium alloy ingots with high magnesium content such as 5052 and 5083, the slag-removing agent containing the above ratio is taken from the packaging bag and added to the aluminum-magnesium alloy smelting process. Others are the same as conventional aluminum-magnesium alloy casting Ingot production process, detection of aluminum content in aluminum slag.

Embodiment 3

[0016] Embodiment 3.KCl (50%), MgCl 2 (30%), K 3 AlF 6 (20%)

[0017] In the production process of aluminum-magnesium alloy ingots with high magnesium content such as 5052 and 5083, the slag-removing agent containing the above ratio is taken from the packaging bag and added to the aluminum-magnesium alloy smelting process. Others are the same as conventional aluminum-magnesium alloy casting Ingot production process, detection of aluminum content in aluminum slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com