Biogas slurry pretreatment method and device for foliar fertilizer and drip irrigation fertilizer

A drip irrigation and foliar fertilizer technology, applied in fertilization devices, chemical instruments and methods, biological organic part treatment, etc., can solve the problems of biogas slurry being unable to absorb serious pollution, waste of biogas slurry resources, and blockage of equipment by biogas slurry. Achieve the effect of good pretreatment effect, labor saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

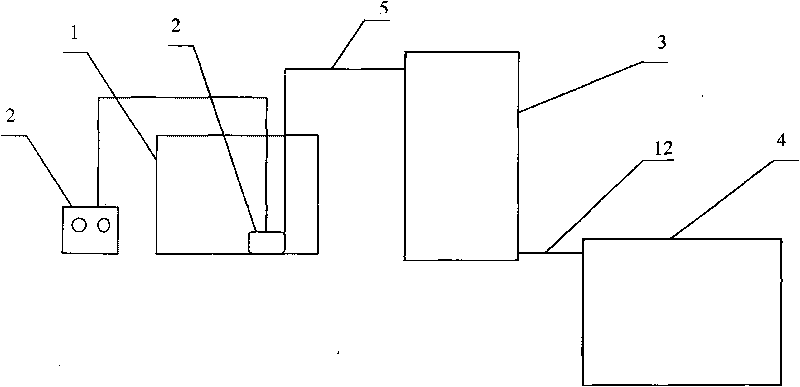

[0026] Embodiment 1: 10m of cow dung as raw material in the vegetable greenhouse 3 Underground hydraulic biogas tank biogas slurry pretreatment device

[0027] Biogas slurry is extracted every 2 months, and the amount of biogas slurry extracted is 2m 3 , the specific device design and method are as follows:

[0028] (1) Biogas slurry collection tank 1 is made of brick concrete, with a volume of 2m 3 ;

[0029] (2) According to the amount of biogas slurry 34L / d, the size of the designed biogas slurry pretreatment tank 3 is length × width × height = 1.0m × 0.85m × 0.8m, and the volume is 0.68m 3 , the material is brick concrete, the amount and time of the biogas slurry entering the pretreatment tank are strictly controlled by the control device, 4 times a day, the amount of biogas slurry entering each time is 8.5L, and the time of entering the biogas slurry is 8:30 and 11:00 every day 30, 14:30 and 17:30.

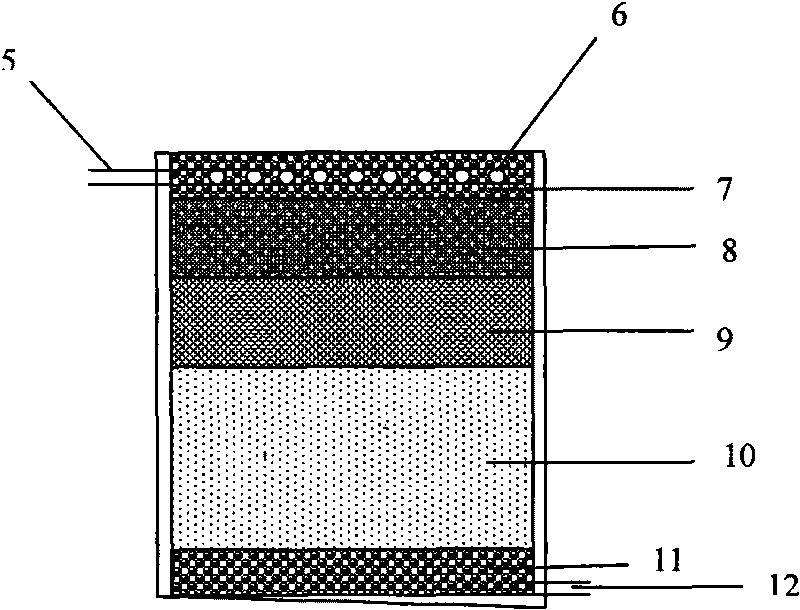

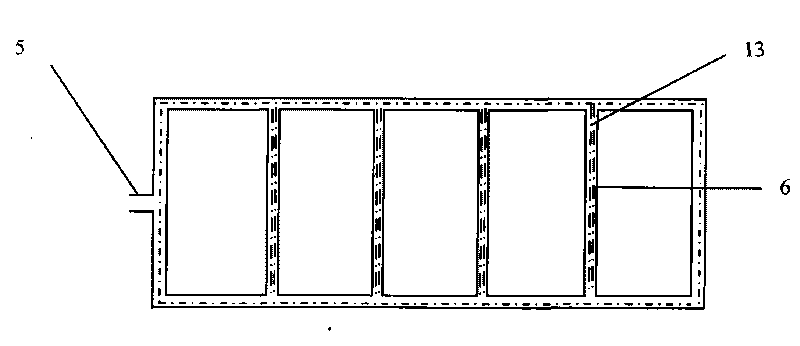

[0030] The structure of the device is as figure 1 , 2 As shown, ...

Embodiment 2

[0035] Embodiment 2: 20m of cow dung as raw material in the vegetable greenhouse 3 Underground hydraulic biogas tank biogas slurry pretreatment device

[0036] Biogas slurry is extracted once every 2 months, and the volume of each biogas slurry extraction is 4m 3 , the specific device design and method are as follows:

[0037] (1) Biogas slurry collection tank 1 is made of fiberglass and has a volume of 4m 3 ;

[0038] (2) According to the amount of biogas slurry 67L / d, the size of biogas slurry pretreatment tank 3 is designed to be length × width × height = 1.0m × 1.7m × 0.8m, and the volume is 1.36m 3 , the material is glass fiber reinforced plastic structure, the amount and time of biogas slurry entering the pretreatment tank are strictly controlled by the control device, 4 times a day, the amount of biogas slurry entering each time is 16.75L, and the time of entering the biogas slurry is 8:30 and 11:00 every day 30, 14:30 and 17:30.

[0039] The structure of the device ...

Embodiment 3

[0041] Embodiment 3: 50m of cow dung as raw material in the vegetable greenhouse 3 Underground hydraulic biogas tank biogas slurry pretreatment device

[0042] Biogas slurry is extracted once every 2 months, and the amount of biogas slurry pumped each time is 10m 3 , the specific device design and method are as follows:

[0043] (1) Biogas slurry collection tank 1 is made of brick concrete or fiberglass, with a volume of 10m 3 ;

[0044] (2) According to the amount of biogas slurry 167L / d, the size of biogas slurry pretreatment tank 3 is designed as length X width X height = 2.5mX1.68mX0.8m, volume is 3.36m 3 , the material is brick-concrete or fiberglass structure, the amount and time of biogas slurry entering the pretreatment tank are strictly controlled by the control device, 4 times a day, the amount of biogas slurry entering each time is 41.75L, and the time of entering the biogas slurry is 8:30 every day , 11:30, 14:30 and 17:30.

[0045] The structure of the device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com