Vegetable washer

A washing machine and vegetable technology, applied in application, food processing, food science and other directions, can solve the problems of large water consumption, high labor intensity of operators, low vegetable yield, etc., and achieves high yield, improved vegetable washing efficiency, The effect of shortening the washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

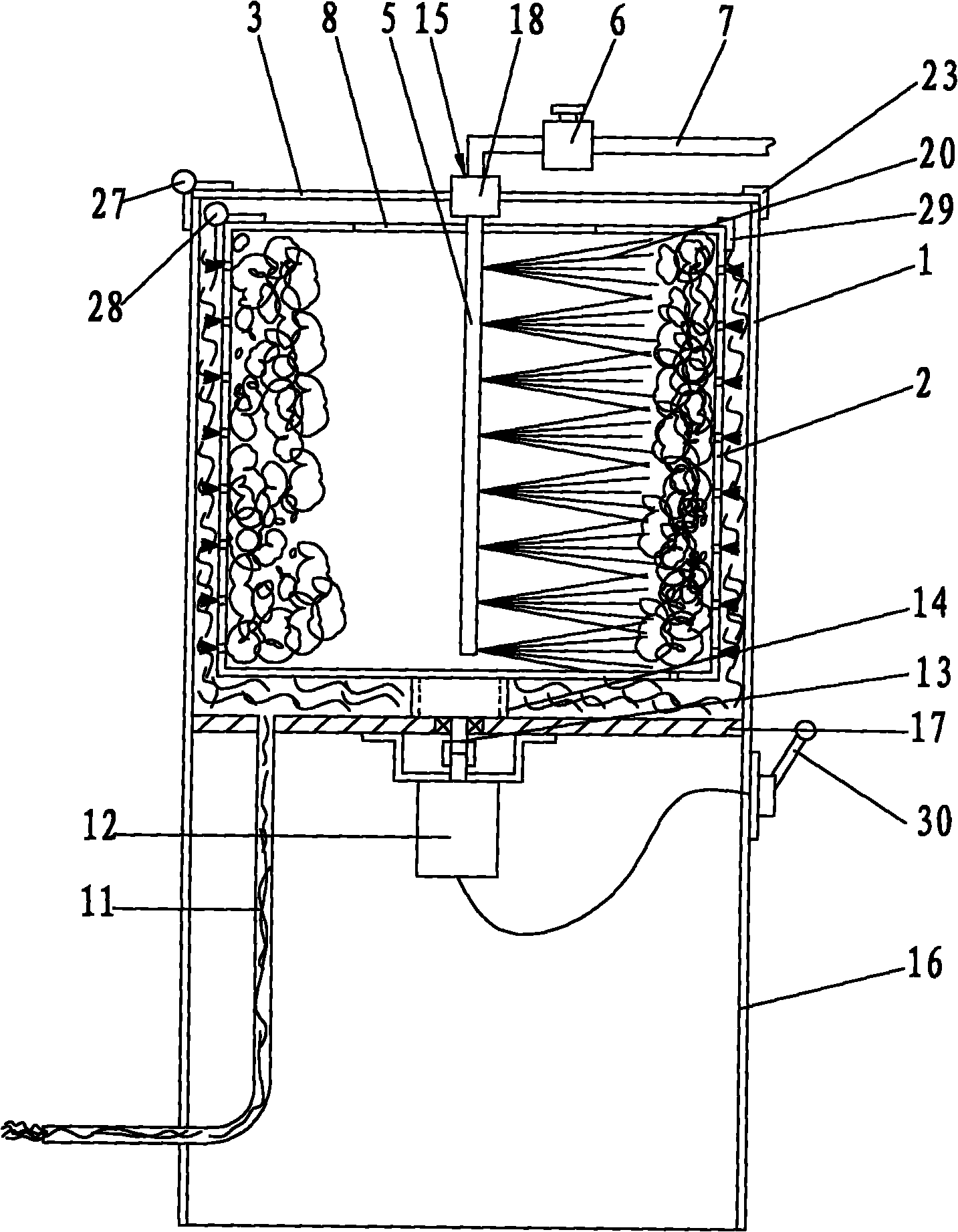

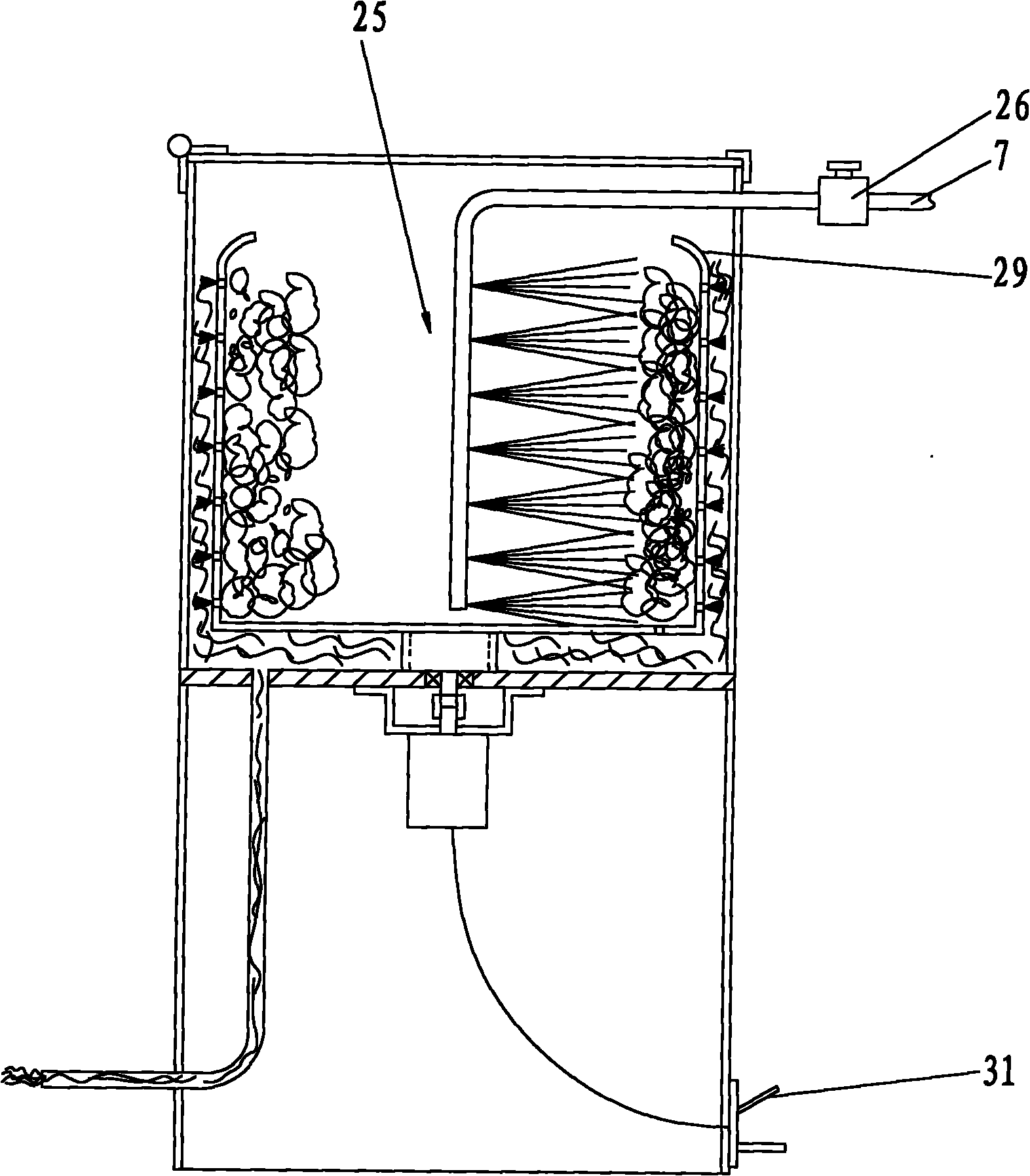

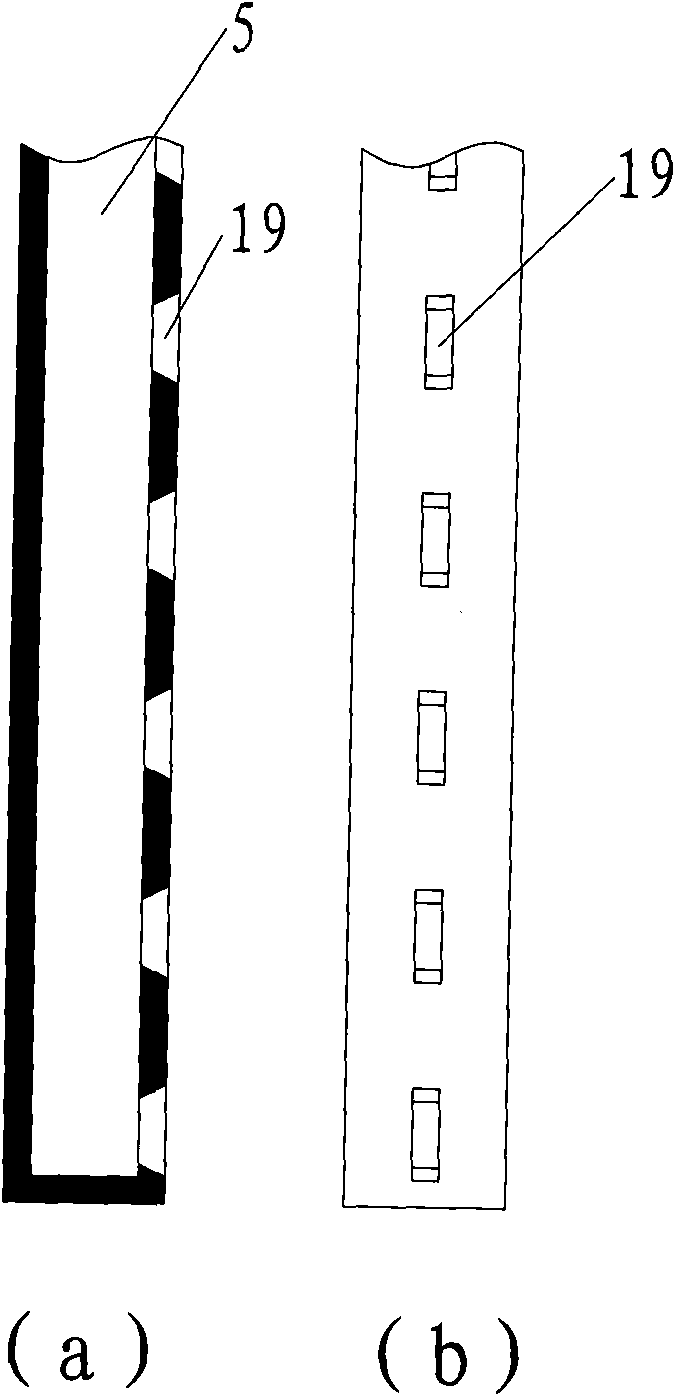

[0027] The specific embodiment of the vegetable washing machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] Such as figure 1As shown, the vegetable washing machine of the first embodiment of the present invention includes an outer tub 1, an inner tub 2, a motor 12, and a water spray mechanism 15, an outer cover 3, and an inner cover 8, and the outer tub 1 is the shell of the vegetable washing machine. Partly, in this embodiment, the casing is composed of the outer tub 1 and the base 16 for supporting the outer tub 1, and the outer tub 1 and the base 16 are integrally formed in a cylindrical shape. A horizontal spacer plate 17 perpendicular to the central axis of the cylinder is welded at the roughly middle position of the cylinder with openings at both ends or at a position lower than the middle position, and the cylinder is divided into upper and lower parts, and the upper part constitutes the outer part. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com